Preparation of graphene-slag-based conducting functional composite material and application of graphene-slag-based conducting functional composite material in sewage treatment

A functional composite material, graphene technology, applied in the field of preparation of graphene-slag-based conductive functional composite materials, can solve problems such as the preparation method of graphene-slag-based conductive functional composite materials has not been found

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Accurately take by weighing 1500g of the granulated blast furnace slag powder raw material, take this as the measurement basis (100%), adopt the external mixing method, the graphene dosage is 0.01% of the granulated blast furnace slag powder weight, and the dosage of solid sodium hydroxide is granulated The mass ratio of water to granulated blast furnace slag powder is 0.28. Pour the granulated blast furnace slag powder and graphene into a double-rotation and double-speed slurry mixer, and stir evenly; dissolve solid sodium hydroxide in water to prepare an aqueous sodium hydroxide solution. Add the sodium hydroxide aqueous solution to the uniformly stirred material, and form a uniformly mixed slurry after chemical reaction under high-speed stirring;

[0062] Put the slurry into a triple mold of 40mm×40mm×160mm, and vibrate it on the mortar vibrating table; put the formed test block into the standard curing box for 1 day and then remove the mold. After curing for 2 days...

Embodiment 2

[0064] All operation steps are identical with embodiment 1, just change the quality of graphene into 0.02% of granulated blast furnace slag powder quality, obtain graphene-slag-based conductive function composite material test block mark as: GE / GBFS2), detect test block 3d compressive and flexural strength, the strength data are shown in Table 2.

Embodiment 3

[0066] Under the premise of not adding graphene, all operation steps are the same as embodiment 1, obtain the graphene-slag-based conductive functional composite material test block (marked as: GBFS), detect the compressive and flexural strength of test block 3d, its strength The data are shown in Table 2.

[0067] Table 2: Compressive and flexural strength of test block 3d

[0068]

