Modified composite diaphragm and method for preparing diaphragm

A composite modification and diaphragm technology, applied in chemical instruments and methods, synthetic resin layered products, electrical components, etc., can solve the problems of unfavorable high-rate discharge performance of batteries, high air permeability of diaphragms, and high preparation costs, and achieve easy The effect of industrialized production, low air permeability value and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Specifically, the preparation method of the composite modified diaphragm according to the embodiment of the present invention includes the following steps:

[0032] A), the thickener is dissolved in deionized water to form an aqueous solution;

[0033] B), ceramics and polyvinylidene fluoride-hexafluoropropylene are dispersed in an aqueous solution to form a suspension;

[0034] C) A binder is added to the suspension to form a slurry. In the slurry, deionized water accounts for 50-80 wt%, ceramics accounts for 20-60 wt%, and polyvinylidene fluoride-hexafluoropropylene accounts for 20-60 wt%. , the binder accounts for 1.5-8wt%, and the thickener accounts for 0.3-0.8wt%;

[0035] D), the slurry is evenly coated on at least one surface of the film substrate;

[0036] E), drying the film substrate coated with the slurry to obtain a composite modified diaphragm;

[0037] Wherein, the ceramic is selected from one or more of alumina, zirconia and titania with a particle dia...

specific Embodiment 1

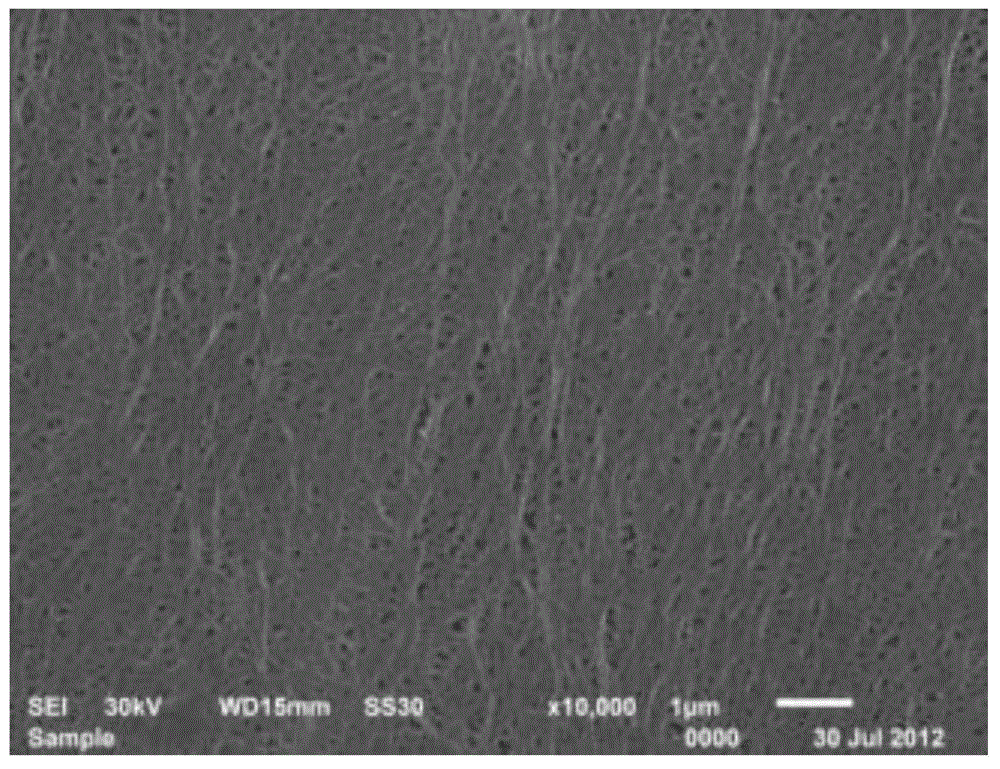

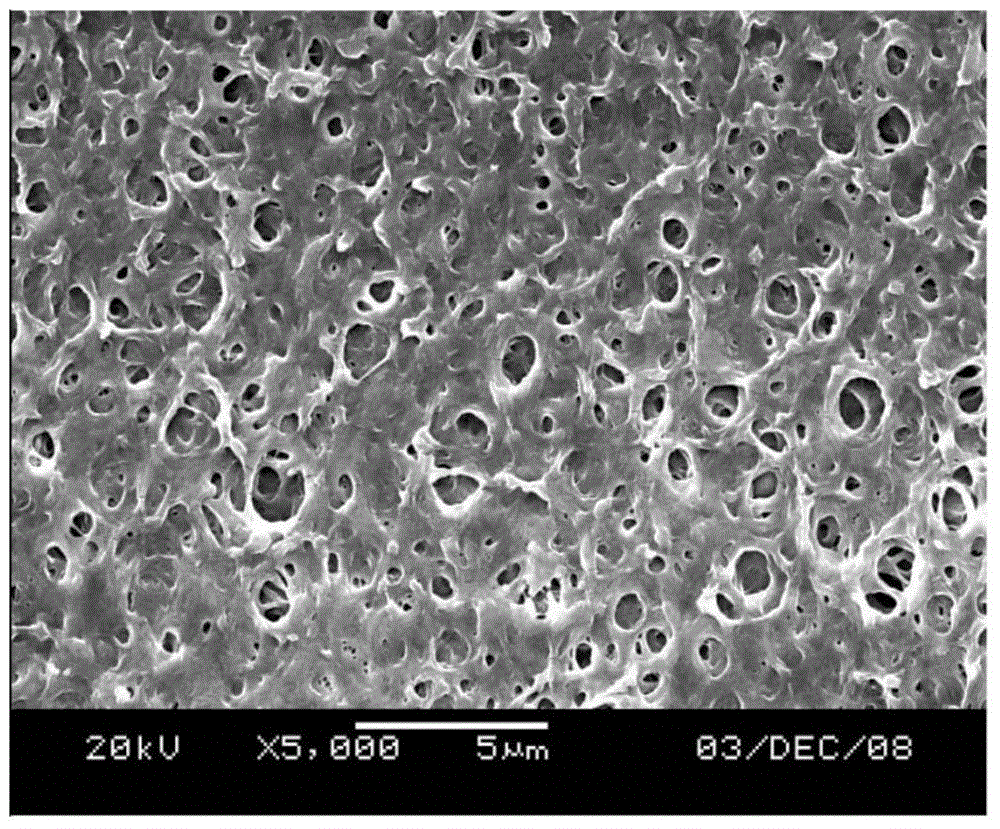

