Fenofibric acid crystal form and preparation method thereof

A fenofibric acid and crystal form technology, applied in the field of medicine, achieves the effects of low impurity content, good reproducibility, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

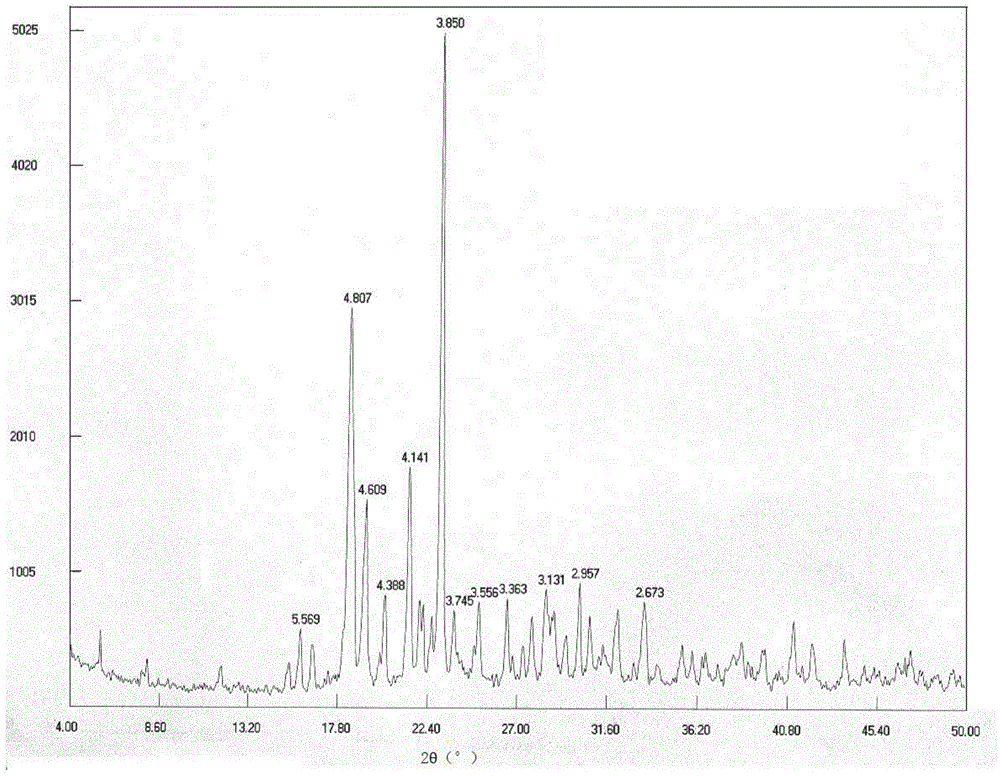

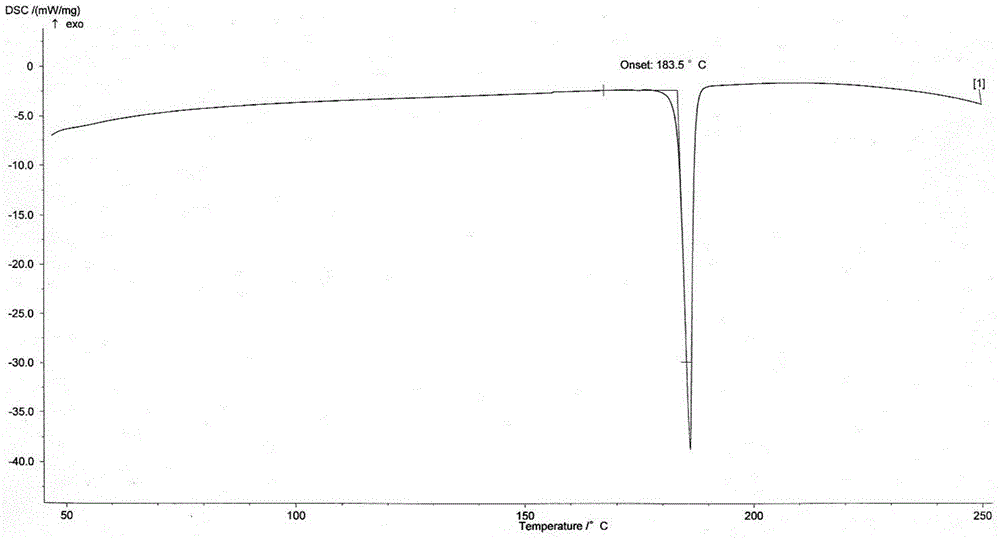

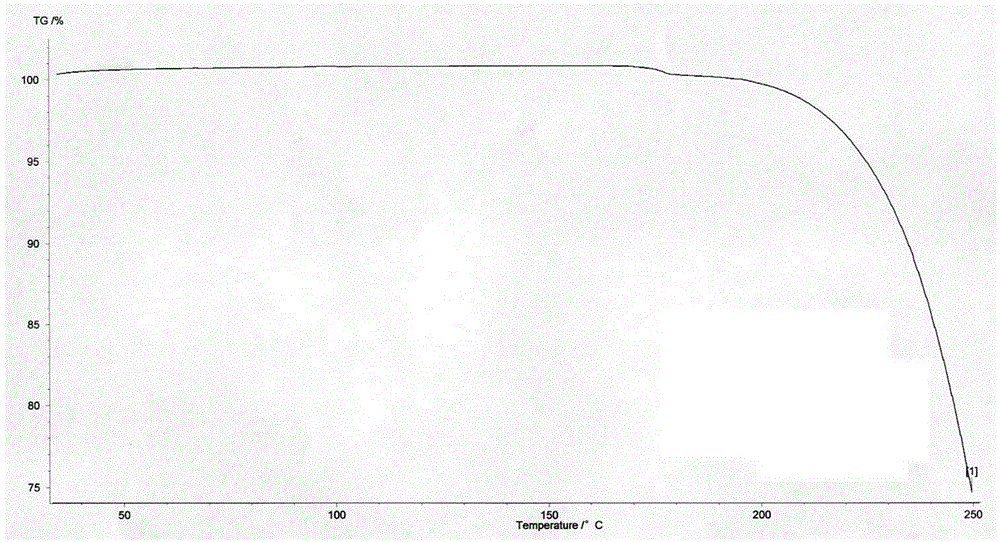

[0020] Get the fenofibric acid crude product (Wuhan Hongxinkang Fine Co., Ltd.) 10.0g of light yellow powder, and the isopropanol of 100mL is placed in the round bottom flask of 250mL, heats in oil bath, the setting of oil bath The temperature is 95°C, after heating to reflux, add 1.0 g of activated carbon, and continue to reflux for 10 minutes. Use a Buchner funnel to vacuum filter while it is hot. The filtrate is cooled to crystallize at room temperature, and the Buchner funnel is vacuum filtered. The filter cake is washed once with 10 mL of isopropanol. After washing, the product is vacuum-dried at 80 ° C for 12 hours to obtain a white The powdered crystals are 8.6 g of fenofibric acid, and the fenofibric acid obtained in this example was detected by X-ray powder diffraction.

[0021] Test instrument: Swiss x’TRA X-ray diffractometer;

[0022] Test conditions: 40kv 40mA;

[0023] slit:2 / 4 / 0.5 / 0.2;

[0024] step: 0.02DEG;

[0025] Target type: Cu;

[0026] Range: 7.00-4...

Embodiment 2

[0035] Get fenofibric acid crude product (Wuhan Hongxinkang Fine Co., Ltd.) 10.0g, and 100mL of isopropanol (analytical pure) is placed in a 250mL round bottom flask, heated in an oil bath, and the temperature set by the oil bath is After heating to reflux, add 1.0g of activated carbon, continue to reflux for 10min, and