A kind of preparation method of grafted polypropylene non-woven fabric-based ion exchange material

A polypropylene non-woven fabric, ion exchange material technology, applied in chemical instruments and methods, textiles and papermaking, other chemical processes, etc., can solve the problems of difficult large-scale production, high grafting cost, and low grafting rate. , to achieve the effect of fast exchange rate, simple desorption and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Wash the polypropylene non-woven fabric repeatedly with boiling water. After washing, put the sample into a Soxhlet extractor and extract it with acetone for 48 hours. After the extraction is completed, put it in an oven at 80°C and dry it. Add a photosensitizer ethanol solution with a concentration of 1.0wt% into the dish, soak in the dark, and the ethanol will completely volatilize after about 4 hours. Add then in the quartz glass tube that has 30ml acrylic acid (concentration 20.0wt%) solution, after logical nitrogen 10min, irradiate 7h under the ultraviolet light source of 7W, the acrylic acid monomer that remains on its surface with boiling water washing is completed in reaction, and in Extract with acetone in a Soxhlet extractor to wash away short-chain self-polymers, weigh and calculate after drying, and obtain a modified non-woven fabric sample with a grafting rate of 2031.2%.

[0029] Take 0.1g of the grafted sample of this embodiment, add it to 50ml, pH=6, Ce ...

Embodiment 2

[0031] Wash the polypropylene non-woven fabric repeatedly with boiling water. After washing, put the sample into a Soxhlet extractor and extract it with acetone for 48 hours. After the extraction is completed, put it in an oven at 80°C and dry it. Add a photosensitizer ethanol solution with a concentration of 0.5wt% into the dish, soak in the dark, and the ethanol will completely volatilize after about 4 hours. Add then in the quartz glass tube that has 30ml acrylic acid (concentration 17.5wt%) solution, after logical nitrogen 10min, irradiate 7h under the ultraviolet light source of 7W, the acrylic acid monomer that remains on its surface with boiling water washing is completed in reaction, and in Extract with acetone in a Soxhlet extractor to wash away short-chain self-polymers, weigh and calculate after drying, and obtain a modified non-woven fabric sample with a grafting rate of 2551.3%.

