Preparation method of core-shell type highly dielectric filler from barium titanate-doped multi-walled carbon nanotubes

A technology of multi-walled carbon nanotubes and barium titanate, which is applied in chemical instruments and methods, titanium compounds, inorganic chemistry, etc., can solve the problems of weak effect, inability to obtain a coating layer, and inability to continuously coat a layer, and achieve operational The effect of simplicity, high output and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment changes the type of surfactant on the basis of Comparative Example 2.

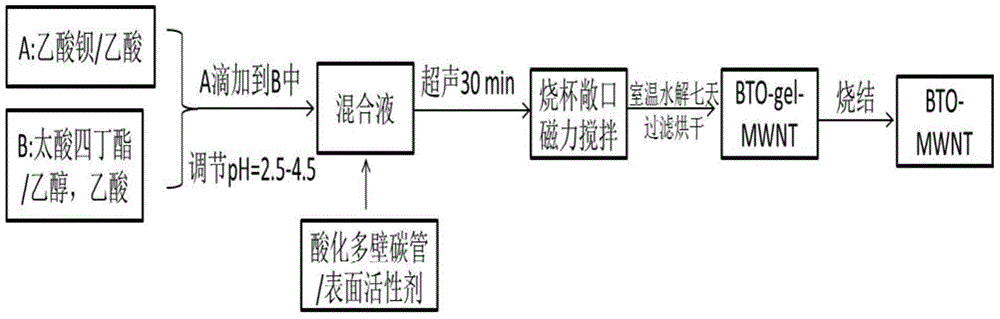

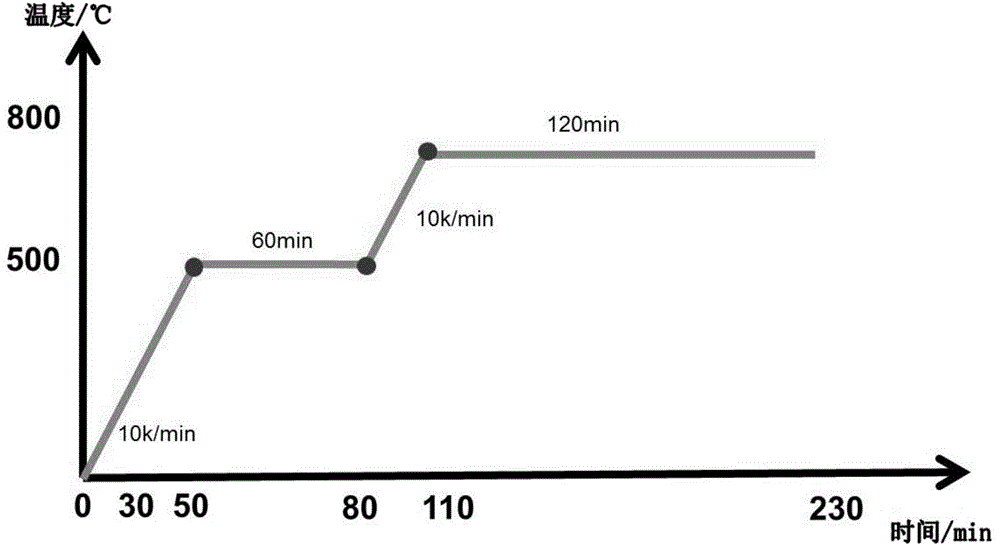

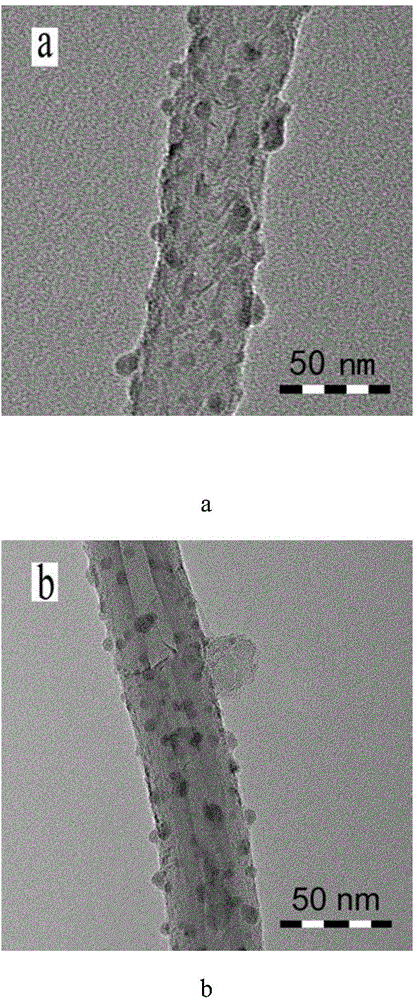

[0035] Pour 100ml of acetic acid into a 250ml three-neck flask, move it into an oil bath and heat it to 80°C, add 6.38g of barium acetate under the action of magnetic stirring, take it out of the oil bath and cool it to room temperature after it is completely dissolved, record it as Solution A: Add 75ml of acetic acid to a 250ml beaker, add 8.51g of tetrabutyl titanate and then add 25ml of ethanol, mix evenly, record it as solution B, and directly drop solution A that has been cooled to room temperature into the In the beaker of solution B, after mixing evenly, use acetic acid and ethanol to adjust the pH value to make pH=3. 1 g of acidified multi-walled carbon nanotubes (carboxyl content: 1.23-2.00 wt% CNT605 Beijing Deke Daojin Technology Co., Ltd.) and 0.2 g of SDBS were added to the above mixed solution for ultrasonic dispersion for 30 min. Afterwards, the dispersion system was ...

Embodiment 2

[0037] Pour 100ml of acetic acid into a 250ml three-neck flask, move it into an oil bath and heat it to 80°C, add 6.38g of barium acetate under the action of magnetic stirring, take it out of the oil bath and cool it to room temperature after it is completely dissolved, record it as Solution A: Add 75ml of acetic acid to a 250ml beaker, add 8.51g of tetrabutyl titanate and then add 25ml of ethanol, mix evenly, record it as solution B, and directly drop solution A that has been cooled to room temperature into the In the beaker of solution B, after mixing evenly, use acetic acid and ethanol to adjust the pH value to make pH=4. Add 1 g of acidified multi-walled carbon nanotubes (carboxyl content: 1.23-2.00 wt % CNT605 Beijing Deke Daojin Technology Co., Ltd.) and 0.4 g of SDBS to the above mixed solution for ultrasonic dispersion for 30 min. Afterwards, the dispersion system was hydrolyzed at room temperature for seven days at a stirring rate of 150 r / min, filtered and vacuum-dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com