High voltage gradient zinc oxide based varistor material and preparation method thereof

A zinc oxide-based, varistor technology, applied in the field of varistor material manufacturing, can solve problems such as lowering the sintering temperature of zinc oxide varistors, improve potential gradient and large current flow capacity, reduce weight, and increase particle size The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

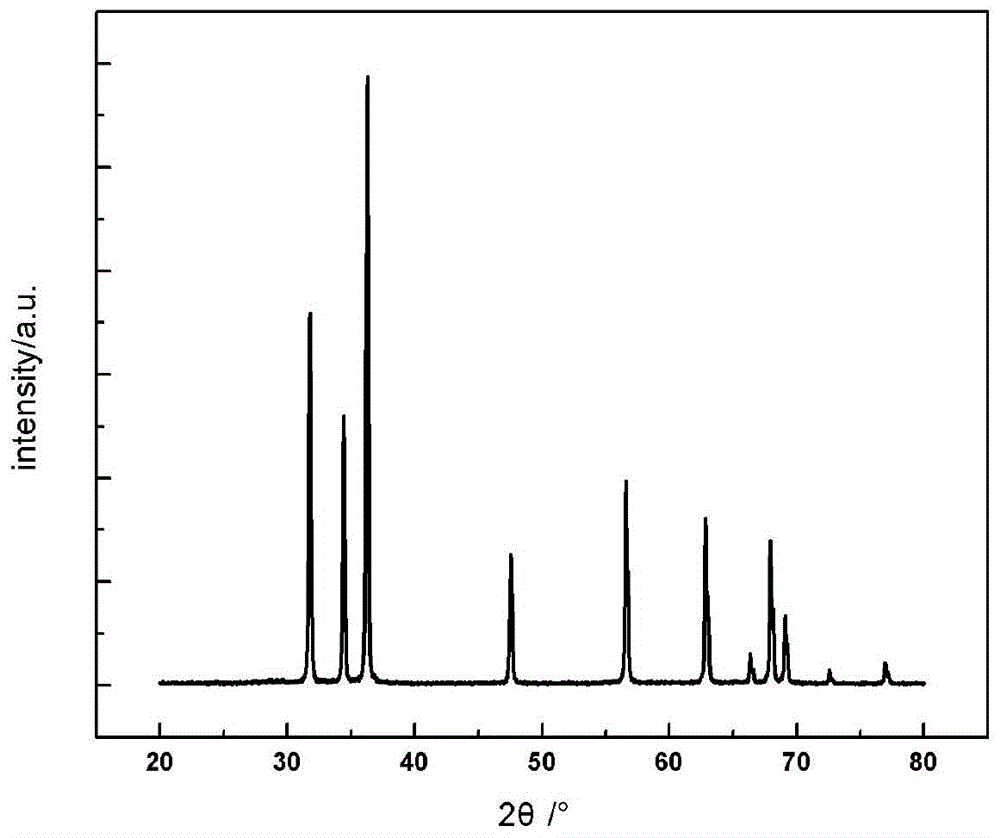

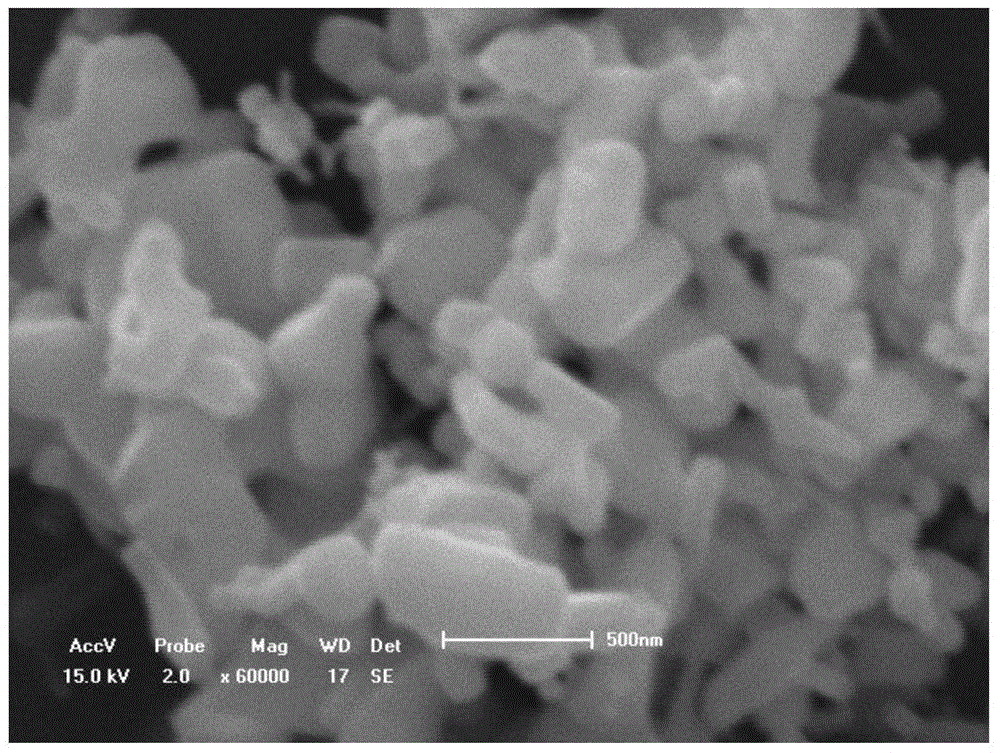

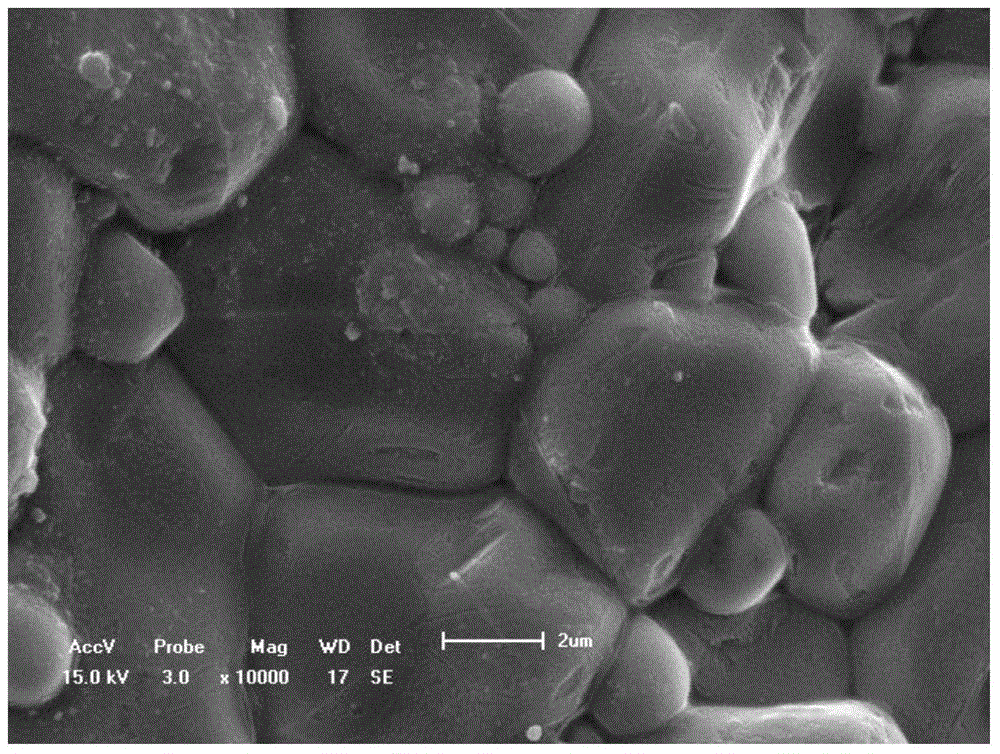

Image

Examples

Embodiment 1

[0020] A high-voltage gradient zinc oxide-based varistor material, calculated by molar ratio, consists of the following components: ZnO90%; Bi 2 o 3 2.4%; Pr 2 o 3 / La 2 o 3 0.5%; Sb 2 o 3 3.0%;Co 2 o 3 1.5%; 2 o 3 0.5%; MnCO 3 / MnO 2 0.4%;Cr 2 o 3 0.5%;Al 2 o 3 0.03%; Y 2 o 3 0.5%; B 2 o 30.6%; MgO0.07%. Bi in the above formula 2 o 3 、Pr 2 o 3 / La 2 o 3 , Sb 2 o 3 、Co 2 o 3 、Ni 2 o 3 , MnO 2 、Cr 2 o 3 、Al 2 o 3 , Y 2 o 3 , B 2 o 3 Both MgO and MgO were introduced in the form of metal salt solution.

[0021] The preparation method adopts the chemical co-precipitation method to prepare the composite dopant. The precipitating agent is ethanolamine, and the pH value of the solution is controlled between 6-8. After a certain period of reaction, the precipitate is washed three times with deionized water, and then washed with ethanol. After the agent is ground, it is ready for use. The specific steps are:

[0022] a. ZnO90% and the composi...

Embodiment 2

