A kind of preparation method of environment-friendly flame retardant silk fabric

A silk and fabric technology, applied in textiles and papermaking, fiber treatment, physical treatment, etc., can solve the problems of poisonous dioxin, water resistance needs to be improved, etc., and achieve the effect of low cost, good antibacterial and antibacterial, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

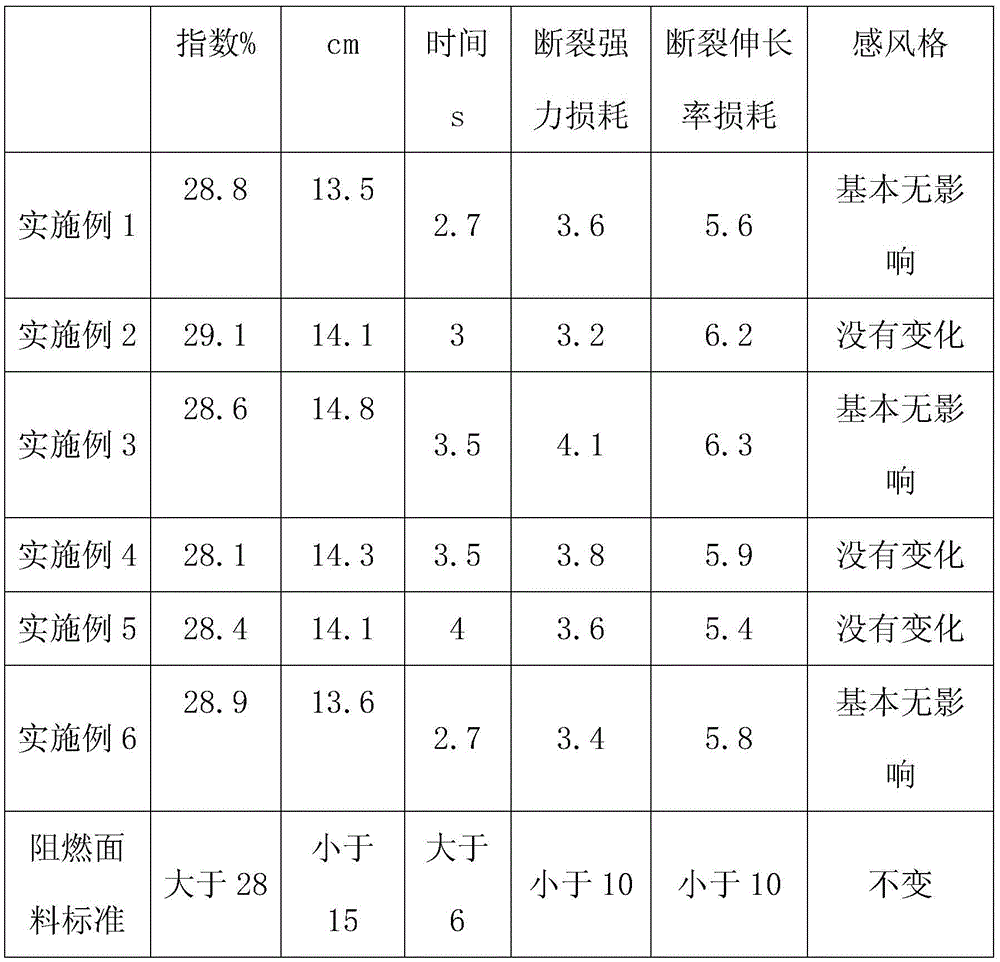

Examples

Embodiment 1

[0017] Chitosan is modified by atom transfer radical technology to obtain chitosan derivative chitosan methacrylate with an average molecular weight of 38000Da and a particle size of 120-180nm, and chitosan methacrylate is made into a concentration A 60% solution of modified chitosan derivatives. After removing surface impurities and activating the surface of the silk fabric, soaking in the modified chitosan derivative solution for 10 minutes, taking out the water, washing and drying to obtain the pretreated silk fabric.

[0018] Microwave the pretreated silk fabric for 10 minutes at a power of 500W to polymerize the chitosan derivatives on the surface of the silk. After reaching an average degree of polymerization of 12, wash with ethanol, wash with water, dry at 50°C, and dry at 150°C. Dry down for 3 seconds to obtain a flame-retardant silk fabric.

Embodiment 2

[0020] Chitosan is modified by atom transfer radical technology to obtain chitosan derivative chitosan methacrylate with an average molecular weight of 38000Da and a particle size of 120-180nm, and chitosan methacrylate is made into a concentration A 70% solution of modified chitosan derivatives. After removing surface impurities and activating the surface of the silk fabric, soaking in the modified chitosan derivative solution for 20 minutes, taking out the water, washing and drying to obtain the pretreated silk fabric.

[0021] Microwave the pretreated silk fabric for 5 minutes at a power of 600W to polymerize the chitosan derivatives on the surface of the silk. After reaching an average degree of polymerization of 17, wash with ethanol, wash with water, dry at 60°C, and dry at 150°C. Dry down for 5 seconds to obtain a flame retardant silk fabric.

Embodiment 3

[0023] Chitosan is modified by atom transfer radical technology to obtain chitosan derivative chitosan methacrylate with an average molecular weight of 38000Da and a particle size of 120-180nm, and chitosan methacrylate is made into a concentration A 65% solution of a modified chitosan derivative. After removing surface impurities and surface activation of the silk fabric, soaking in the modified chitosan derivative solution for 15 minutes, taking out the water, washing and drying to obtain the pretreated silk fabric.

[0024] Microwave the pretreated silk fabric for 8 minutes at a power of 550W to polymerize chitosan derivatives on the surface of the silk. After reaching an average degree of polymerization of 12-17, wash with ethanol, wash with water, and dry at 55°C. Dry setting at 150°C for 4s to obtain a flame-retardant silk fabric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com