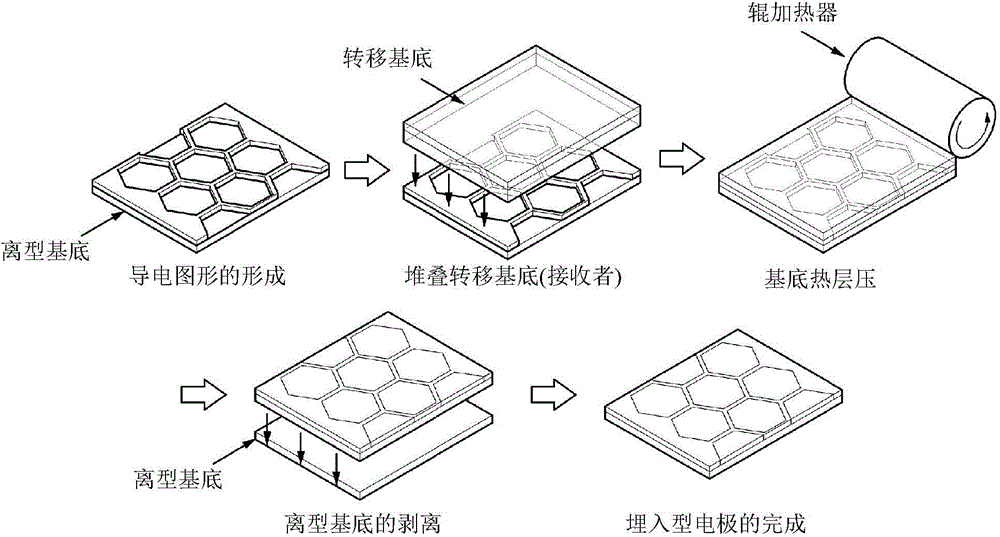

Manufacturing method of flexible buried electrode film using thermal lamination transfer

A flexible electrode and thin film technology, which is applied in the direction of thermoplastic polymer dielectric, printed circuit manufacturing, cable/conductor manufacturing, etc., can solve the problems of conductive thin film, wet dissolution speed reduction, etc., to prevent pattern damage or short circuit, excellent resistance value , Eliminate the effect of plane difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0102] A PET substrate with a thickness of 180 μm was coated with a 5 mm thick polydimethylsiloxane (PDMS) (SYLGARD 184, purchased from Dow Corning Corp.) solution (mixing ratio 1:9), and then cured at 70 °C for 6 hours to prepare a release substrate. Using e-electron beam deposition machine (base pressure: 8×10 -7 Torr, working pressure: 5×10 -5 trust, ) A 150 nm thick Al foil was deposited on the release surface of the release substrate.

[0103] Using AZ1518 photoresist, coating, drying, mask exposure and development were performed to form a pattern on the Al deposition film.

