Novel secondary battery cathode sulfur and selenium binary material and preparation method

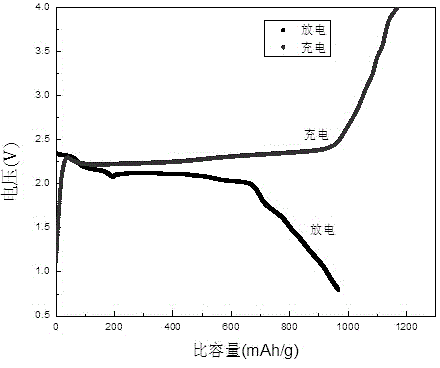

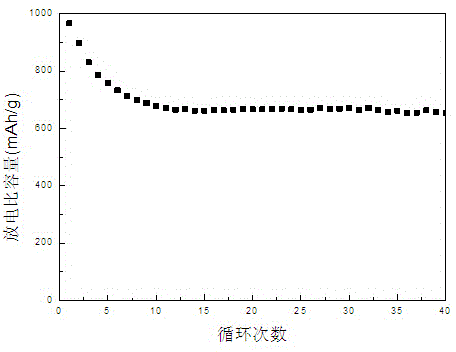

A secondary battery and binary material technology, applied in the field of electrochemical batteries, can solve the problems of low utilization rate of sulfur cathode and poor cycle performance, and achieve good active material utilization rate, high specific capacity, and good cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

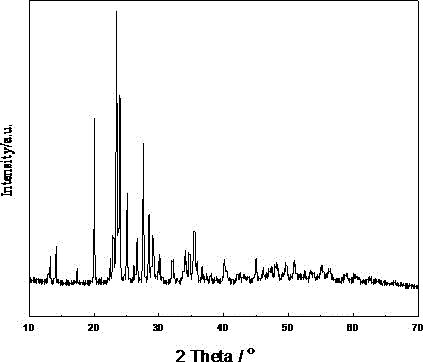

[0031] Weigh 1.5g of selenium powder and 2.5g of sublimed sulfur respectively, mill them on a ball mill at a speed of 400r / min for 4h, then put them into a closed container, and carry out the sealing operation in a glove box filled with argon. Take out the closed container and put it in a muffle furnace for melting heat treatment: ① heat preservation at 150 °C for 1 hour; ② heat preservation at 230 °C for 1 hour; ③ heat preservation at 300 °C for 2 hours. During the heating process, it is guaranteed to shake several times to ensure the uniformity of the molten state. Finally, put it into ice water for rapid cooling to obtain the binary product. figure 1 is the resulting binary material Se 3 S 5 The XRD pattern is basically the same as the standard PDF card. Press Se 3 S 5 : Ketjen black=7:3 mass ratio mixed ball milling, and then heated at 160°C for 12 hours under argon protection in a tubular atmosphere furnace to obtain Se 3 S 5 / C Composite. Using N-methylpyrrolidon...

Embodiment 2

[0033]Weigh 1.0g of selenium powder and 2.0g of sublimed sulfur respectively, ball mill for 3h at a speed of 500r / min in a ball mill, then put them into a closed container, and carry out sealing operation in a glove box filled with argon. Take out the airtight container and put it in a muffle furnace for melting heat treatment: ① heat preservation at 160 °C for 0.5 hours; ② heat preservation at 250 °C for 2 hours; ③ heat preservation at 300 °C for 1 hour. During the heating process, it is guaranteed to shake several times to ensure the uniformity of the molten state. Finally, quickly put it into ice water for rapid cooling to obtain the product binary material SeS 2 . Press SeS 2 : Graphene = 3:1 mass ratio mixed ball mill, and then heated at 165°C for 10 hours in a tubular atmosphere furnace under the protection of nitrogen to obtain SeS 2 / C Composite. Using deionized water as solvent, the prepared SeS 2 / C composite material, Ketjen black and LA133 were mixed at a mass...

Embodiment 3

[0035] Weigh 2.5g of selenium powder and 1.5g of sublimed sulfur respectively, ball mill on a ball mill at a speed of 300r / min for 6h, then put the mixture into a closed container, and carry out the sealing operation in a glove box filled with argon. Take out the airtight container and put it in a muffle furnace for melting heat treatment: ① heat preservation at 149 °C for 1 hour; ② heat preservation at 230 °C for 1 hour; ③ heat preservation at 280 °C for 3 hours. During the heating process, it is guaranteed to shake several times to ensure the uniformity of the molten state. Finally, quickly put it into ice water for rapid cooling to obtain the product binary material Se 5 S 3 . Press Se 5 S 3 : carbon nanotubes = 3:2 mass ratio mixed ball milling, and then heated at 160°C for 8 hours under the protection of argon in a tubular atmosphere furnace to obtain Se 5 S 3 / C Composite. Using N-methylpyrrolidone as an organic solvent, the prepared Se 5 S 3 / C composite materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com