Graphene modified polyvinylidene fluoride hollow fiber ultrafiltration membrane and preparation method thereof

A polyvinylidene fluoride, graphene modification technology, applied in ultrafiltration, separation methods, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A preparation method of a graphene-modified polyvinylidene fluoride hollow fiber ultrafiltration membrane, the specific steps are:

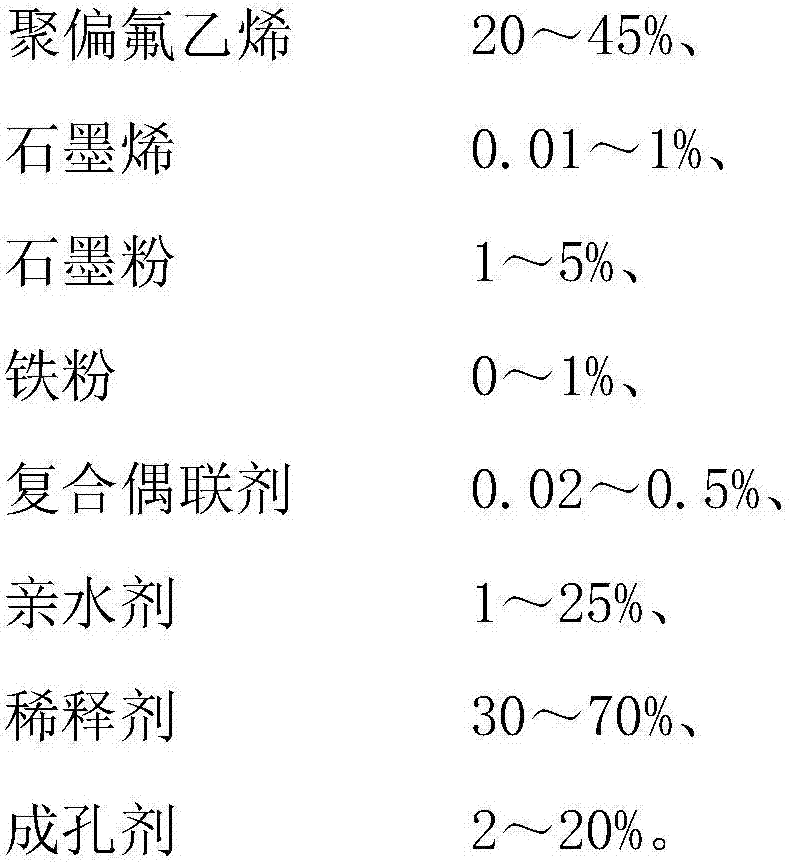

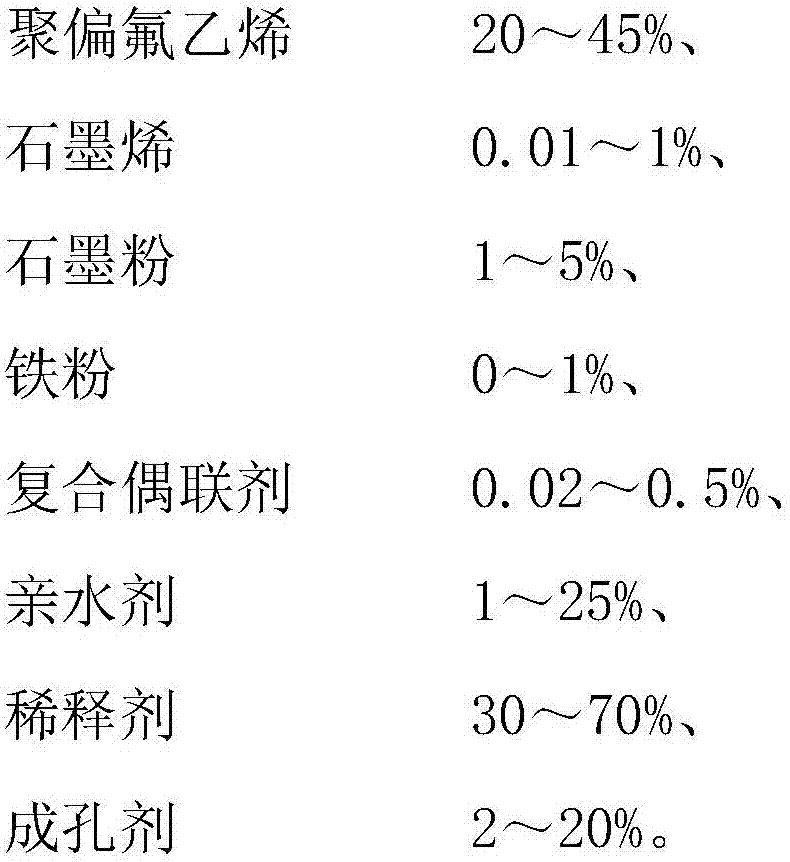

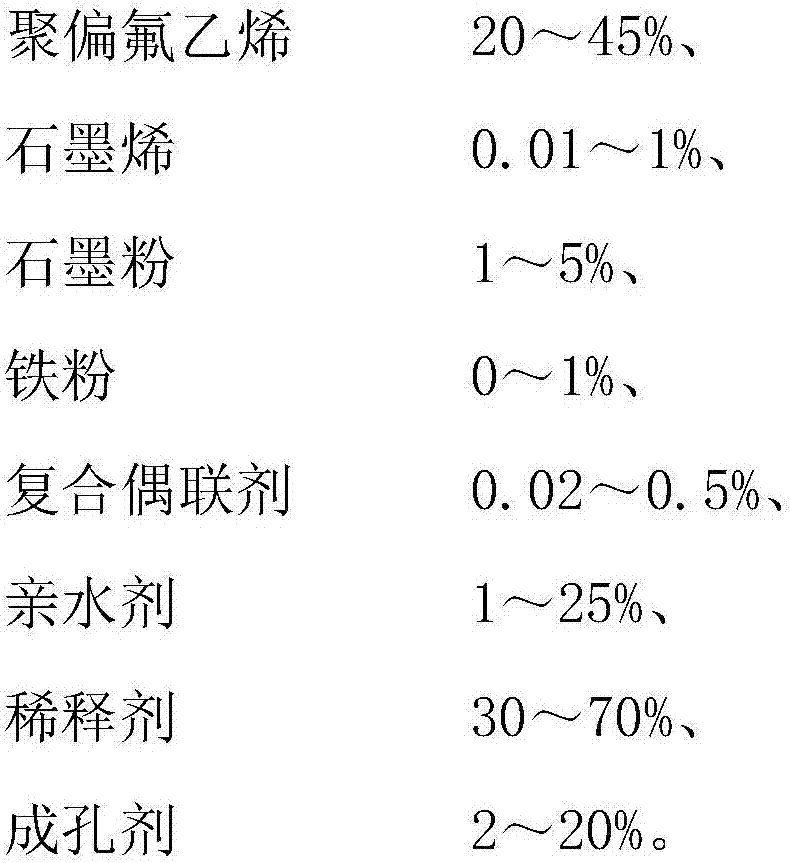

[0026] In order to effectively disperse graphene in polyvinylidene fluoride and to reduce costs, firstly, 0.01-1% graphene and 1-5% graphite powder are pre-mixed and microwave-dried, and then 0.02-0.5 % composite coupling agent, 0-1% iron powder, 20-45% polyvinylidene fluoride, mixed at high speed;

[0027] Add 1-25% of hydrophilic agent, 2-20% of pore-forming agent, and 30-70% of diluent in sequence to the above-mentioned high-speed mixed ingredients, and mix evenly to make a film-making material;

[0028] The hollow fiber ultrafiltration membrane is prepared by the thermal phase method, and the membrane material is poured into a twin-screw extruder at 200-400 ° C to heat it to a molten state; the melted membrane material passes through the hollow fiber membrane die After extrusion, it is cooled into a hollow fiber tube;

[0029] Pass c...

Embodiment 1

[0039] Pre-mix 0.2% graphene and 5% graphite powder and microwave dry, then add 0.5% composite coupling agent, 0% iron powder, 20% polyvinylidene fluoride, and mix at high speed;

[0040] Add 10% hydrophilic agent, 2% pore forming agent, and 30-62.3% diluent in sequence to the above-mentioned high-speed mixed ingredients, and mix evenly to make a film-making material;

