Early-strengthening polycarboxylate water reducer and preparation method thereof

A polycarboxylic acid and early-strength type technology, which is applied in the field of early-strength polycarboxylate water reducer and its preparation, can solve problems such as difficult molecular weight, product performance decline, and building structure damage, and achieve good steric hindrance effect, Accelerates cement hydration and has good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

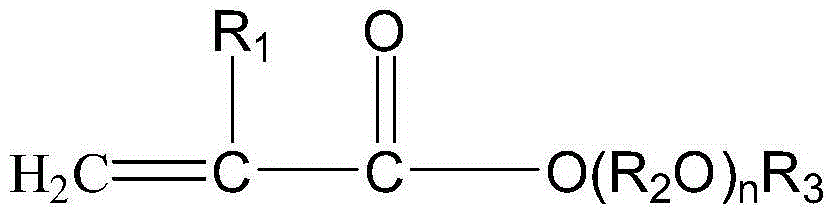

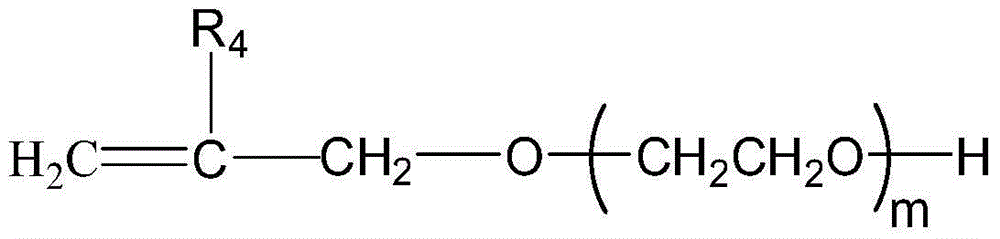

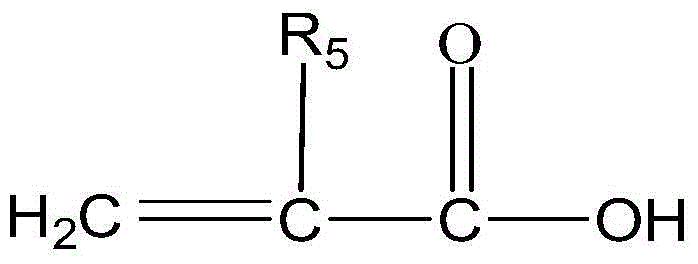

[0042] The preparation method of the early-strength polycarboxylate water reducer includes adding the four monomers, initiators and chain transfer agents into a solvent, and preparing the copolymer through solution polymerization.

[0043] In one embodiment of the present invention, the solvent is water; temperature is the most critical step in the polymerization reaction and plays an important role in the chain initiation reaction. When the temperature is low, the polymerization reaction is difficult to carry out, and if the temperature is too high, side reactions are likely to occur. The temperature selected in the present invention is between 60° C. and 80° C., and the formation of reaction products can be better controlled within this range.

[0044] Whether the polycarboxylate superplasticizer structure copolymerizes well is related to the feeding method. The polymerization method is one of the important factors affecting the uniformity of the product structure. Different...

Embodiment 1

[0053] In the reactor, add 190 grams of water and 270 grams of monomer A (methoxy polyethylene glycol acrylate, n=52), 40.5 grams of monomer B (allyl polyoxyethylene ether, m=28), 10.13 grams of monomer D (2-acrylamido-2 methylpropanesulfonic acid), stirring and heating to 65 ° C, after the above three monomers are dissolved, add 16.88 grams of monomer C (acrylic acid), and then add the initiator dropwise (the mixture of 3.38 grams of ammonium persulfate and 40 grams of water), chain transfer agent (the mixture of 0.68 grams of mercaptoacetic acid and 68 grams of water), was added dropwise at a uniform speed for 4 hours respectively, and the aging time was 2 hours. After the reaction finished, the temperature of the system was lowered to normal temperature, adjust the pH value of the reaction mixture to neutrality with a NaOH aqueous solution with a mass concentration of 30%, and discharge the material to obtain the high-performance polycarboxylate water reducer product ZPC-1. ...

Embodiment 2

[0055] In the reactor, add 190 grams of water and 236.3 grams of monomer A (methoxypolyethylene glycol acrylate, n=30), 60.75 grams of monomer B (methallyl polyoxyethylene ether, m=28 ), 10.13 grams of monomer D (2-acrylamido-2 methylpropanesulfonic acid), stirred and heated to 60 ° C, after the above three monomers were dissolved, 30.39 grams of monomer C (acrylic acid) was added, and then added dropwise to trigger Agent (4.05 grams of ammonium persulfate and 48 grams of water mixture), chain transfer agent (1.01 grams of mercaptoacetic acid and 50.5 grams of water mixture), was added dropwise at a constant speed for 3 hours respectively, and the aging time was 2 hours. After the reaction, the temperature of the system was reduced to At room temperature, adjust the pH value of the reaction mixture to neutral with a NaOH aqueous solution with a mass concentration of 30%, and discharge the material to obtain the high-performance polycarboxylate water reducer product ZPC-2. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com