Method for extracting coenzyme Q10 from fermentation mycelia

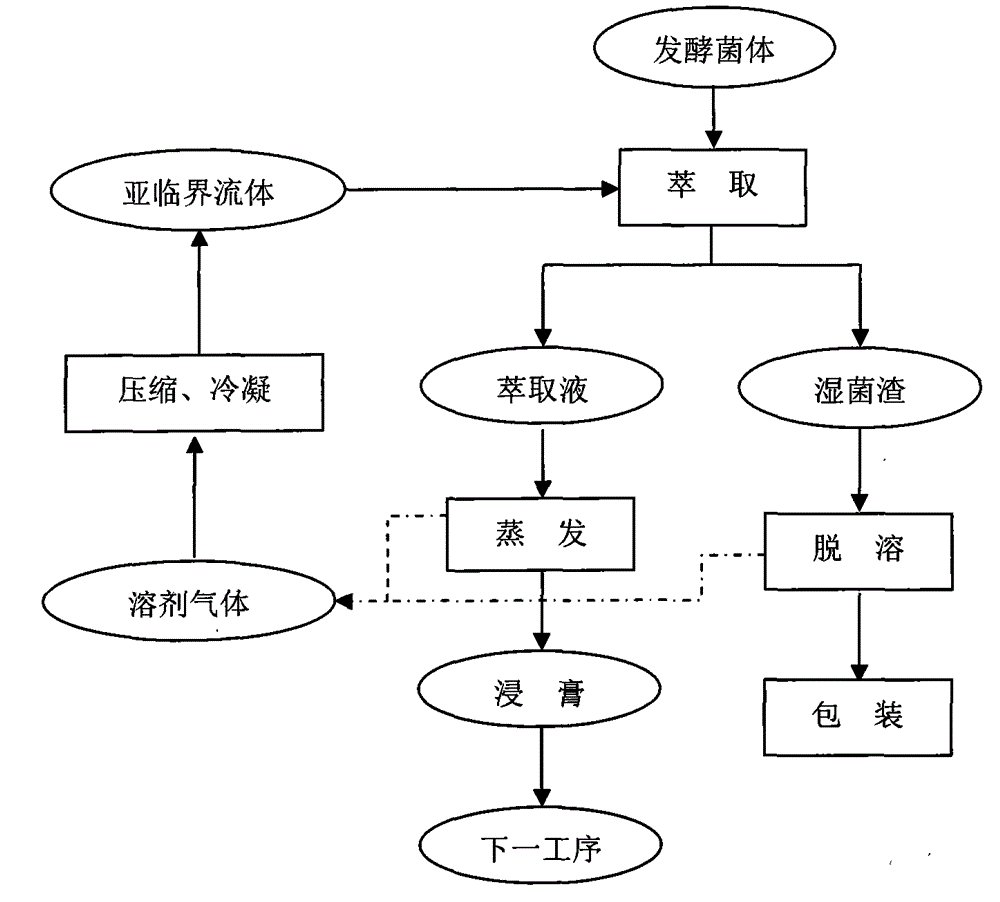

An extraction method and a technology of fermenting bacteria, which are applied in the field of extracting coenzyme Q10 in fermented bacteria, can solve the problems of low yield of organic solvent extraction, large investment in extraction equipment, and decline in product quality, and meet the requirements of large solvent diffusion coefficient and equipment requirements. Low, less solvent loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

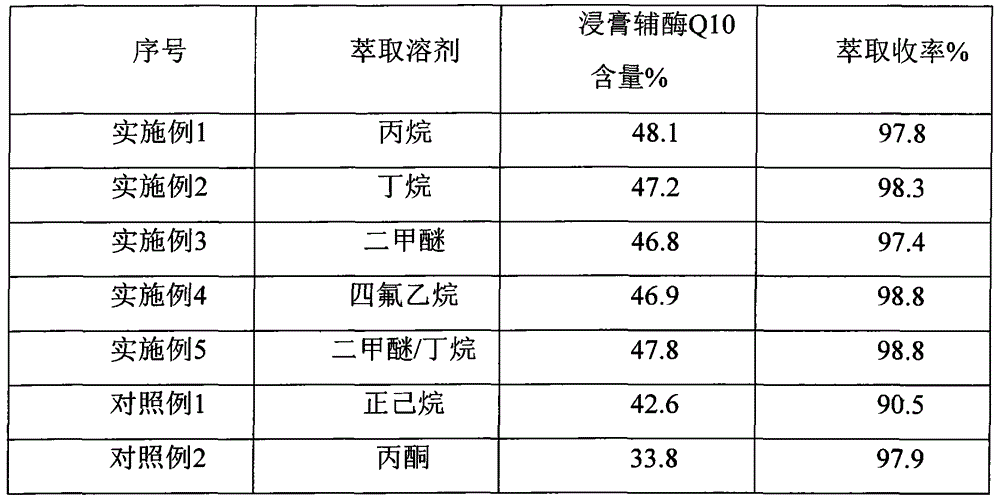

[0031] Embodiment 1. utilize subcritical propane fluid to extract coenzyme Q10

[0032]Weigh 500g of coenzyme Q10 bacterial sample (content 24.3mg / g), pulverize it with a pulverizer, the particle size is controlled between 10 and 120 mesh, put it in a closed extraction tank, close the feed valve, pump to vacuum, press the bacterial cell Weight (g) / solvent volume (ml) = 1 / 3 Inject propane solvent, stir and mix and extract 3 times under the conditions of temperature 20-25°C and pressure 0.85-0.88MPa, each time 30min; after the extraction is completed, transfer out For the extract in the extraction tank, open the outlet valve of the extraction tank for desolvation, heat the extraction tank with hot water, and stir, the heating temperature is 45-50 ° C, the stirring speed is 30 rpm, and the pressure of the extraction tank is reduced to 0 MPa , Start the vacuum pump for negative pressure evaporation until the pressure drops below -0.085MPa, stop the precipitation, open the nitrogen...

Embodiment 2

[0033] Embodiment 2. Utilize subcritical butane fluid to extract coenzyme Q10

[0034] Weigh 500g of coenzyme Q10 bacterial sample (content 24.3mg / g), pulverize it with a pulverizer, the particle size is controlled between 10 and 120 mesh, put it in a closed extraction tank, close the feed valve, pump to vacuum, press the bacterial cell Weight (g) / solvent volume (ml)=1 / 3 Inject the solvent, stir and mix and extract 3 times at a temperature of 25-30°C and a pressure of 0.30-0.35MPa, each time 20min; The method in 1 removes the solvent, takes out the sample, collects and obtains 25.30 g of coenzyme Q10 extract, the content of coenzyme Q10 in the extract is 47.2%, and the extraction yield is 98.3%.

Embodiment 3

[0035] Example 3. Utilize subcritical dimethyl ether fluid to extract coenzyme Q10

[0036] Weigh 500g of coenzyme Q10 bacterial sample (content 24.3mg / g), pulverize it with a pulverizer, the particle size is controlled between 10 and 120 mesh, put it in a closed extraction tank, close the feed valve, pump to vacuum, press the bacterial cell Weight (g) / solvent volume (ml)=1 / 3 Inject dimethyl ether solvent, stir and mix and extract 3 times under the conditions of temperature 25-30°C and pressure 0.48-0.52MPa, each time 20min; after the extraction, Remove the solvent according to the method in Example 1, take out the sample, collect and obtain 25.28 g of coenzyme Q10 extract, the content of coenzyme Q10 in the extract is 46.8%, and the extraction yield is 97.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com