Pressure sucking-based cell/particle sorting system and method

A sorting system, cell technology, applied in the field of biotechnology and instrument science, can solve problems such as restriction and disturbance of fluid flow pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Raman activated single cell sorting based on pressure sucking

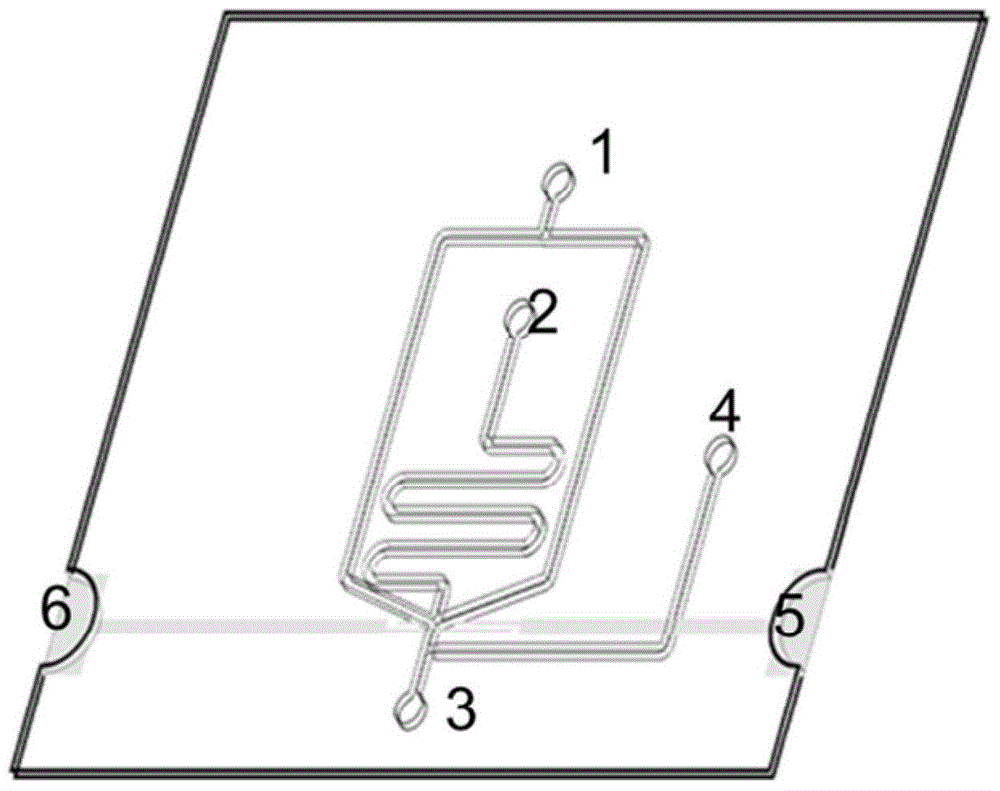

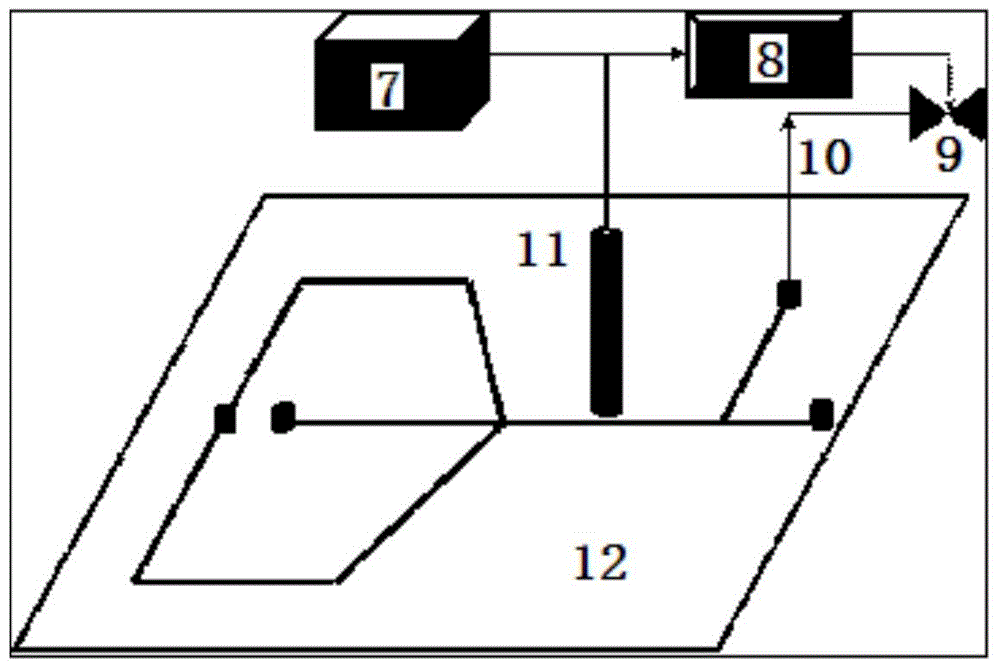

[0033] Such as figure 1 , 2 As shown, the quartz microfluidic chip constructed in this example is used for single-cell sorting based on pressure-sucking Raman activation in the flow state. The chip structure is shown in figure 1 , including 1. Precision micropump or static pressure driven entrainment buffer inlet; 2. Precision micropump or static pressure driven cell suspension inlet; 3. Waste liquid outlet; 4. Sorted cell / particle outlet for The liquid conduit 10 is connected with the solenoid valve 9; 5, 6, the electrode pair are connected with the output of the high-frequency AC signal generator. The chip is composed of upper and lower quartz substrates. The cover sheet includes a microchannel network of 20-150 microns wide and 10-50 microns deep by wet etching. The micro-electrode structure on the lower quartz substrate is obtained by photolithography and electrode etching solution. etched...

Embodiment 2

[0034] Example 2: Fluorescence cell sorting based on pressure suction

[0035] The microfluidic chip constructed in this example is used for fluorescent cell sorting based on pressure suction in a flowing state. Outlet 4 is the same as the pressure deflection control port. The microfluidic chip 12 is composed of upper and lower substrates, the upper substrate includes a microchannel network with a width of 20-150 microns and a depth of 10-50 microns, and the lower layer is a cover sheet. The upper and lower substrates are cleaned, aligned precisely under a microscope, and then bonded. The outlet and inlet of the chip are connected to the outside world through fixed interfaces and microtubules to realize the introduction and separation of cells / particles. The microfluidic chip 12 and related methods described in this example realize the sorting of single cells based on pressure sucking Raman activation in a flow state. Cells (expressed with fluorescent protein) are diluted t...

Embodiment 3

[0036] Example 3: Sorting of microdroplets based on pressure suction

[0037]The microfluidic chip 12 and method constructed in this example are used for sorting fluorescent micro-droplets based on pressure sucking in a flowing state. The chip structure includes: 1. Oil phase inlet (entrainment buffer inlet); 2. Droplet inlet (cell suspension inlet); 3. Waste liquid outlet; 4. Sorting droplet outlet (sorting cell / particle outlet), the droplet collection port is the same as the pressure deflection control port. The chip is composed of upper and lower substrates, the upper substrate includes a microchannel network with a width of 20-150 microns and a depth of 10-50 microns, and the lower layer is a cover sheet. The upper and lower substrates are cleaned, aligned precisely under a microscope, and then bonded. The outlet and inlet of the chip are connected to the outside world through fixed interfaces and microtubules to realize the introduction and separation of cells / particles....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com