Alloy material with high strength as well as ductility and semi-solid state sintering preparation method and application of alloy material

一种半固态烧结、韧合金的技术,应用在合金材料制备领域,能够解决难以保证第二相分布均匀、冷却速率受限、合金润湿性差等问题,达到良好推广应用前景、广泛通用性和实用性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

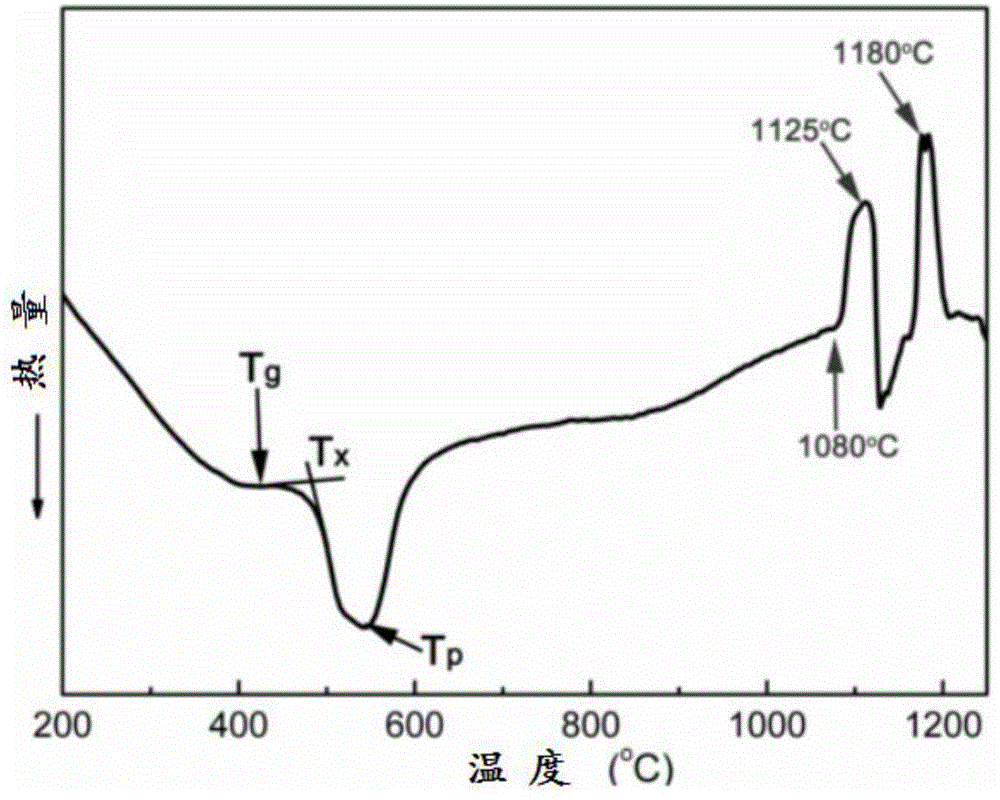

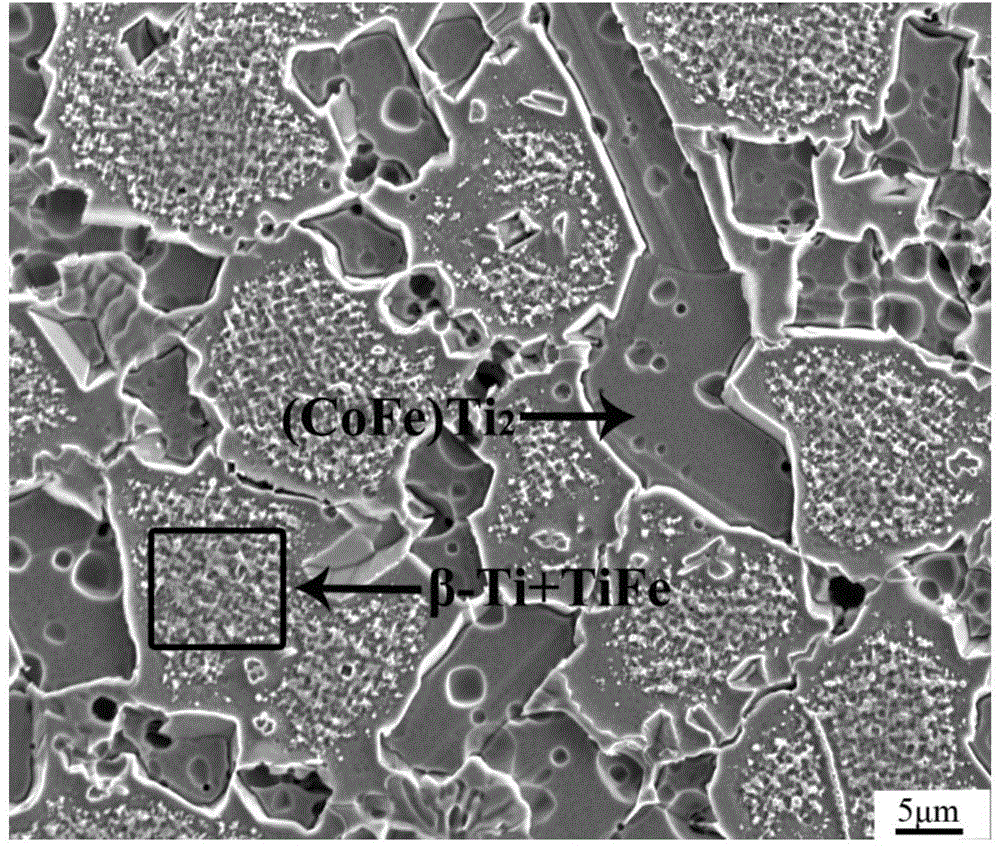

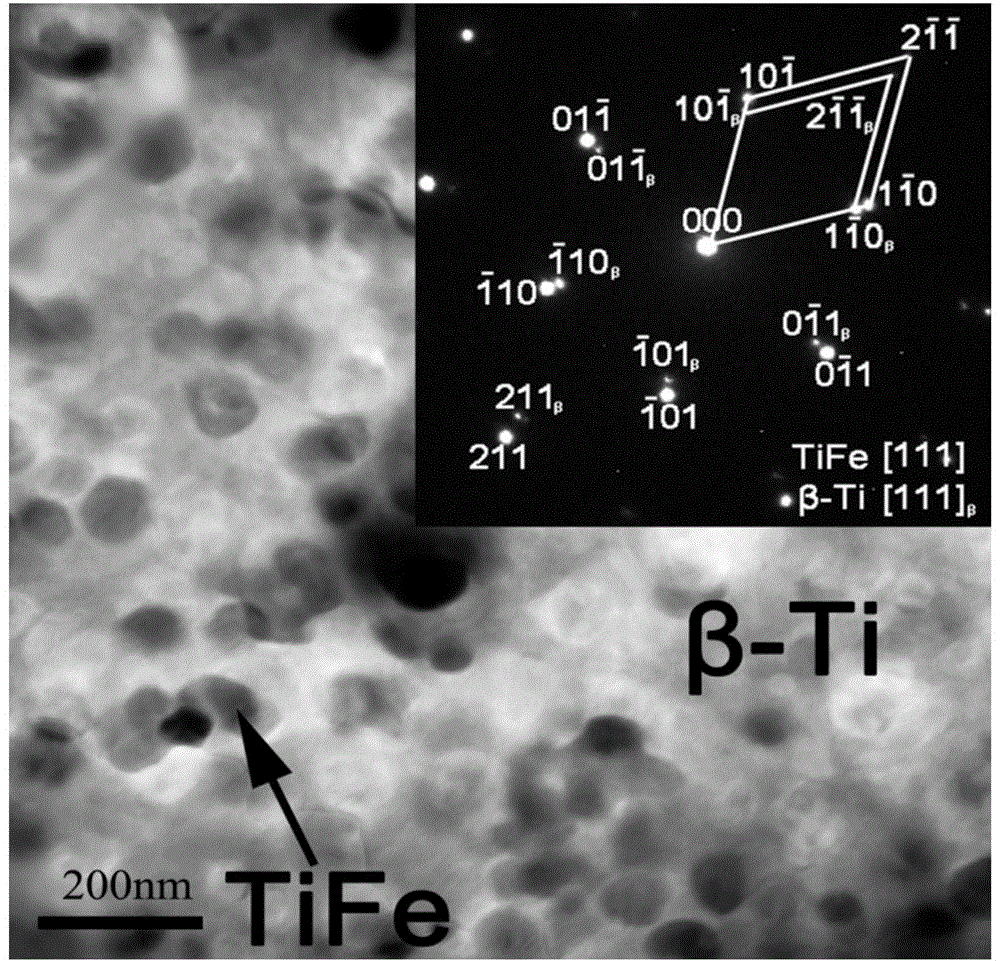

[0044] Example 1: Preparation of a high-strength and toughness dual-scale structure titanium alloy

[0045] Semi-solid sintering preparation method, the specific steps are as follows:

[0046] Step 1: Mix the powder

[0047] Pick Ti 62 Nb 12.2 Fe 13.6 Co 13.6 Al 5.8 Alloy system, according to the mass ratio of the selected alloy system, the powder is batched. In this example, the elemental powder prepared by the atomization method with a particle size of 7.5 μm is selected, but the powder raw material of the present invention is not limited to this, and the elemental powder can also be an electrolysis method, etc. The particle size of the powder prepared by other methods is not specifically limited, and it can be a fine powder or a relatively coarse powder. Mix the above elemental powders uniformly in a mixer. In this example, a Ti-based alloy system is preferred, but the alloy system selected in the present invention is not limited to this, and can also be selected fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com