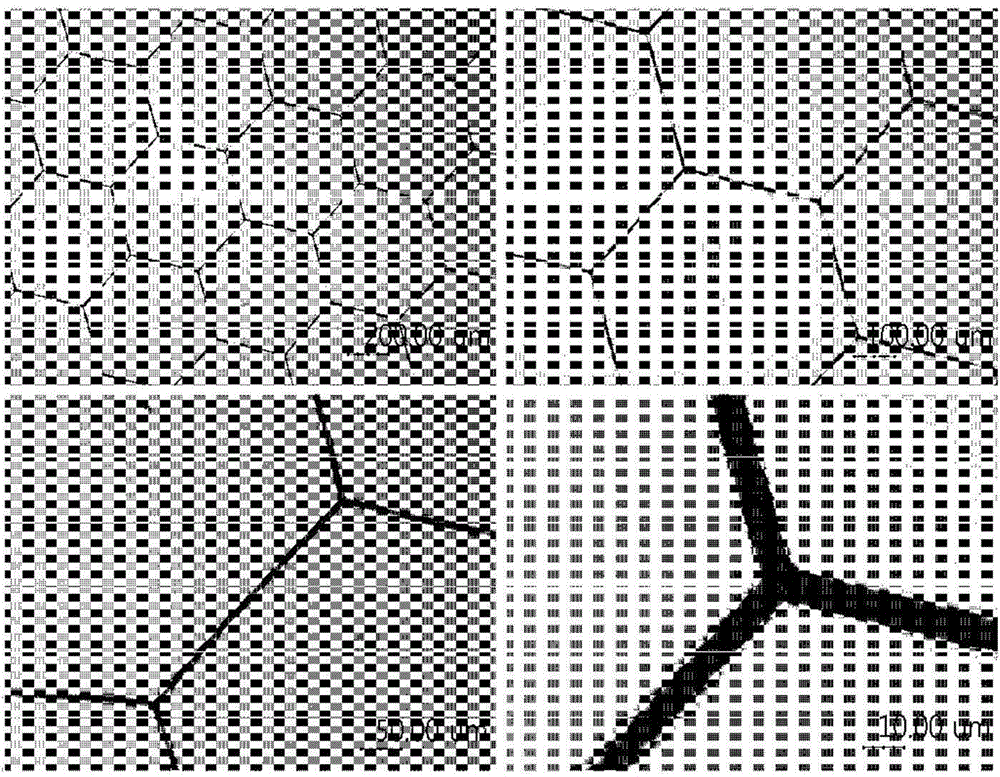

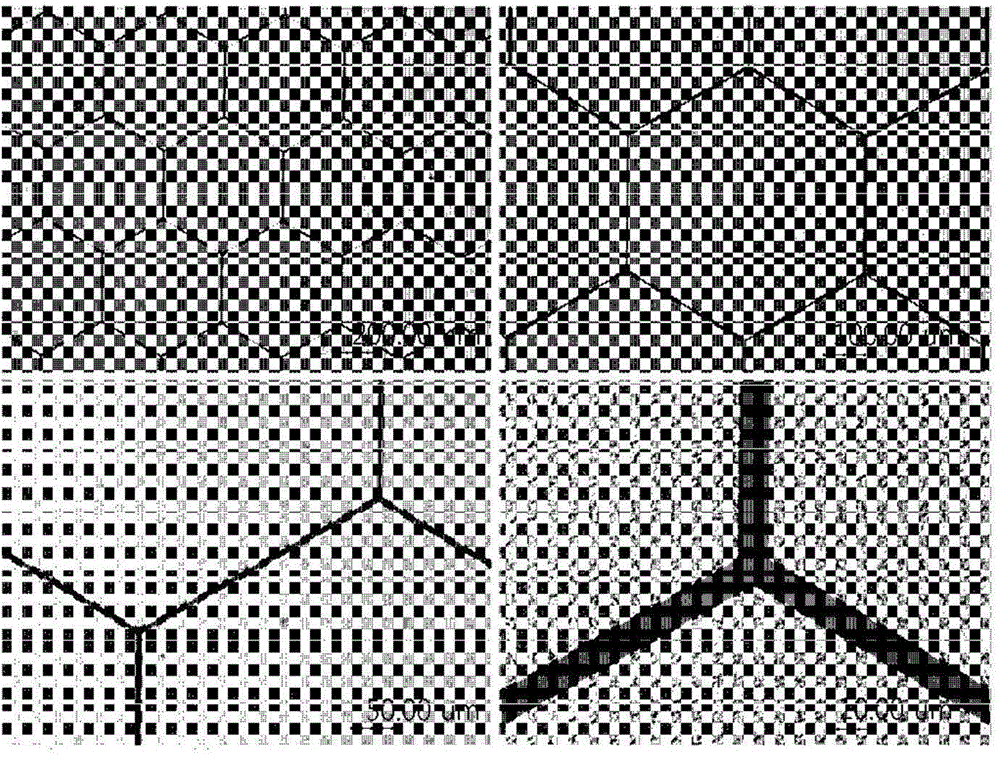

[0104] The formed photoresist pattern is subjected to wet etching (phosphoric acid-based Al etching solution) or dry etching (ICP-RIE) to form an Al electrode pattern. Based on observations through an optical microscope, such as figure 2 Al electrode patterns are formed as shown.

[0105] On the Al electrode pattern, place a 250 μm EVA (ethylene vinyl acetate) film (pouch laminating film, pur...

example 2

[0108] Fabricate the flexible conductive embedded electrode film in the same manner as in Example 1, the difference is that, with 1~5wt% dilute fluorinated silane (OPTOOL TM , purchased from Daikin Industries, LTD.) solution was spin-coated on a PET substrate with a thickness of 180 μm, and then dried at 120° C. for 30 minutes to prepare a release substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com