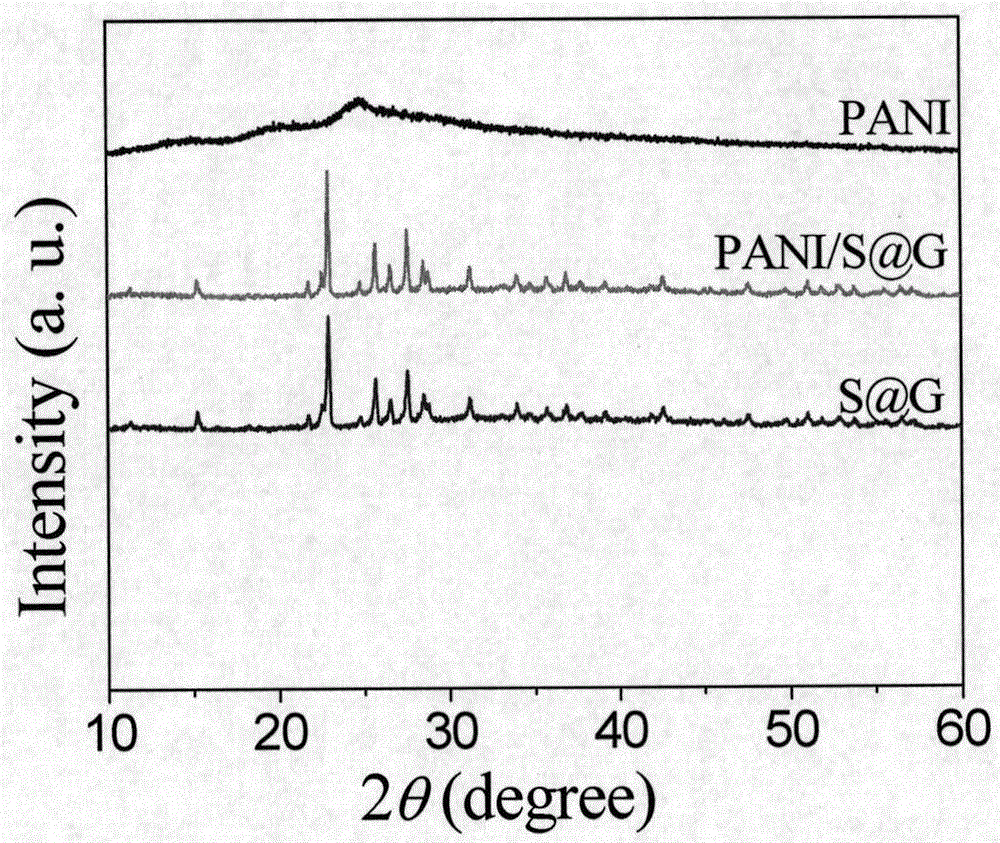

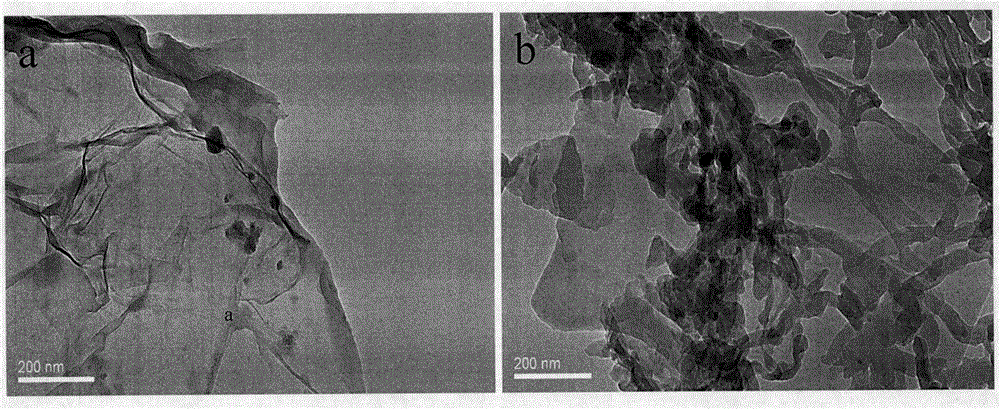

Method for preparing polyaniline/sulfur/graphene composite material

A composite material, graphene technology, applied in electrode manufacturing, electrical components, battery electrodes, etc., can solve the problems of sulfur particle shedding, cycle capacity, attenuation, etc., and achieve the effect of being conducive to industrial production, simple process, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The composition of a polyaniline / sulfur / graphene composite is designed as:

[0027] Polyaniline, 12wt%; Sulfur element, mass fraction 75%; Graphene, mass fraction 13wt%;

[0028] A kind of preparation method of polyaniline / sulfur / graphene composite material: comprise the following steps:

[0029] 1) Weigh 12.4 grams of sodium thiosulfate pentahydrate and mix it with 20 ml of deionized water to configure sodium thiosulfate solution:

[0030] 2) The molar ratio of organic acid to sodium thiosulfate is 1.2, weigh 6 grams of oxalic acid and 0.277 grams of graphene, dissolve in 30 milliliters of tetrahydrofuran, and ultrasonically vibrate for 5 hours;

[0031] 3) Slowly pour the sodium thiosulfate solution in step 1 into the mixed solution in step 2, stir at a constant speed, and reflux at 50° C. for 4 hours;

[0032] 4) Add 0.3 g of aniline to the product of step 3, and stir at a constant speed for 5 h;

[0033] 5) In the product of step 4, pour the initiator, stir, stan...

