Method for preparing gossypol acetate based on solid phase synthesis

A technology of gossypol acetate and solid-phase synthesis, which is applied in the chemical field, can solve problems such as toxic residues and affecting applications, and achieve the effects of low cost, reduced usage, and high extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

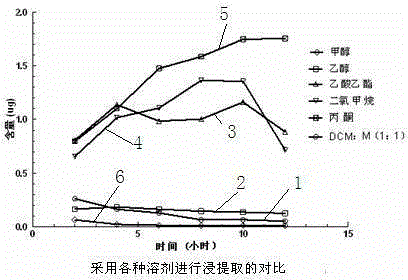

[0028] Weigh 20 g of cottonseed powder, wrap it in a filter paper tube, place it in a Soxhlet extractor, and add 150 mL of acetone to reflux for extraction for 12 h. Add 20 g of treated D380 amino resin to the extract, and stir for 4 h at room temperature. After the reaction was completed, suction filtered, and the amino resin bonded with gossypol was washed several times with petroleum ether and distilled water, then the resin was transferred to a 250 mL flat-bottomed flask, and a mixture of 60 mL of acetone and glacial acetic acid at a volume ratio of 1:1 was added. Turn on the magnetic stirring, slowly add 5 mL of sulfuric acid with a mass fraction of 9% with a dropping funnel, and stir at room temperature for 24 h. Suction filtration under reduced pressure, and the filtrate was concentrated to 20 mL at 55°C under reduced pressure, and then placed in the refrigerator overnight, and gossypol acetate solids were precipitated, filtered by suction, washed with petroleum ether a...

Embodiment 2

[0030] Weigh 20 g of cottonseed powder, wrap it in a filter paper tube, place it in a Soxhlet extractor, and add 150 mL of acetone to reflux for extraction for 12 h. Add 20 g of treated D392 amino resin to the extract, and stir for 4 h at room temperature. After the reaction, the amino resin bound to gossypol was washed with petroleum ether and distilled water for several times, then transferred to a 250 mL flat-bottomed flask, and 60 mL of a mixture of acetone and glacial acetic acid (volume ratio 1:1 ), turn on the magnetic stirring, slowly add 5 mL of sulfuric acid with a mass fraction of 9% using a dropping funnel, and stir at room temperature for 24 h. Suction filtration under reduced pressure, the filtrate was concentrated under reduced pressure at 55 °C to 20 mL, and then placed in the refrigerator overnight, gossypol acetate solids were precipitated, filtered by suction, washed with petroleum ether and distilled water in sequence, and dried to obtain 155 mg gossypol ac...

Embodiment 3

[0032] Weigh 20 g of cottonseed powder, wrap it in a filter paper tube, place it in a Soxhlet extractor, and add 150 mL of ethyl acetate to reflux for extraction for 12 h. Add 20 g of treated D380 amino resin to the extract, and stir for 4 h at room temperature. After the reaction, the amino resin bound to gossypol was washed with petroleum ether and distilled water for several times, then transferred to a 250 mL flat-bottomed flask, and 60 mL of a mixture of acetone and glacial acetic acid (volume ratio 1:1 ), turn on the magnetic stirring, slowly add 5 mL of sulfuric acid with a mass fraction of 9% using a dropping funnel, and stir at room temperature for 24 h. Suction filtration under reduced pressure, the filtrate was concentrated to 20 mL under reduced pressure at 55 °C, and then placed in the refrigerator overnight, gossypol acetate solids were precipitated, filtered by suction, washed with petroleum ether and distilled water in sequence, and dried to obtain 117 mg gossy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com