Color-variable additive composition, preparation method and application of color-variable additive composition

A technology of a composition and a color-changing aid, which is applied to the color-changing aid composition and the fields of its preparation and application, can solve the problems of limited chromatic aberration contrast, generation of flow marks or streaks, difficulty in forming color difference, etc., and achieves high chromatic aberration contrast, Improve chromatic aberration contrast, consistent marking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

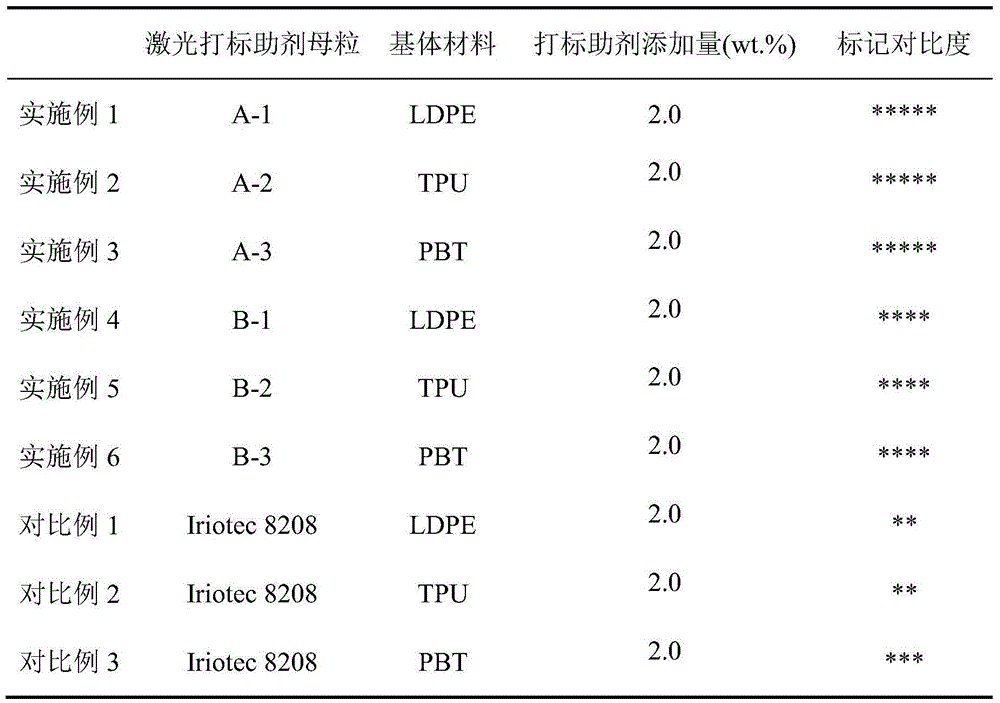

Examples

Embodiment 1

[0062] Metal powder (core): Ag, particle size (D 50 ) is 0.5 μm;

[0063] Thermoplastic polymer of the first shell: PA MDX6 (polyamide MDX6), Mitsubishi Engineering 1022H;

[0064] Compatibilizer for the second shell: ethylene-butyl acrylate-maleic anhydride copolymer, Akema, Lotader 3210;

[0065] Accelerator: dipentaerythritol phosphate (Guangzhou Ruidao Chemical Co., Ltd.)

[0066] Carrier polymer: high-density polyethylene, melt index 0.5g / 10min (190°C);

[0067] Mix 39.9 parts of PA MDX6, 60 parts of Ag powder, and 0.1 part of dipentaerythritol phosphate (parts by weight), and then use a twin-screw extruder to blend into a homogeneous mixture. The blending temperature is 240 ° C to 260 ° C;

[0068] Next, take 40.0 parts of the above mixture, 10.0 parts of ethylene-butyl acrylate-maleic anhydride copolymer, and 50.0 parts of high-density polyethylene (parts by weight) and continue mixing with a twin-screw extruder at a temperature of 180°C to 200°C; The core-shell str...

Embodiment 2

[0072] Metal powder (core): Zn, particle size (D 50 ) is 55 μm;

[0073] Thermoplastic polymer of the first shell: PC (polycarbonate), SABIC 241R

[0074] Compatibilizer for the second shell: ethylene-methyl acrylate-methacrylate glycidyl ether copolymer, Akema, Lotader AX8900;

[0075] Accelerator: zinc methyl ethyl phosphinate (Guangzhou Ruidao Chemical Co., Ltd.)

[0076] Carrier polymer: POE (ethylene-octene copolymer), Dupont 8150;

[0077] Mix 10.0 parts of PC, 85.0 parts of Zn powder, and 5.0 parts of zinc methyl ethyl phosphinate (parts by weight), and then use a twin-screw extruder to blend into a uniform mixture. The blending temperature is 250 ° C to 270 ° C;

[0078] Next, take 5.0 parts of the above mixture, 0.2 parts of ethylene-methyl acrylate-glycidyl methacrylate copolymer, and 94.8 parts of POE (parts by weight) and continue mixing with a twin-screw extruder at a temperature of 190°C to 220°C; The core-shell structure is formed in situ in the carrier POE,...

Embodiment 3

[0082] Metal powder (core): Al, particle size (D 50 ) is 15 μm;

[0083] Thermoplastic polymer for first shell: PPS (polyphenylene sulfide), Phillips R-7-02

[0084] Compatibilizer for the second shell: polypropylene grafted with glycidyl methacrylate, grafting rate 0.5wt%, melt index 11g / 10min (230°C);

[0085] Accelerator: aluminum diethylphosphinate (Guangzhou Ruidao Chemical Co., Ltd.)

[0086] Carrier polymer: iPP (isotactic polypropylene), Sinopec T30S

[0087] Mix 28.0 parts of PPS (-SH group exists at the end of the PPS molecular chain), 70.0 parts of Al powder, and 2.0 parts of aluminum diethylphosphinate (parts by weight), and then use a twin-screw extruder to blend into a homogeneous mixture. The blending temperature is 290°C to 320°C;

[0088]Next, take 25.0 parts of the above mixture, 3.0 parts of polypropylene grafted glycidyl methacrylate, and 72.0 parts of iPP (parts by weight) to continue mixing with a twin-screw extruder at a temperature of 250°C to 270°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt finger | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com