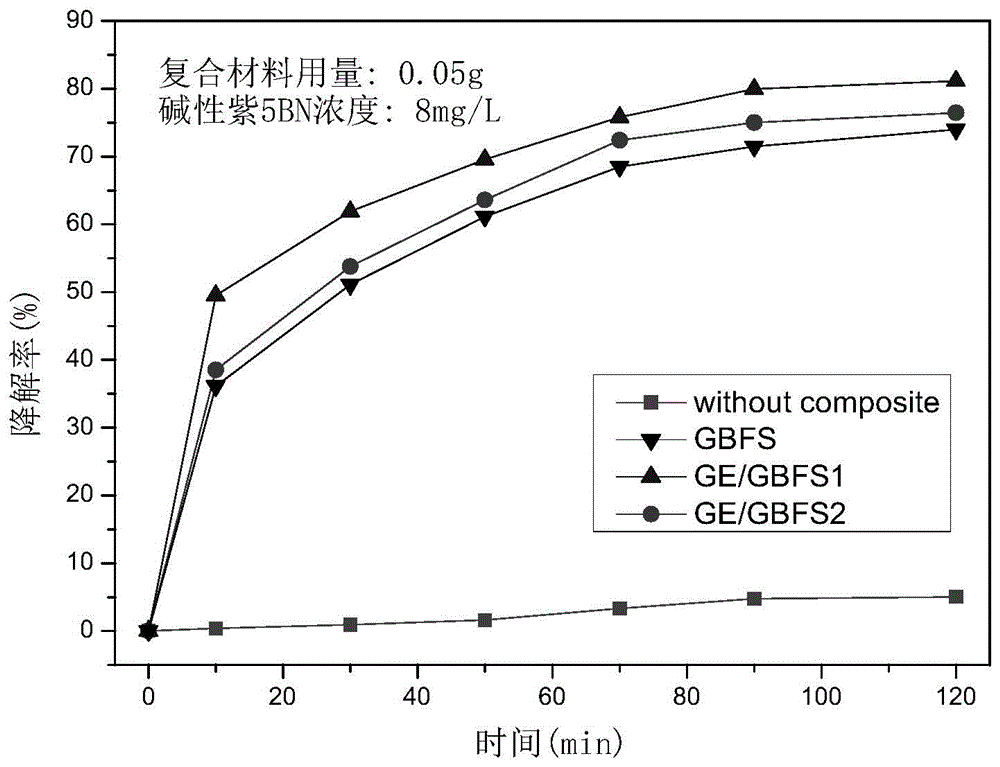

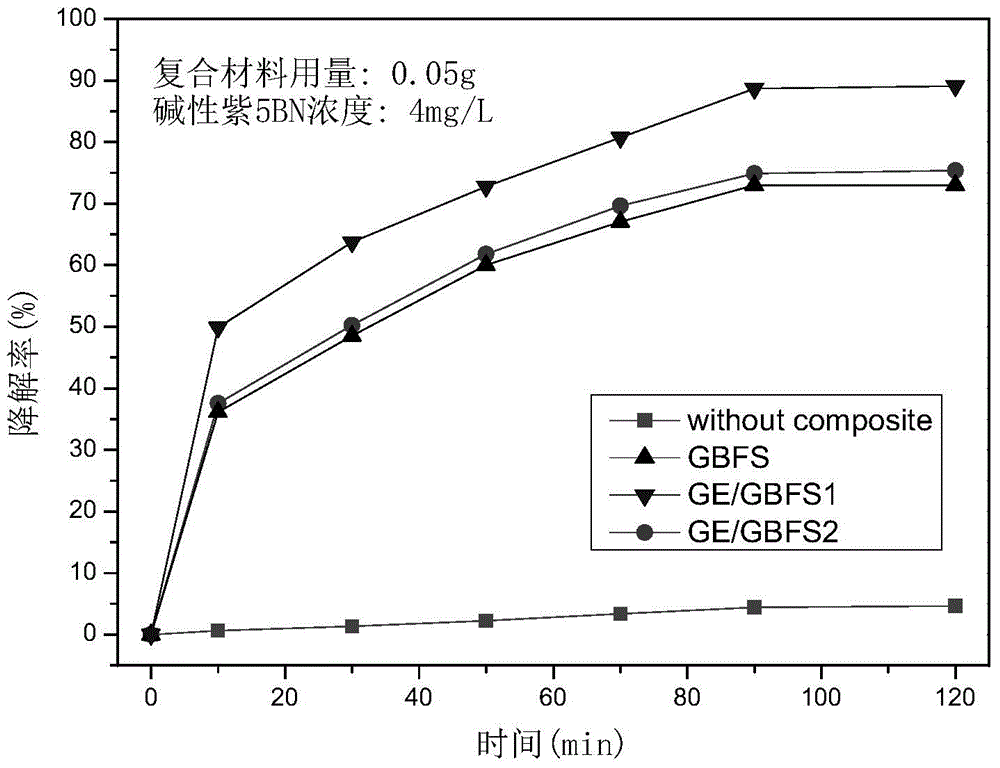

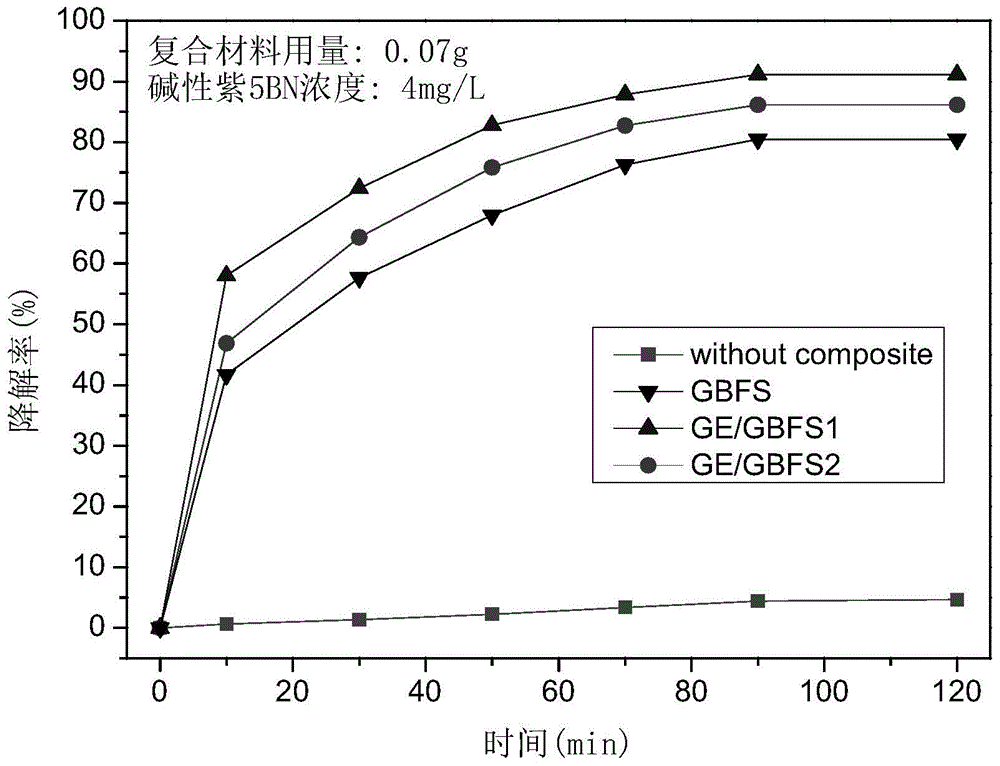

[0069] Proved by the applicant's experiments, the graphene-slag-based conductive functional composite material prepared by the present invention can be applied to the sewage treatment of organic dyes, specifically according to the following steps:

[0070] (1) Prepare a certain volume of basic violet 5BN simulated industrial wastewater with a volumetric flask; measure its initial absorbance A with an ultraviolet-visible light spectrophotometer o ;

[0071] (2) Put a certain amount of graphene-slag-based conductive functional composite material into a beaker of basic violet 5BN simulating ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com