Method for preparing nutrients from sea cucumber water decoction

The technology of boiled liquid and nutrient agent is applied in the field of sea cucumber boiled liquid processing technology, which can solve the problems of loss of nutrients and environmental pollution, and achieve the effects of promoting fibrinolysis, improving immunity and inhibiting the formation of embolism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

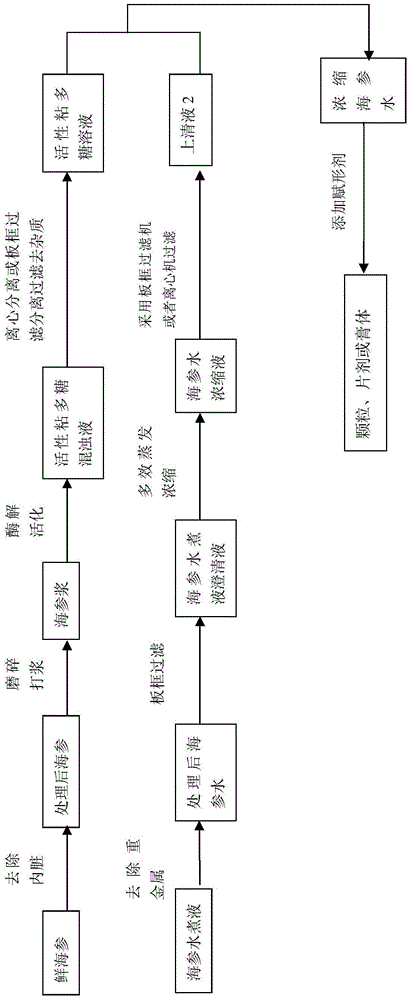

Image

Examples

Embodiment 1

[0015] Sea cucumber boiled liquid is processed into oral liquid, adopts following processing technology, comprises the following steps:

[0016] a. Take the sea cucumber boiled liquid in the sea cucumber processing process, and remove the heavy metal ions in the sea cucumber boiled liquid by ion exchange method, using Purolite S-950, Imac TMR, D301, Dowex 50x8 and other ion exchange resin materials. Take a glass column with an inner diameter of 50cm, and put it on the column by dry method. Taking D301 as an example, use 1g of ion exchange resin for every 1ml of sea cucumber boiled liquid. Elute with aqueous hydrochloric acid pH 6.5.

[0017] b. Filter the eluent in step a with a plate and frame filter, and the plate and frame filter fineness is 120 mesh

[0018] c. Further concentrate the solution obtained in step b with a multi-effect evaporator until the solid content is 50g / 100ml;

[0019] D, adopt plate and frame filter or centrifuge to filter and obtain sea cucumber wat...

Embodiment 2

[0029] The preparation of the oral solution comprises the steps of:

[0030] a. Take the sea cucumber boiled liquid in the sea cucumber processing process, and remove the heavy metal ions in the sea cucumber boiled liquid by ion exchange method, using D301 plasma ion exchange resin material. Take a metal column with an inner diameter of 35cm, put it on the column by dry method, and use 1g of ion exchange resin for every 1ml of sea cucumber boiled liquid. Elute with aqueous hydrochloric acid pH 6.5.

[0031] b. Filter the eluent in step a with a plate and frame filter, and the plate and frame filter fineness is 180 mesh

[0032] c. Further concentrate the solution obtained in step b with a multi-effect evaporator until the solid content is 36g / 100ml;

[0033] D, adopt plate and frame filter or centrifuge to filter and obtain sea cucumber water concentrate;

[0034] e. Prepare sea cucumber enzymatic hydrolysis solution, take fresh sea cucumbers and grind them into pulp, add b...

Embodiment 3

[0038] a. Take the sea cucumber boiled liquid in the sea cucumber processing process, and remove the heavy metal ions in the sea cucumber boiled liquid by ion exchange method, using Dowex 50x8 ion exchange resin material. Take a metal column with an inner diameter of 45cm, put it on the column by dry method, and use 12g of ion exchange resin for every 1ml of sea cucumber boiled liquid. Elute with aqueous hydrochloric acid pH 6.5.

[0039] B, the eluent in step a is filtered with a plate and frame filter, and the plate and frame filter fineness is 100 mesh;

[0040] c. Further concentrate the solution obtained in step b with a multi-effect evaporator until the solid content is 10g-60g / 100ml;

[0041] D, adopt plate and frame filter or centrifuge to filter and obtain sea cucumber water concentrate;

[0042] e. Prepare sea cucumber enzymatic hydrolysis solution, take fresh sea cucumbers and grind them into pulp, add biological enzymes, such as Bacillus subtilis neutral protease...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com