[0045] Get polyethylene microporous membrane as base material, its thickness is 9 μm, 0.3g thickening agent sodium carboxymethyl cellulose (molecular weight is about 6.0×10 4 ) was dispersed in 105 g of deionized water and stirred at a controlled speed of 1500 r / min, and stirred for 0.5 h. Then 75g of alumina (particle size D50 is 200nm) and 25g of polyvinylidene fluoride-hexafluoropropylene (molecular weight is 200,000, average particle size is 10 μm) are added step by step into the solution and stirred at high speed, the control speed is 2500r / min, Stir for 2h. Then add 10 g of the binder polyacrylate emulsion into the suspension, control the stirring speed to 2500 r / min, and stir for 1 hour to obtain the slurry. The slurry is evenly coated on one side of the substrate, and the wet film thickness on one side is controlled to be 10-20 μm. Then place the wet coating at 38~50℃ to blow dry, control the air volume to 30m 3 / h, and the drying time was controlled for 5-10 minute...

specific Embodiment 2

[0046] Get polyethylene microporous membrane as base material, its thickness is 9 μm, 0.3g thickening agent sodium carboxymethyl cellulose (molecular weight is about 6.0×10 4 ) was dispersed in 105 g of deionized water and stirred at a controlled speed of 1500 r / min, and stirred for 0.5 h. Then 70g of alumina (particle size D50 is 800nm) and 30g of polyvinylidene fluoride-hexafluoropropylene (molecular weight is 2 million, average particle size is 8 μ m) are added to the solution step by step and stirred at high speed, the control speed is 2500r / min, Stir for 2h. Then add 10 g of the binder polyacrylate emulsion into the suspension, control the stirring speed to 2500 r / min, and stir for 1 h. That is, the slurry is obtained. The slurry is evenly coated on one side of the substrate, and the wet film thickness on one side is controlled to be 10-20 μm. Then place the wet coating at 38~50℃ to blow dry, control the air volume to 30m 3 / h, and the drying time was controlled for 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com