Finishing method for textile with ultraviolet-resisting and antibacterial functions

An anti-ultraviolet and textile technology, applied in the field of textile materials, can solve the problems of high processing conditions, easy exudation, limited application, etc., and achieve the effects of mild reaction conditions, easy degradation, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

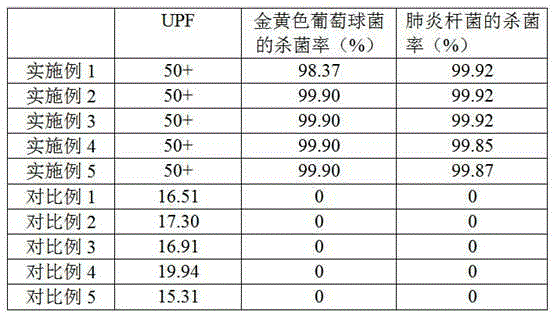

Examples

Embodiment 1

[0051] A method for finishing textiles, the textiles are made of pure cotton, comprising the following steps:

[0052] Step 10): preparing zinc oxide / carboxymethyl chitosan nanocomposite;

[0053] Step 101): Add chitosan to the container, and then add isopropanol solution with a mass fraction of 99.7%, wherein the mass ratio of chitosan and isopropanol solution is 1:8, stir chitosan and isopropanol At the same time as the propanol solution, add a sodium hydroxide solution with a mass fraction of 40%, the mass ratio of chitosan and NaOH solution is 1:2 to form a mixed solution, stir the mixed solution at 44°C, and alkalize the chitosan for 2 hours Afterwards, within 20minh, a chloroacetic acid aqueous solution with a mass fraction of 50% was added dropwise, and the mass ratio of chitosan and chloroacetic acid aqueous solution was 1:3; Methyl chitosan solution, dry and grind to obtain carboxymethyl chitosan;

[0054] Step 102): Mix the carboxymethyl chitosan prepared in step 1...

Embodiment 2

[0061] A method for finishing textiles, the textiles are made of viscose, comprising the following steps:

[0062] Step 10): preparing zinc oxide / carboxymethyl chitosan nanocomposite;

[0063] Step 101): adding chitosan to the container, and then adding isopropanol solution with a mass fraction of 99.7%, wherein the mass ratio of chitosan and isopropanol solution is 1:10, stirring chitosan and isopropanol At the same time as the propanol solution, add a sodium hydroxide solution with a mass fraction of 40%, the mass ratio of chitosan and NaOH solution is 1:1 to form a mixed solution, stir the mixed solution at 44°C, and alkalize the chitosan for 3 hours Afterwards, in 1.5h, the mass fraction of 50% chloroacetic acid aqueous solution was dropped, and the mass ratio of chitosan and chloroacetic acid aqueous solution was 1:1; Carboxymethyl chitosan solution, dry and grind to obtain carboxymethyl chitosan;

[0064] Step 102): Mix the carboxymethyl chitosan prepared in step 101) ...

Embodiment 3

[0071] A method for finishing textiles, the textiles are made of modal, comprising the following steps:

[0072] Step 10): preparing zinc oxide / carboxymethyl chitosan nanocomposite;

[0073] Step 101): adding chitosan to the container, and then adding isopropanol solution with a mass fraction of 99.7%, wherein the mass ratio of chitosan and isopropanol solution is 1:12, stirring chitosan and isopropanol At the same time as the propanol solution, add a sodium hydroxide solution with a mass fraction of 40%, the mass ratio of chitosan and NaOH solution is 1:4 to form a mixed solution, stir the mixed solution at 44°C, and alkalize the chitosan for 4 hours Afterwards, in 1h, the mass fraction is 50% chloroacetic acid aqueous solution, the mass ratio of chitosan and chloroacetic acid aqueous solution is 1: 5; Methyl chitosan solution, dry and grind to obtain carboxymethyl chitosan;

[0074] Step 102): Mix the carboxymethyl chitosan prepared in step 101) with distilled water, and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com