[0030] A high-voltage gradient zinc oxide-based varistor material, calculated by molar ratio, consists of the following components: ZnO86%; Bi 2 o 3 4.0%; Pr 2 o 3 / La 2 o 3 0.5%; Sb 2 O 3 2% ; 2 o 3 ~1.8%; Ni 2 o 3 1.0%; MnCO 3 / MnO 2 0.9%;Cr 2 o 3 0.8%;Al 2 o 3 0.02% ;Y 2 o 3 0.5%; B 2 o 3 0.05% and MgO0.05%, also contains the following molar ratio of SiO 2 1%; 2 o 3 1%; 2 o 3 0.38%.

[0031] The preparation method is the same as in Example 1.

[0032] The performance test of the zinc oxide-based varistor composite powder prepared in this example shows that the potential gradient is as high as 1520 V / mm, the leakage current is 3.1 μA, and the nonlinear coefficient is 62.

Embodiment 3

[0034] A high-voltage gradient zinc oxide-based varistor material, calculated by molar ratio, consists of the following active ingredients: ZnO96%; Bi 2 o 3 1%; 2 o 3 / La 2 o 3 0.16%; Sb 2 O 3 0.5% ; 2 o 3 0.5%;Ni 2 o 3 0.05%; MnCO 3 / MnO 2 0.5%;Cr 2 o 3 0.5%;Al 2 o 3 0.02% ;Y 2 o 3 0.5%; B 2 o 3 0.05% and MgO0.03%, also contains Ga 2 o 3 0.19%.

[0035] The preparation method is the same as in Example 1.

[0036] The performance test of the zinc oxide-based varistor composite powder prepared in this example shows that the potential gradient is as high as 1720 V / mm, the leakage current is 2.9 μA, and the nonlinear coefficient is 59.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Potential gradient | aaaaa | aaaaa |

| Leakage current | aaaaa | aaaaa |

| Potential gradient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com