Water-soluble compound nitrogen fertilizer and preparation method

A nitrogen fertilizer and water-soluble technology, applied in the direction of nitrogen fertilizer, fertilization equipment, fertilizer mixture, etc., can solve problems such as unfavorable operation, high concentration of 98%, easy to block pipes, and block equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

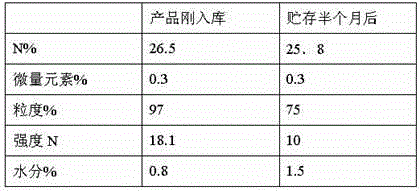

Embodiment 1

[0030] Take the current high-efficiency and low-consumption high-tower granulation as an example. The daily output is 1,000 tons. The ammonium nitrate device is concentrated to about 85% high-temperature ammonium nitrate solution. The temperature of the ammonium nitrate solution is 120°C. At the same time, after the ammonium sulfate is heated, it is transported and metered by a screw, and then added to the continuous mixing reactor. The mass ratio of ammonium sulfate to ammonium nitrate is 60:40, and the temperature of the continuous mixing reactor is controlled at 160°C for 10 minutes to promote the reaction of ammonium sulfate and ammonium nitrate to form a stable double salt of ammonium sulfur nitrate. Add 0.5% of the total mass of PH regulator sodium carbonate and 0.5% of the internal desiccant calcium nitrate into the continuous mixing tank with heating, further concentrate, control the water content of the slurry to ≤1%, and then granulate through a high tower to obtain s...

Embodiment 2

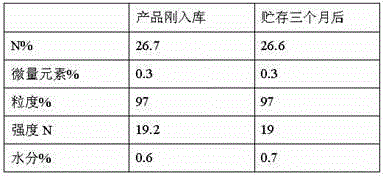

[0038] The ammonium nitrate plant is concentrated to about 95% high-temperature ammonium nitrate solution at a temperature of 170°C. After being transported and metered by pipeline, it is added to the continuous mixing reactor. . The mass ratio of ammonium sulfate to ammonium nitrate is 40:60, and the temperature of the continuous mixing reactor is controlled at 210°C for 3 minutes to promote the reaction of ammonium sulfate and ammonium nitrate to form a stable double salt of ammonium sulfur nitrate. Add 10% of the total mass of PH regulator sodium bicarbonate and 15% of the internal desiccant magnesium sulfate into the continuous mixing tank with heating, further concentrate, control the water content of the slurry to ≤1%, and then granulate through discs to obtain stable water-soluble compound nitrogen fertilizer.

[0039] The ammonium sulfate is ammonium sulfate solid or solution.

[0040] The ammonium sulfate is added into the reactor after preheating, and the temperatu...

Embodiment 3

[0042] The ammonium nitrate unit is concentrated to about 82% ammonium nitrate solution at room temperature, which is transported and metered through pipelines and fed into the continuous mixing reactor. The mass ratio of ammonium sulfate to ammonium nitrate is 51:49. The temperature of the continuous mixing reactor is controlled at 210°C for 3 minutes to promote the reaction of ammonium sulfate and ammonium nitrate to form a stable double salt of ammonium sulfur nitrate. Put the reacted ammonium sulfur nitrate double salt into the mixing tank, then add 10% of the pH regulator sodium bicarbonate of the total mass, and 15% of the internal desiccant magnesium sulfate into the mixing tank, further concentrate, and control the water content of the slurry. ≤1%, and then granulated by disk to obtain stable water-soluble compound nitrogen fertilizer. Wherein ammonium sulfate can be ammonium sulfate solid or solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com