Embodiment 2

[0036] The composition of a polyaniline / sulfur / graphene composite is designed as:

[0037] Polyaniline, 6wt%; Sulfur element, mass fraction 79%; Graphene, mass fraction 15wt%;

[0038] Polyaniline, 9wt%; Sulfur element, mass fraction 79%; Polyaniline, mass fraction 12wt%;

[0039] Polyaniline, 15wt%; Sulfur element, mass fraction 75%; Polyaniline, mass fraction 10wt%;

[0040] A kind of preparation method of polyaniline / sulfur / graphene composite material: comprise the following steps:

[0041] 1) Weigh a certain amount of sodium thiosulfate pentahydrate and mix it with deionized water to configure sodium thiosulfate solution:

[0042] 2) The molar ratio of organic acid to sodium thiosulfate is 1.3, weigh a certain organic acid, dissolve it in acetone, and oscillate ultrasonically for 10 hours;

[0043] 3) Slowly pour the sodium thiosulfate solution in step 1 into the mixed solution in step 2, stir at a constant speed, and reflux at 60° C. for 5 hours;

[0044] 4) Add anili...

Embodiment 3

[0048] The composition design of a kind of polyaniline / sulfur / graphene composite material is the same as embodiment 1,

[0049] Include the following steps:

[0050] 1) Weigh a certain amount of sodium thiosulfate pentahydrate and mix it with deionized water to configure sodium thiosulfate solution:

[0051] 2) The molar ratio of benzenesulfonic acid to sodium thiosulfate is 1.2, weigh a certain amount of benzenesulfonic acid, dissolve in methyl ethyl ketone, and ultrasonically vibrate for 5 hours;

[0052] 3) Slowly pour the sodium thiosulfate solution in step 1 into the mixed solution in step 2, stir at a constant speed, and reflux at 80° C. for 4 hours;

[0053] 4) Add aniline to the product of step 3, and stir at a constant speed for 10 h;

[0054]5) In the product of step 4, pour the initiator, stir, stand, filter, and dry in vacuum to obtain the polyaniline / sulfur / graphene composite material;

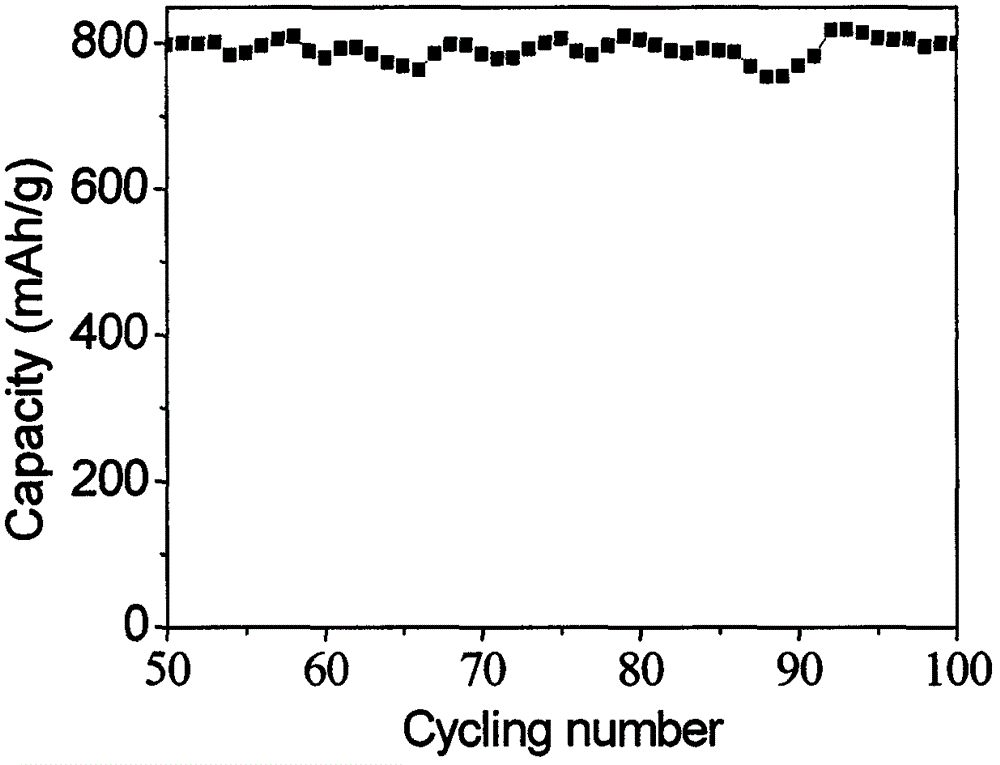

[0055] Preparation and performance test of sulfur electrode; sulfur electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com