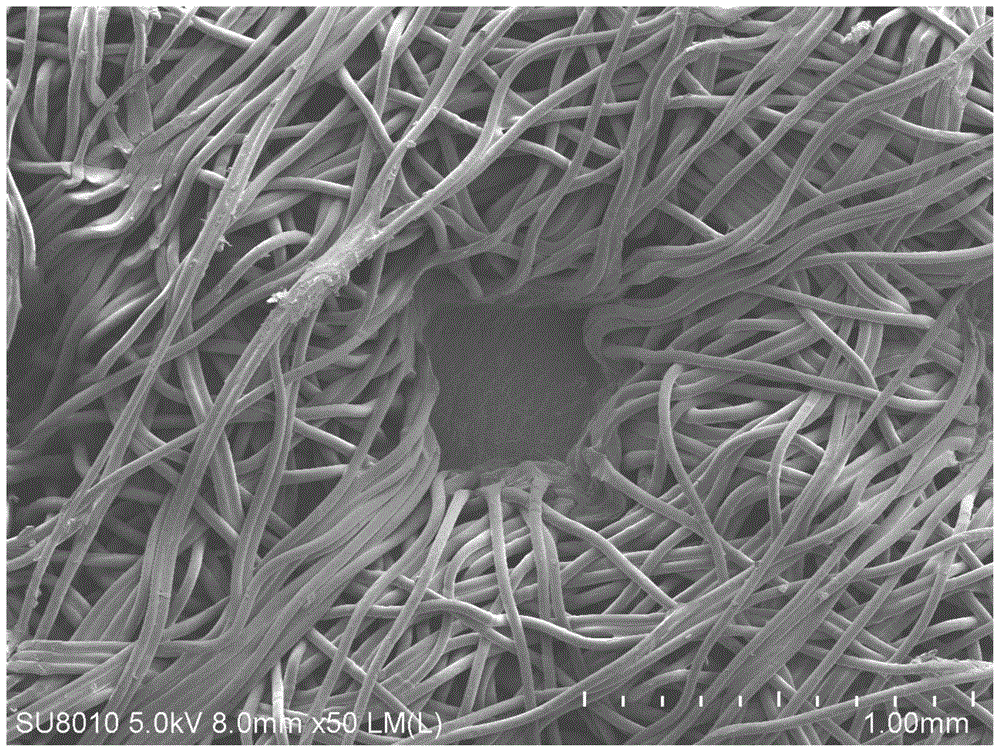

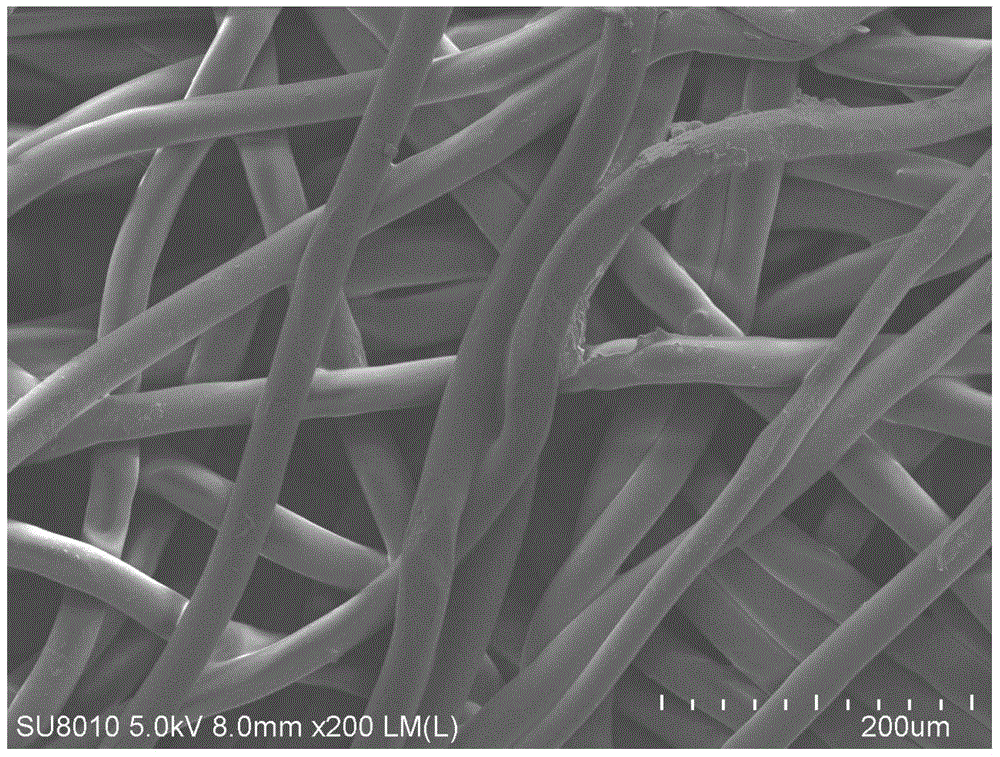

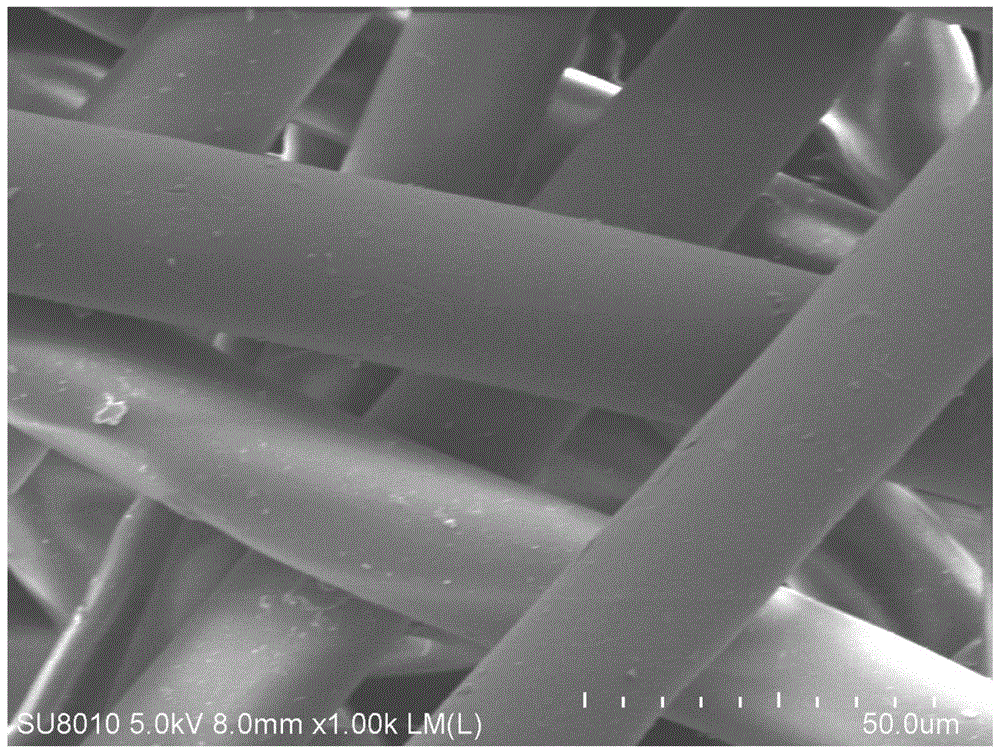

[0032] The scanning electron micrographs of non-woven fabrics with different magnifi...

Embodiment 3

[0038] Wash the polypropylene non-woven fabric repeatedly with boiling water. After washing, put the sample into a Soxhlet extractor and extract it with acetone for 24 hours. After the extraction is completed, put it in an oven at 80°C and dry it. Add a photosensitizer ethanol solution with a concentration of 0.3wt% into the dish, soak in the dark, and the ethanol will completely volatilize after about 4 hours. Add then in the quartz glass tube that has 30ml acrylic acid (concentration 2.5wt%) solution, after logical nitrogen 10min, irradiate 7h under the ultraviolet light source of 7W, the acrylic acid monomer that remains on its surface with boiling water washing is completed after reaction, and in Extract with acetone in a Soxhlet extractor to wash away short-chain self-polymers, weigh and calculate after drying, and a modified non-woven fabric sample with a graft rate of 172.4% can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com