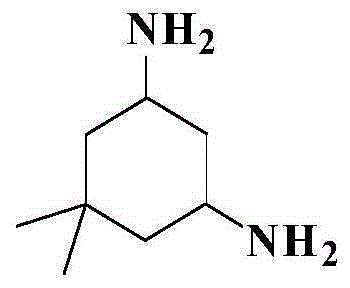

Preparation method of 5,5-dimethyl-1,3-cyclohexamethylenediamine

A technology of cyclohexanediamine and dimethyl, which is applied in the field of chemical synthesis, can solve the problems of being unsuitable for industrial production scale-up, low product yield and purity, and cumbersome post-treatment, and achieves benefits for scale-up of industrial production, low cost, and method novel effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

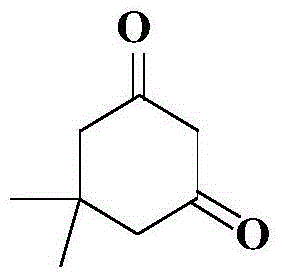

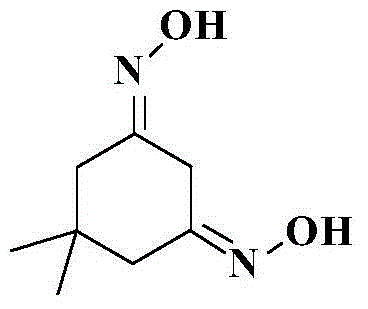

[0027] Step 1, the preparation of 5,5-dimethyl-1,3-cyclohexanedione

[0028] Add 64.4g (0.937mol) sodium ethylate, 138.4g (0.856mol) diethyl malonate, 80.0g (0.815mol) 4-methyl-3-penten-2-one, 257.8g absolute ethanol to In a 2L three-neck flask, stir and mix well, heat to reflux, and stir at reflux for 1 to 2 hours. TLC detects that 4-methyl-3-penten-2-one has reacted completely and there is no residue. Add a mixed solution of 123.0g (1.972mol) KOH and 566g tap water, and stir under reflux for 6-10h. Ethanol in the system was evaporated, and 300g4mol / L HCl aq was added dropwise to the remaining aqueous solution system to adjust the pH value of the system to 1-2, a yellow solid gradually precipitated in the system, cooled to room temperature, and suction filtered, the filter cake was a yellow solid, The filter cake was rinsed with tap water (100 g x 5). After the filter cake was dried, 90.0 g of light yellow granular solid was obtained, the yield was 78.8% (calculated as 4-me...

Embodiment 2

[0034] Step 1, the preparation of 5,5-dimethyl-1,3-cyclohexanedione

[0035] Add 50.6g (0.937mol) sodium methoxide, 138.4g (0.856mol) diethyl malonate, 80.0g (0.815mol) 4-methyl-3-penten-2-one, and 203g methanol to a 2L three-necked flask , stir and mix, heat to reflux, and stir at reflux for 1 to 2 hours. TLC detects that 4-methyl-3-penten-2-one has reacted completely and there is no residue. Add a mixed solution made of 78.9g (1.972mol) NaOH and 363g tap water, and stir under reflux for 6-10h. The methanol in the system was evaporated, and 300g4mol / L HCl aq was added dropwise to the remaining aqueous solution to adjust the pH value of the system to 1-2. A yellow solid gradually precipitated in the system, cooled to room temperature, and suction filtered. The filter cake was a yellow solid. Tap water (100g×5) rinses the filter cake. After the filter cake was dried, 88.5 g of light yellow granular solid was obtained, with a yield of 77.5% (calculated as 4-methyl-3-penten-2-o...

Embodiment 3

[0041] Step 1, the preparation of 5,5-dimethyl-1,3-cyclohexanedione

[0042] Add 76.9 g (0.937 mol) sodium isopropoxide, 138.4 g (0.856 mol) diethyl malonate, 80.0 g (0.815 mol) 4-methyl-3-penten-2-one, 269.8 g tetrahydrofuran to 2L In the three-neck flask, stir and mix well, heat to reflux, and stir at reflux for 1-2 hours. TLC detects that 4-methyl-3-penten-2-one has reacted completely and there is no residue. Add a mixed solution of 123.0g (1.972mol) KOH and 566g tap water, and stir under reflux for 6-10h. The tetrahydrofuran in the system was evaporated, and 300g4mol / L HCl aq was added dropwise to the remaining aqueous solution system to adjust the pH value of the system to 1-2. A yellow solid gradually precipitated in the system, cooled to room temperature, and suction filtered. The filter cake was a yellow solid. The filter cake was rinsed with tap water (100 g x 5). After the filter cake was dried, 87.2 g of a yellowish granular solid was obtained, with a yield of 76....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com