[0041] Pour the film-making material into a twin-screw extruder at 200°C and heat it to a molten state; the melted film-making material is extruded through the hollow fiber membrane die and cooled to form a hollow fiber tube;

[0042] Pass compressed air or high-boiling-point non-solvent into the hollow fiber tube as the core liquid, and then send the hollow fiber tube into a gas-phase or liquid-phase separation tank to separate the diluent and pore-forming agent in the film-making material to obtain graphene Modified polyvinylidene fluoride hollow fiber ultrafiltration membrane.

[0043] The outer diameter of...

Embodiment 2

[0045] Pre-mix 1% graphene and 2% graphite powder and microwave dry, then add 0.15% composite coupling agent, 0.5% iron powder, 45% polyvinylidene fluoride, and mix at high speed;

[0046] Add 5% of hydrophilic agent, 16.35% of pore forming agent, and 30% of diluent in sequence to the above-mentioned high-speed mixed ingredients, and mix evenly to make a film-making material;

[0047] Pour the film-making material into a twin-screw extruder at 400°C and heat it to a molten state; the melted film-making material is extruded through the hollow fiber membrane die and cooled to form a hollow fiber tube;

[0048] Pass compressed air or high-boiling-point non-solvent into the hollow fiber tube as the core liquid, and then send the hollow fiber tube into a gas-phase or liquid-phase separation tank to separate the diluent and pore-forming agent in the film-making material to obtain graphene Modified polyvinylidene fluoride hollow fiber ultrafiltration membrane.

[0049] The outer dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Separation aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com