Self-assembly material based on silver nanoparticles and preparation method thereof

A technology of silver nanoparticles and self-assembly, applied in the direction of coating, etc., can solve the problems of complex method, cumbersome synthesis method, single structure, etc., and achieve the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1.1 Add 0.0170g of tannic acid into 20ml of secondary water, and dissolve completely to obtain an aqueous solution of tannic acid for later use;

[0031] 1.2 Add potassium carbonate solution (0.1M) dropwise to the above 20ml tannic acid aqueous solution to adjust the pH of the solution to 7.5;

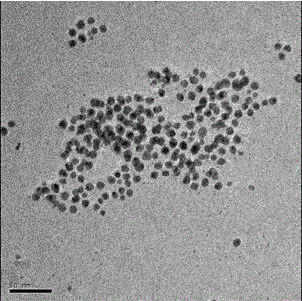

[0032] 1.3 Put the tannic acid aqueous solution with a pH of 7.5 obtained in 1.2 into a water-soluble pot at 30°C to stabilize the temperature at 30°C, then add 0.5ml (0.1M) of silver nitrate aqueous solution dropwise, stir for 60 minutes and then centrifuge to 10ml In the secondary water, a solution containing silver nanoparticles was obtained, and the results are shown in figure 1 ;

[0033] 1.4 Mix 0.5 ml of the aqueous solution containing silver nanoparticles obtained in 1.3 with 4 ml of ethanol solution, then add 0.1 ml of ammonia solution, then add 2 microliters of tetraethyl orthosilicate, stir for 300 minutes, and centrifuge to obtain silver nanoparticles-based self-as...

Embodiment 2

[0036] 2.1 Dissolve 0.0170 g of tannic acid in 20 ml of secondary water, and completely dissolve to obtain an aqueous solution of tannic acid for later use;

[0037] 2.2 Add potassium carbonate solution (0.1M) dropwise to the above 20ml tannic acid aqueous solution to adjust the pH of the solution to 7.5;

[0038] 2.3 Put the tannic acid aqueous solution with a pH of 7.5 obtained in Example 1.2 into a water-dissolving pot at 30°C to stabilize the temperature at the temperature of the water bath, then add 0.5 ml (0.1M) of silver nitrate aqueous solution dropwise, stir for 60 minutes, and then centrifuge Separation into 10 ml of secondary water;

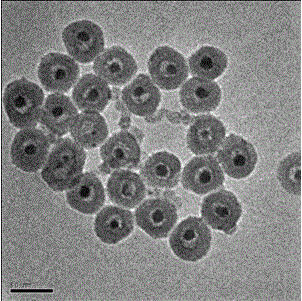

[0039] 2.4 Mix 0.5 ml of silver solution obtained in 2.3 with 4 ml of ethanol solution, then add 2 microliters of tetraethyl orthosilicate, stir for 20 minutes, the color changes from yellow to orange red, then add 0.1 ml of ammonia solution, and stir for 5 hours Self-assembled materials based on silver nanoparticles (a composite stru...

Embodiment 3

[0042] 3.1 Dissolve 0.0170 g of tannic acid into 20 ml of secondary water, and completely dissolve to obtain an aqueous solution of tannic acid for later use;

[0043] 3.2 Add potassium carbonate solution (0.1M) dropwise to the above 20ml tannic acid aqueous solution to adjust the pH of the solution to 6.5;

[0044] 3.3 Put the tannic acid aqueous solution with a pH of 6.5 obtained in 3.2 into a water-dissolving pot at 30°C to stabilize the temperature at the temperature of the water bath, then add 0.5 ml (0.1M) of silver nitrate aqueous solution dropwise, stir for 400 minutes, and centrifuge to In 10 milliliters of secondary water, an aqueous solution containing silver nanoparticles is obtained;

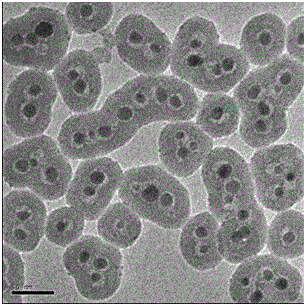

[0045] 3.4 Mix 0.5 ml of the aqueous solution containing silver nanoparticles obtained in 3.3 with 4 ml of ethanol solution, then add 0.1 ml of ammonia solution, then add 2 microliters of tetraethyl orthosilicate, stir for 300 min and centrifuge to obtain silver nanoparticle-based ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com