Chemical mechanical polishing liquid for titanium

A chemical machinery and polishing liquid technology, applied in the field of polishing liquid, can solve the problems of surface corrosion, difficult to control polishing speed, poor surface performance, etc., and achieve the effect of low surface corrosion, good surface quality and controllable rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

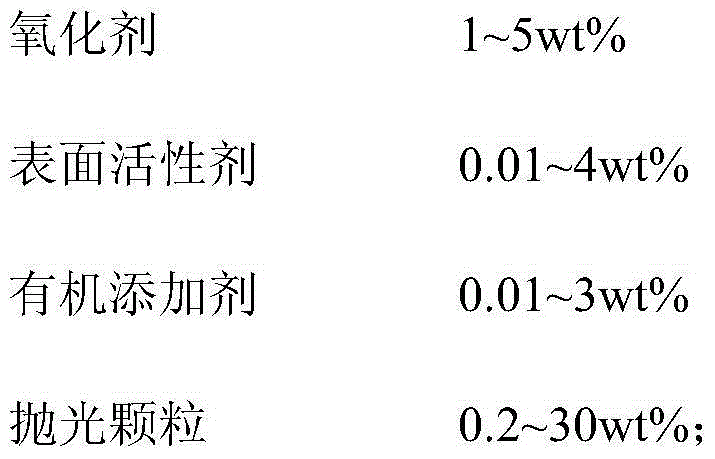

[0043] In this embodiment, the chemical mechanical polishing solution contains the following raw material components and parts by weight:

[0044]

[0045] The polishing particles described in this embodiment are silicon oxide particles; the particle size is 60 nm; the oxidizing agent is hydrogen peroxide; the pH regulator is nitric acid solution; the surfactant is sodium polyacrylate; the organic additive is glycine.

[0046] The chemical mechanical polishing solution has a pH of 1.

[0047] The chemical mechanical polishing fluid is obtained by stirring the above-mentioned raw material components evenly.

Embodiment 2

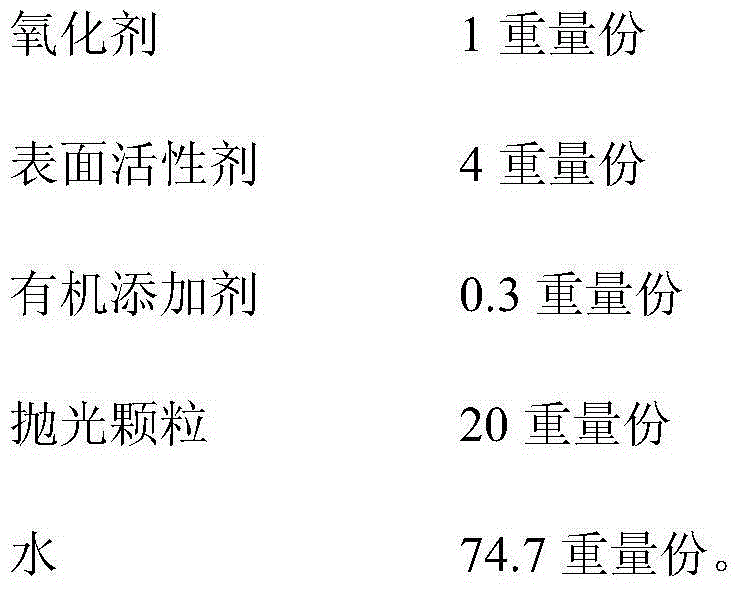

[0049] In this embodiment, the chemical mechanical polishing solution contains the following raw material components and parts by weight:

[0050]

[0051] The polishing particles described in this embodiment are titanium oxide particles; the particle size is 150 nm; the oxidant is potassium ferricyanide; the pH regulator is phosphoric acid; the surfactant is polyoxyethylene sodium sulfate; the organic additive is salicylic acid.

[0052] The pH of the chemical mechanical polishing solution is 5.

[0053] The chemical mechanical polishing fluid is obtained by stirring the above-mentioned raw material components evenly.

Embodiment 3

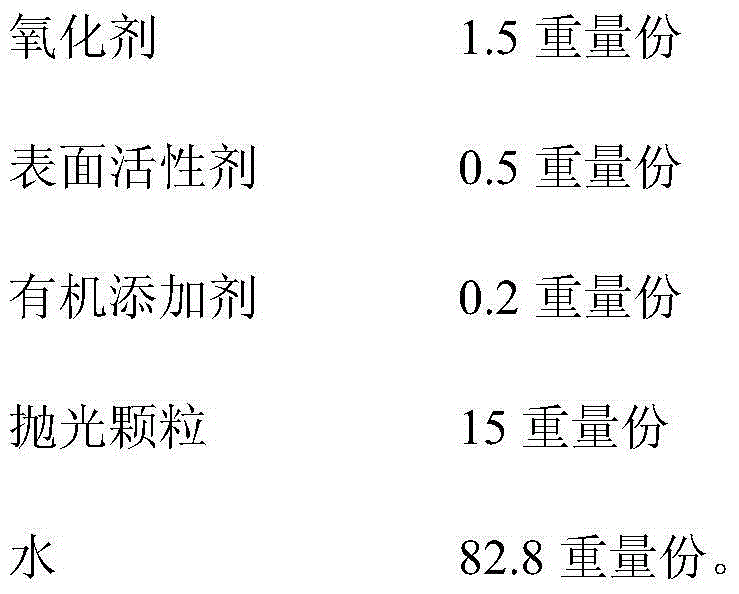

[0055] In this embodiment, the chemical mechanical polishing solution contains the following raw material components and parts by weight:

[0056]

[0057] The polishing particles described in this embodiment are alumina particles; the particle size is 80nm; the oxidizing agent is ammonium persulfate; the pH regulator is sodium hydroxide; the surfactant is sodium lauryl sulfate; the organic additive is citric acid.

[0058] The chemical mechanical polishing solution has a pH of 11.

[0059] The chemical mechanical polishing fluid is obtained by stirring the above-mentioned raw material components evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com