Plant starch-chitosan composite packaging film and preparation method thereof

A technology of plant starch and packaging film, applied in the field of packaging film, can solve problems such as non-recyclability, achieve good physical and mechanical properties, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

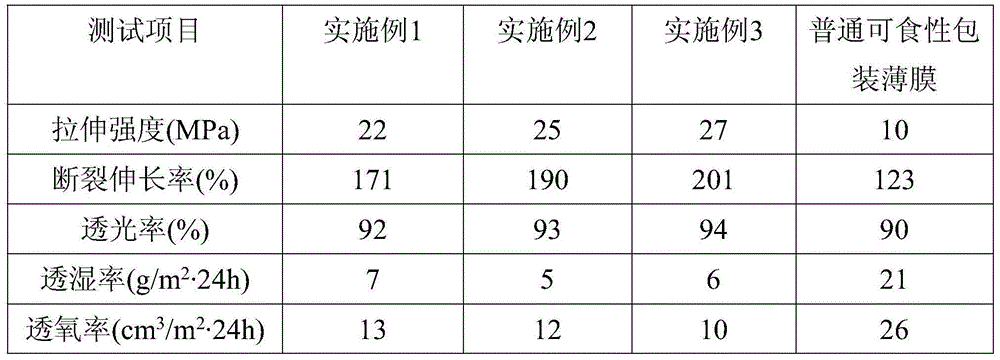

Examples

Embodiment 1

[0019] A plant starch-chitosan composite packaging film, which is made of the following mass parts of raw materials:

[0020] 90 parts of corn starch, 50 parts of chitosan, 25 parts of Coptis, 20 parts of rosemary, 15 parts of konjac powder, 15 parts of sodium alginate, 12 parts of polyvinyl alcohol, 12 parts of epoxy soybean oil, low methoxyl group 10 parts of pectin, 8 parts of calcium citrate, 8 parts of coagulated polysaccharides, 6 parts of edible gelatin, 5 parts of genipin, 4 parts of polyglycerin fatty acid esters, 3 parts of food flavors, and 1000 parts of water.

[0021] According to the above formula, prepare the plant starch-chitosan composite packaging film, and the specific steps are as follows:

[0022] (1) Add plant starch to water in batches under stirring, mix evenly to form a starch slurry, then adjust the pH value to 6-7 with a 3-5% sodium carbonate aqueous solution, and then heat to 60-80℃ and stir. 20-30min to form a uniform paste solution;

[0023] (2) Slowly a...

Embodiment 2

[0028] A plant starch-chitosan composite packaging film, which is made of the following mass parts of raw materials:

[0029] 95 parts of corn starch, 55 parts of chitosan, 28 parts of Coptis, 23 parts of rosemary, 18 parts of konjac powder, 16 parts of sodium alginate, 14 parts of polyvinyl alcohol, 13 parts of epoxy soybean oil, low methoxyl group 11 parts of pectin, 9 parts of calcium citrate, 9 parts of coagulated polysaccharides, 8 parts of edible gelatin, 6 parts of genipin, 5 parts of polyglycerol fatty acid esters, 4 parts of food flavors, and 1100 parts of water.

[0030] The preparation method of the plant starch-chitosan composite packaging film in this example is the same as that in Example 1.

Embodiment 3

[0032] A plant starch-chitosan composite packaging film, which is made of the following mass parts of raw materials:

[0033] 100 parts of corn starch, 60 parts of chitosan, 30 parts of Coptis, 25 parts of rosemary, 20 parts of konjac flour, 18 parts of sodium alginate, 15 parts of polyvinyl alcohol, 15 parts of epoxy soybean oil, low methoxyl group 12 parts of pectin, 10 parts of calcium citrate, 10 parts of coagulated polysaccharides, 9 parts of edible gelatin, 8 parts of genipin, 6 parts of polyglycerol fatty acid esters, 5 parts of food flavors, 1200 parts of water.

[0034] The preparation method of the plant starch-chitosan composite packaging film in this example is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com