Artificial human skeleton manufacturing method based on radiation detection

A technology of simulating human body and radiation detection, which is applied in the interdisciplinary field of science, engineering and medicine, can solve the problems of boneless morphology inspection, mass density inspection, standardization, serialization and commercial production, and the inability to solve the interconnection of bone tissues and brackets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, and the raw material described in the embodiment is common commercially available product unless otherwise specified.

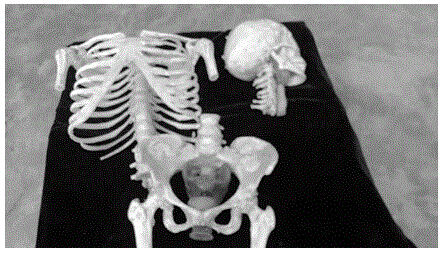

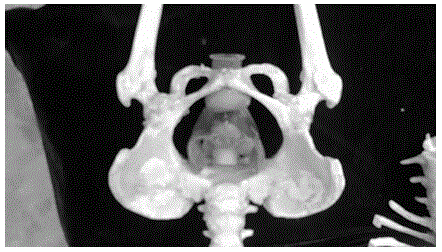

[0022] figure 1 It is a schematic diagram of the simulated human skeleton of the present invention; figure 2 It is a schematic diagram of the movable connection parts of the simulated human skeleton in the present invention, which uses artificial bionic joints, spherical joints or hinge joints to realize the movable connection, or uses stoppers, friction plates or locking plastic screws for fixed connection; image 3 It is a non-uniform mosaic structure diagram of the simulated human skeleton hip in the present invention.

[0023] One, basic principle of the present invention:

[0024] 1. The method of obtaining the shape and size of the human skeleton:

[0025] Obtain the bone tissue, skeleton and external overall sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com