Eddy-current hole surface barrel grinding and finishing processing device and processing method thereof

A processing device and finishing technology, which is applied to surface polishing machine tools, metal processing equipment, grinding/polishing equipment, etc. Realize the effect of automation, small footprint and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

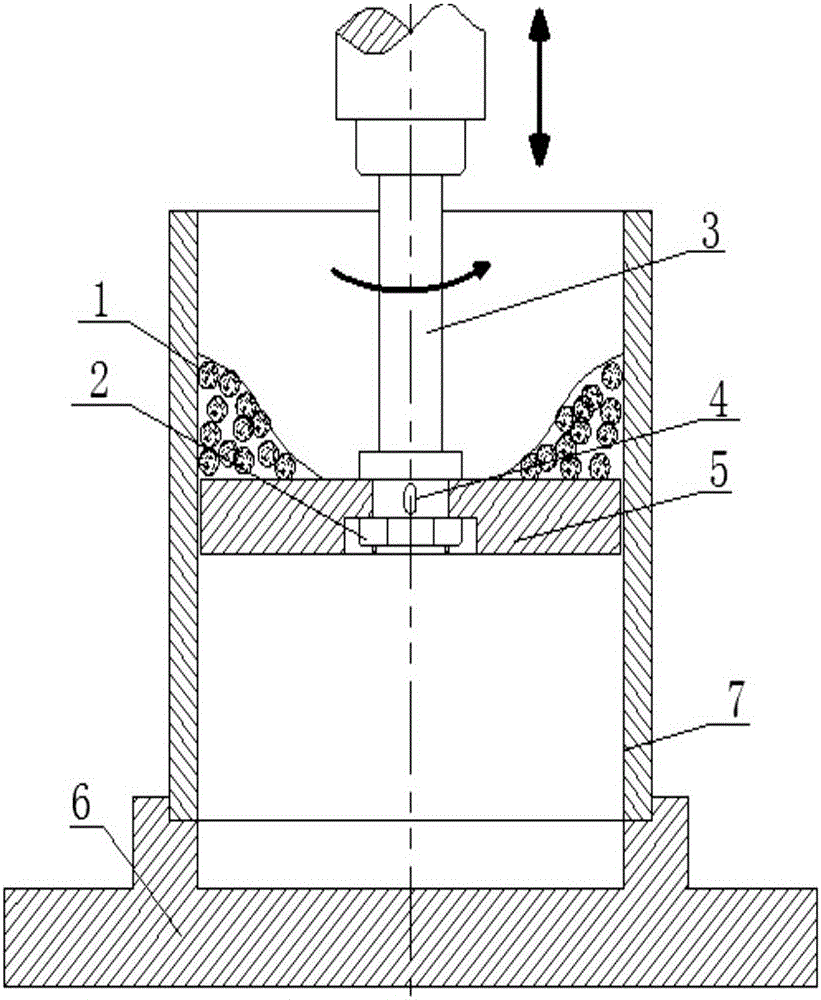

[0013] The vortex-type hole surface barrel finishing processing device, the outer diameter of the centrifugal disc 5 is Φ148mm, the material of the spherical abrasive 1 is aluminum oxide, the diameter is 5mm, the workpiece is a seamless steel pipe of grade 45, and the specification is Φ150×10mm. The hole surface roughness value is Ra2.935μm, and the specific processing steps are as follows:

[0014] 1. Put the workpiece on the workbench, put the flexible smooth head into the hole to be processed.

[0015] 2. Turn on the power, turn on the governor, and set the speed value of the centrifugal disc 5 to 400r / min through the governor.

[0016] 3. Start the flexible finishing head, the centrifugal disk 5 starts to rotate and drives the spherical abrasive to process the surface of the hole.

[0017] 4. After processing for 10 minutes, take out the device.

[0018] After testing, the surface roughness of the hole can reach Ra0.427μm.

Embodiment approach 2

[0020] The vortex-type hole surface rolling and finishing processing device, the outer diameter of the centrifugal disc 5 is Φ148mm, the material of the spherical abrasive 1 is aluminum oxide, the diameter is 8mm, the workpiece is a seamless steel pipe of grade 45, and the specification is Φ150×10mm. The hole surface roughness value is Ra2.935μm,

[0021] The steps of its specific concrete processing method are:

[0022] 1. Put the workpiece on the workbench, put the flexible smooth head into the hole to be processed.

[0023] 2. Turn on the power, turn on the governor, and set the speed value of the centrifugal disc 5 to 600r / min through the governor.

[0024] 3. Start the flexible smoothing head, the centrifugal disc 5 starts to rotate and drives the spherical abrasive to process the surface of the hole.

[0025] 4. After processing for 10 minutes, take out the device.

[0026] After testing, the surface roughness of the hole can reach Ra0.487μm.

Embodiment approach 3

[0028] The vortex type hole surface rolling and finishing processing device, the outer diameter of the centrifugal disc 5 is Φ148mm, the material of the spherical abrasive 1 is aluminum oxide, the diameter is 10mm, and the workpiece is a seamless steel pipe of grade 45 with a specification of Φ150×10mm. The hole before processing The surface roughness value is Ra2.935μm, and the specific processing steps are as follows:

[0029] 1. Put the workpiece on the workbench, put the flexible smooth head into the hole to be processed.

[0030] 2. Turn on the power, turn on the governor, and set the speed value of the centrifugal disc 5 to 800r / min through the governor.

[0031] 3. Start the flexible finishing device, the centrifugal disk 5 starts to rotate and drives the spherical abrasive to process the surface of the hole.

[0032] 4. After processing for 10 minutes, take out the device.

[0033] The hole surface roughness value after testing and processing can reach Ra0.587μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com