Manufacturing method of MEMS chip insensitive to packaging stress and MEMS chip

A technology of packaging stress and manufacturing method, which is applied in the field of MEMS chips, can solve the problems that the contact area affects the ability of MEMS devices to resist mechanical impact, the soft glue cannot withstand too high temperature, and the MEMS devices cannot work, etc., so as to simplify the wafer processing process , Reduce material cost, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, and the protection scope of the present invention can be more clearly defined.

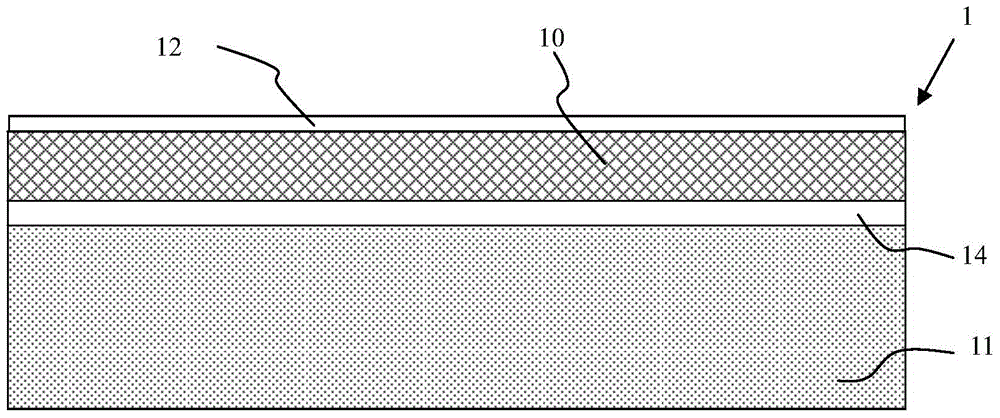

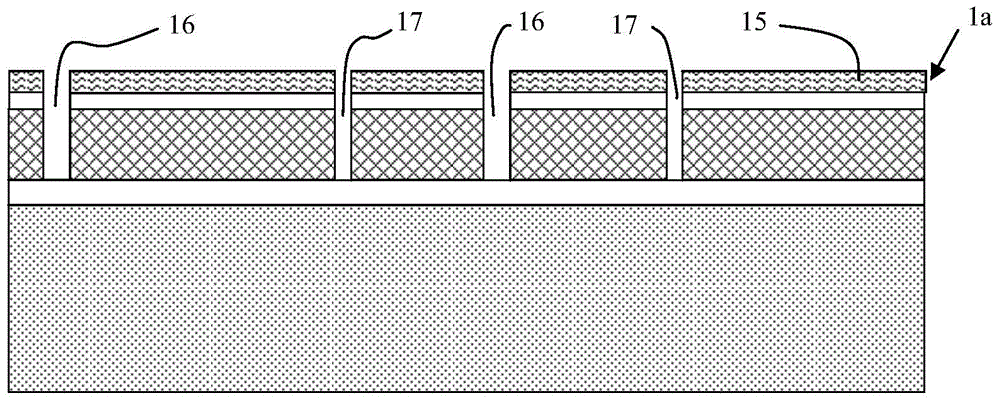

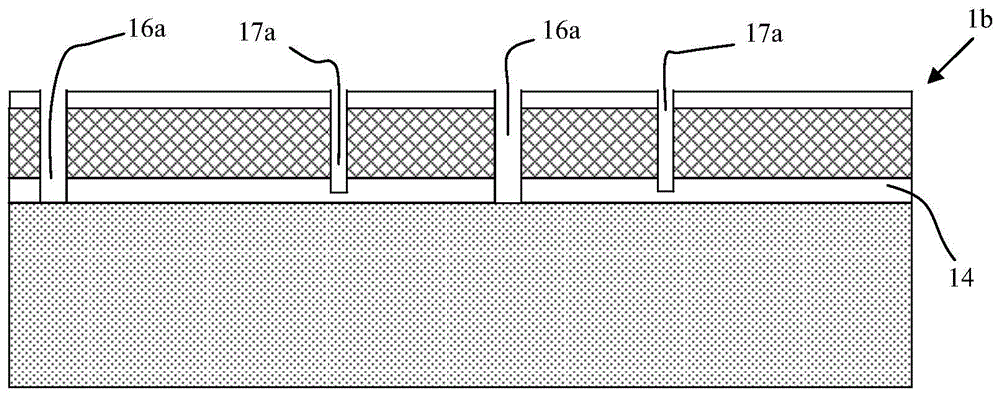

[0043] see figure 1 , the material of the top layer Si 10 of the SOI wafer 1 is heavily doped monocrystalline silicon with a crystal orientation, and a first oxide layer 12 is grown on the top layer Si 10 by general semiconductor processing technology, and its material is silicon dioxide , formed by thermal oxidation, the thickness of the top layer Si 10 is determined according to the thickness of the lower electrode of the MEMS chip, generally 5-60 microns; the material of the bottom layer Si 11 of the SOI wafer 1 is also a heavily doped monolayer with a crystal orientation. Crystalline silicon, its thickness is generally 300-800 microns; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com