vacuum filter with a Buchner funnel while it is hot. Once, after washing, the product was vacuum-dried at 80°C for 12 hours to obtain a white powdery crystal, which was fenofibric acid, weighing 8.6g, and the crystal was detected by X-ray powder diffraction method, and the detection parameters and implementation Example 1 is the same, and the gained XRD pattern is as follows Image 6 As shown, in terms of 2θ angle and interplanar spacing (d value), it is expressed at 15.920 (5.562), 18.440 (4.807), 19.240 (4.609), 20.220 (4.388), 21.440 (4.141), 23.100 (3.847), 23.760 (3.742) , 25.060 (3.550), 26.480 (3.363), 28.420 (3.138), 30.180 (2.959), 32.120 (2.784), wit...

Embodiment 3

[0038] Example 3 Stability detection of fenofibric acid crystal form

[0039] The fenofibric acid obtained in Example 1 is placed in the following environment, and the light intensity is 4500lx ± 500lx, and the obtained results are shown in Table 1-3:

[0040] Table 1 Investigation results of stability test under strong light irradiation

[0041]

[0042] Table 2 High temperature test stability test results (60±2°C)

[0043]

[0044] Table 3 High humidity test stability test results (RH90±5%)

[0045]

[0046] It can be seen from Table 1-3 that the fenofibrate acid crystal form of the present invention has no change in related substances, the appearance and color of the fenofibrate acid crystal form of the present invention under the conditions of strong light, high temperature and high humidity, and the content of fenofibric acid does not change. Changes occur, indicating that the crystal form obtained by the method of the present invention has good stability and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com