Multifunctional anionic polymer composite additive and preparation technology thereof

A composite additive and negative ion technology, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of no polymer chain and not very considerable physical modification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A kind of preparation method of multifunctional negative ion macromolecule compound additive is characterized in that comprising following processing step:

[0039] a) Add the initiator and polar solvent in the above parts by weight to the organic solution of 1,3-butadiene under the condition of nitrogen flow, and react at a temperature of 20-70° C. for 60-300 minutes;

[0040] B) adding the nano-anion additive of above-mentioned parts by weight and stirring;

[0041] c) heating up to 50-100°C, adding the above-mentioned parts by weight of styrene and divinylbenzene, and reacting for 100-300 minutes;

[0042] D) adding the chain terminator reaction of above-mentioned parts by weight;

[0043] e) cooling to normal temperature, and pumping to constant weight in a vacuum oven;

[0044] F) adding the nano-anion additive and ethylene dichloride of the above-mentioned parts by weight to the product and stirring;

[0045] g) adding carbon tetrachloride and anhydrous aluminu...

Embodiment 1

[0057] The following experiments were all carried out under the condition of nitrogen protection. A certain mass of polar solvent and n-butyllithium were added to 200ml of cyclohexane solvent and stirred evenly. The temperature was raised to 50°C, and 60.021g of 1,3- Butadiene, reacted for 180 minutes, added 50.276g of nano-anion additives with a particle size of 5nm-100nm, stirred evenly, raised the temperature to 70°C, added 10.191g of styrene and 15.121g of divinylbenzene, reacted for 180 minutes, added 1.095 g of ethanol, reacted for 60 minutes, cooled to normal temperature, put the product in a vacuum oven, baked at 90°C for 12 hours to constant weight to obtain 131.731 g of product, dissolved the product in a certain quality of dichloroethane, and added 60.984 Add a certain amount of carbon tetrachloride and anhydrous aluminum trichloride, and react at 30°C for 13 hours, then use acetone, dilute hydrochloric acid and water to dissolve It is washed, the product is put in ...

Embodiment 2

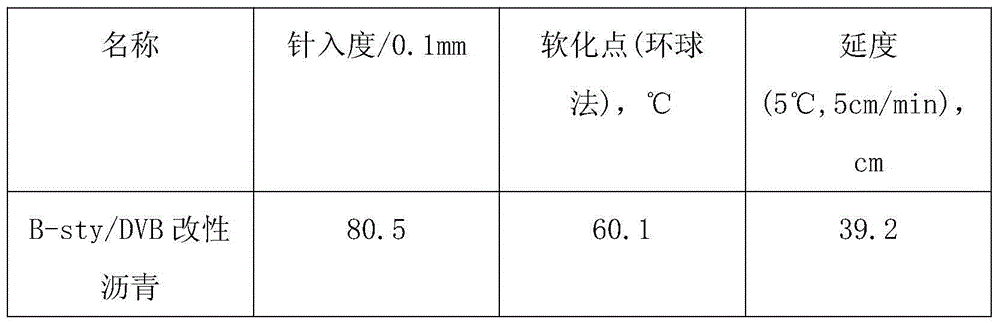

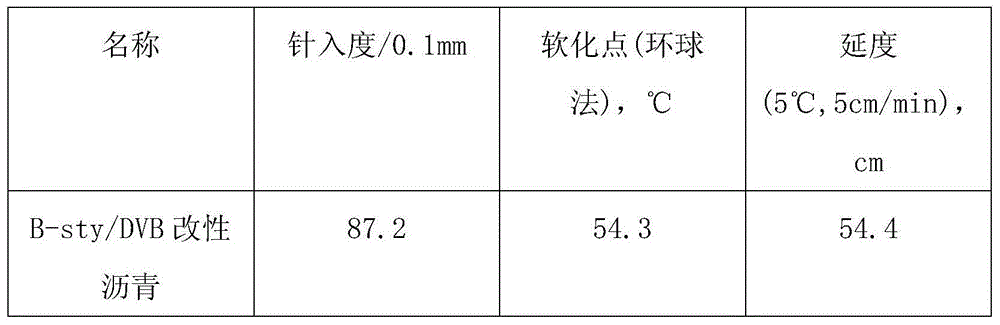

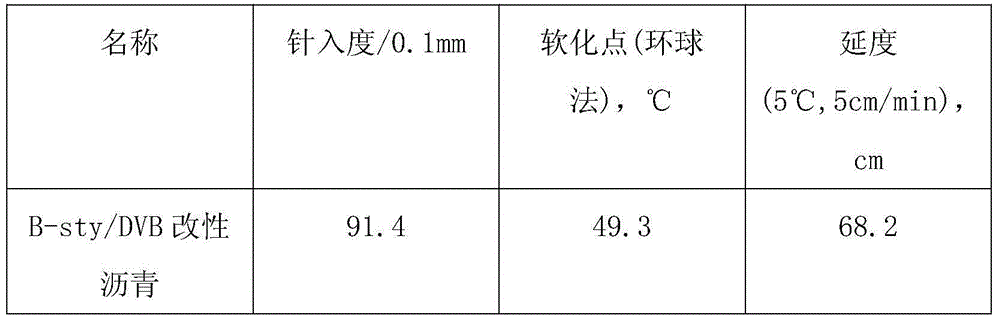

[0064] Use a grinder to grind the additive into 350-500 mesh particles, 500 grams of No. 90 bitumen from Sinopec as the base bitumen, add 12.5 grams of petroleum fractions with an aromatic content of 90.27% into the base bitumen, and stir at 160 degrees Celsius For 30 minutes, heat the base asphalt to 190 degrees Celsius, add 30 grams of additive particles, and shear at a high speed of 4500 rpm for 25 minutes by a high-speed shearer, then add 4.5 grams of sulfur powder, and then shear at a speed of 4500 rpm for 30 minutes , to obtain the final modified asphalt.

[0065] Use the national standard GB / T 4509-2010 method to test its penetration, use the national standard GB / T 4508-2010 method to test its ductility, use the national standard GB / T 4507-1999 method to test its softening point (ring and ball method), the test results are as follows :

[0066]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com