Nanometer iron-manganese composite oxide loaded gas diffusion electrode and preparation and application thereof

A technology of gas diffusion electrodes and composite oxides, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of reducing the catalytic efficiency of catalysts, and achieve the effect of broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

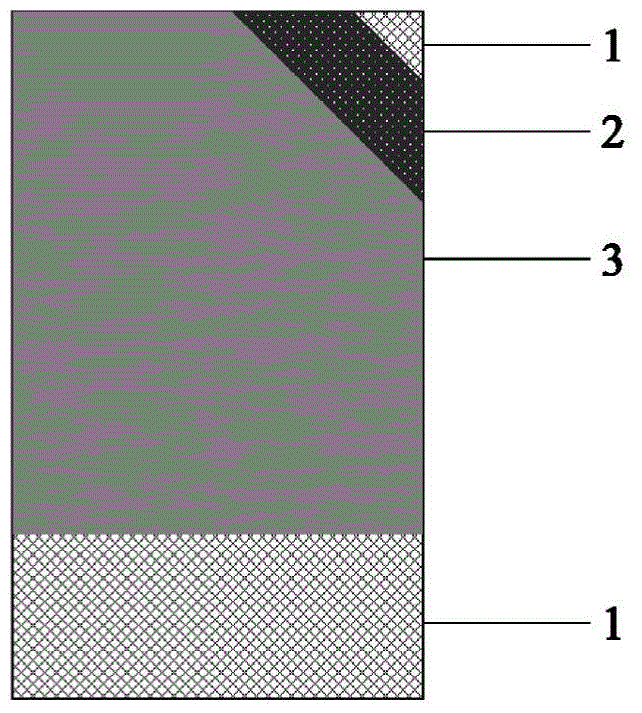

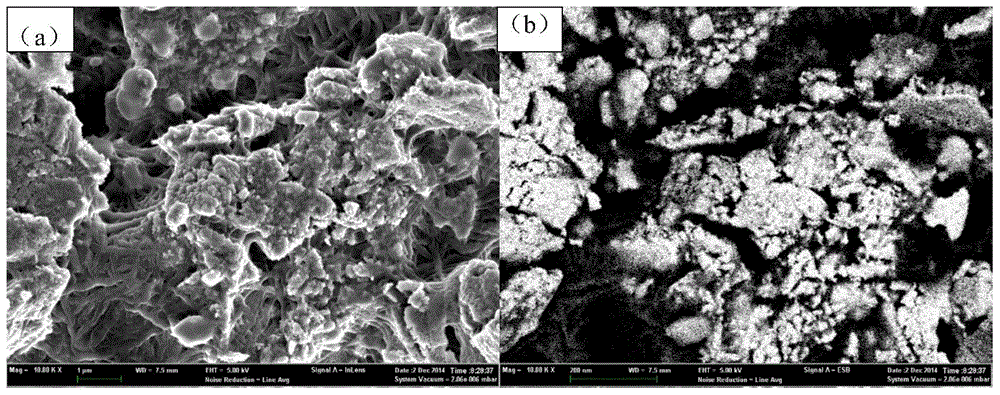

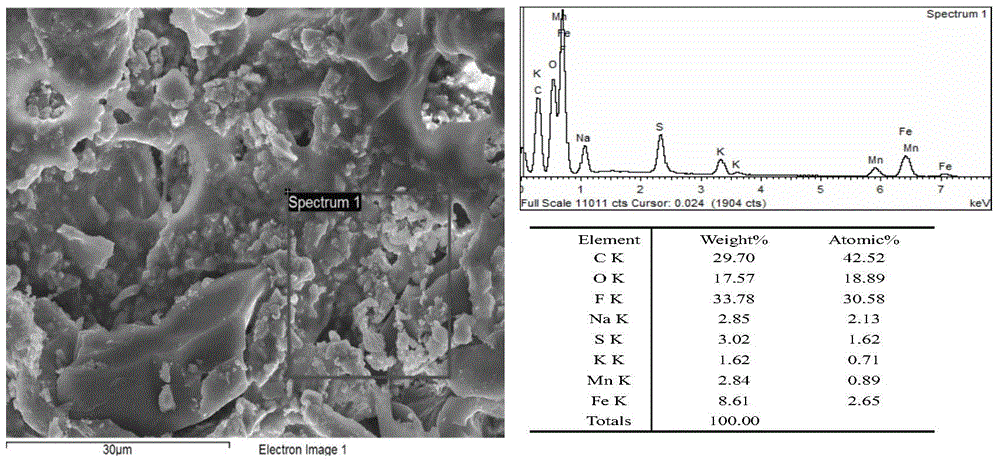

Image

Examples

Embodiment 1

[0058] The gas diffusion electrode supported by nano-iron-manganese composite oxide is used as the cathode, and the graphite rod is used as the anode to construct an electro-Fenton system to treat nitrobenzene wastewater. The specific steps of the test are as follows:

[0059] 1. Prepare nitrobenzene stock solution (100ppm), stir overnight;

[0060] 2. Add 0.05M sodium sulfate electrolyte and stir until dissolved;

[0061] 3. Adjust the pH to 7.0;

[0062] 4. Adjust the aeration flow rate to 200ml / min, and the current density to 30mA / cm 2 , the timing starts to react;

[0063] 5. Sampling 5 mL at 0, 5, 10, 15, 20, 30, 60, 90, and 120 min respectively; after sampling, add 2 drops of 2M NaOH to terminate the reaction (adjust the pH to 10);

[0064] 6. Filter 2mL water sample, analyze the sample nitrobenzene concentration by GC-MS; filter 2.5mL water sample, dilute to 25mL, measure the sample TOC concentration;

[0065] Test conditions: 400mL reaction solution; 0.05MNa 2 SO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com