Flexible transparent conductive thin film and preparation method thereof

A transparent conductive film, flexible technology, applied in cable/conductor manufacturing, conductive layer on insulating carrier, conductive material dispersed in non-conductive inorganic material, etc., can solve the problem of poor light transmittance, poor conductivity, disadvantageous large size Chemical device preparation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

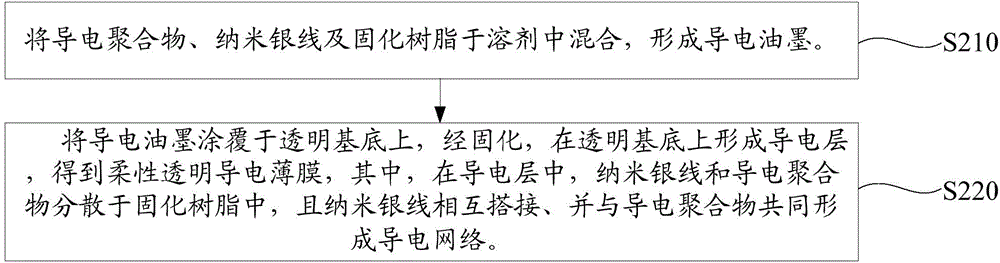

[0045] like figure 2 As shown, the method for preparing a flexible transparent conductive film according to one embodiment can be used to prepare the above-mentioned flexible transparent conductive film. The preparation method of the flexible transparent conductive film comprises the following steps:

[0046] Step S210: Mix the conductive polymer, silver nanowires and cured resin in a solvent to form a conductive ink.

[0047] Wherein, the mass percentage of the conductive polymer, the nano-silver wire and the cured resin is 3-10:5-50:18-25. More preferably, the mass percentage of the conductive polymer, the nano-silver wire and the cured resin is 5:18:23.

[0048] The conductive polymer is selected from polypyrrole, derivatives of polypyrrole, polythiophene, derivatives of polythiophene, polyaniline, derivatives of polyaniline, polyacetylene, derivatives of polyacetylene, and polystyrenesulfonic acid. A sort of.

[0049] Among them, the derivatives of polypyrrole are pol...

Embodiment 1

[0072] The preparation steps of the flexible transparent conductive film of the present embodiment are as follows:

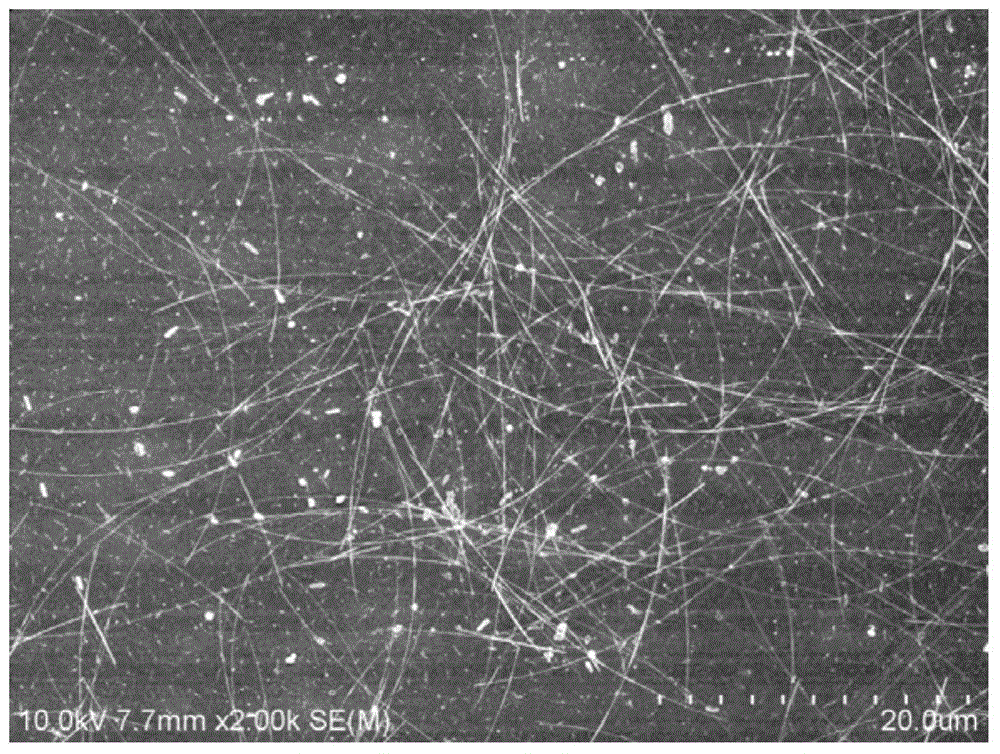

[0073] (1) Place the conductive polymer, cured resin, solvent, plasticizer, coupling agent, defoamer and surfactant in a high-speed mixer and mix them. After mixing evenly, add nano-silver wires and continue to mix and mix. Dispersed to form conductive ink, wherein the mass percentage of conductive polymer, nano-silver wire and cured resin is 5:16:20, the conductive polymer is poly 3,4-ethyldioxypyrrole, and the cured resin is bisphenol A Epoxy resin and F-51 novolac epoxy resin, the diameter of the nano-silver wire is 20-65 nanometers, and the length is 10-30 microns; the solvent is butyl glycidic acid and dibutyl phthalate, and the solvent and the curing resin The mass percent of plasticizer is dioctyl phthalate, and the mass percent of plasticizer and cured resin is 1:18; Coupling agent is butyl titanate, and the ratio of coupling agent and cured resin The m...

Embodiment 2

[0080] The preparation steps of the flexible transparent conductive film of the present embodiment are as follows:

[0081] (1) Place the conductive polymer, cured resin, solvent, plasticizer, coupling agent, defoamer and surfactant in a high-speed mixer and mix them. After mixing evenly, add nano-silver wires and continue to mix and mix. Disperse to form conductive ink, wherein, the mass percentage of conductive polymer, nano-silver wire and cured resin is 5:18:23, and the conductive polymer is poly-m-methoxyaniline and poly(3-lactyl)pyrrole-[2 , 5-bis(p-nitrobenzene)], the cured resin is polyurethane resin (purchased from Xianyang Jingxin Huiming Chemical Co., Ltd.), the diameter of the nano-silver wire is 12~45 nanometers, and the length is 25~40 microns; Solvent is N-vinylpyrrolidone and glycerin, and the mass percent of solvent and cured resin is 2.5:1; Plasticizer is diisooctyl phthalate, and the mass percent of plasticizer and cured resin is 0.8:23; The coupling agent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com