Preparation method for letrozole tablets with good stability

A technology for the stability of letrozole tablets, which is applied in the field of preparation of letrozole tablets, can solve the problems of easy sticking and punching, poor stability of letrozole tablets, etc., and achieves improved stability, improved dissolution rate and stable sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

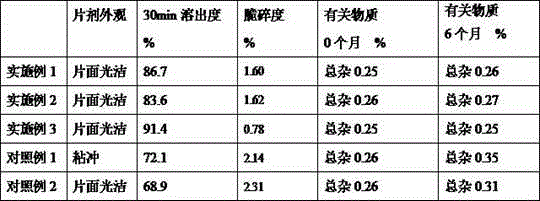

Examples

Embodiment 1

[0016] The preparation method of letrozole tablets, the steps are as follows: in parts by weight, 20 parts of letrozole are dissolved in 120 parts of ethanol, 5 parts of titanium oxide, 3 parts of heavy magnesium carbonate and 10 parts of micropowdered silica gel are added, and the pressure is reduced at 25 ° C. Evaporate ethanol to dryness, take out the evaporated composition, and then add 70 parts of filler microcrystalline cellulose, 5 parts of disintegrant sodium carboxymethyl starch, and 4 parts of lubricant magnesium stearate after passing through an 80-mesh sieve, and mix well , obtained after direct compression, each tablet weighs 0.25g.

Embodiment 2

[0018] The preparation method of letrozole tablets, the steps are as follows: in parts by weight, 30 parts of letrozole are dissolved in 180 parts of ethanol, 10 parts of titanium oxide, 6 parts of heavy magnesium carbonate and 20 parts of micropowdered silica gel are added, and the pressure is reduced at 40 ° C. Evaporate ethanol to dryness, take out the evaporated composition, and then add 90 parts of filler microcrystalline cellulose, 10 parts of disintegrant sodium carboxymethyl starch, and 8 parts of lubricant magnesium stearate after passing through an 80-mesh sieve, and mix well , obtained after direct compression, each tablet weighs 0.25g.

Embodiment 3

[0020] The preparation method of letrozole tablets, the steps are as follows: in parts by weight, 25 parts of letrozole are dissolved in 160 parts of ethanol, 7 parts of titanium oxide, 5 parts of heavy magnesium carbonate and 15 parts of micropowdered silica gel are added, and the pressure is reduced at 30 ° C. Evaporate ethanol to dryness, take out the evaporated composition, and then add 80 parts of filler microcrystalline cellulose, 8 parts of disintegrant sodium carboxymethyl starch, and 6 parts of lubricant magnesium stearate after passing through an 80-mesh sieve, and mix well , obtained after direct compression, each tablet weighs 0.25g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com