Non-enzymic glucose sensor of modified nanometer copper oxide screen-printed electrode

A technology of glucose sensor and screen printing electrode, which is applied in the field of preparation of non-enzyme glucose sensor, can solve the problems of cumbersome production and achieve the effects of low preparation cost, good stability and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] A kind of non-enzyme glucose sensor of nano copper oxide modified screen printing electrode, its preparation method steps are as follows:

[0033] 1) Preparation of copper sulfate-cetyltrimethylammonium bromide mixed solution

[0034] Dissolve 2g of copper sulfate in 30mL of deionized water, stir at room temperature for 10min, then add 0.1g of cetyltrimethylammonium bromide (CTAB), and stir magnetically for 30min to obtain copper sulfate-cetyltrimethylammonium bromide mixture;

[0035] 2) Preparation of copper oxide

[0036] In the above copper sulfate-hexadecyltrimethylammonium ammonium bromide mixed solution, add 70mL of NaOH solution with a concentration of 8mol / L dropwise with a separatory funnel, stir for 36h, and vacuum filter to obtain a black precipitate. Heating at 60°C for 1.5h, and grinding to obtain copper oxide;

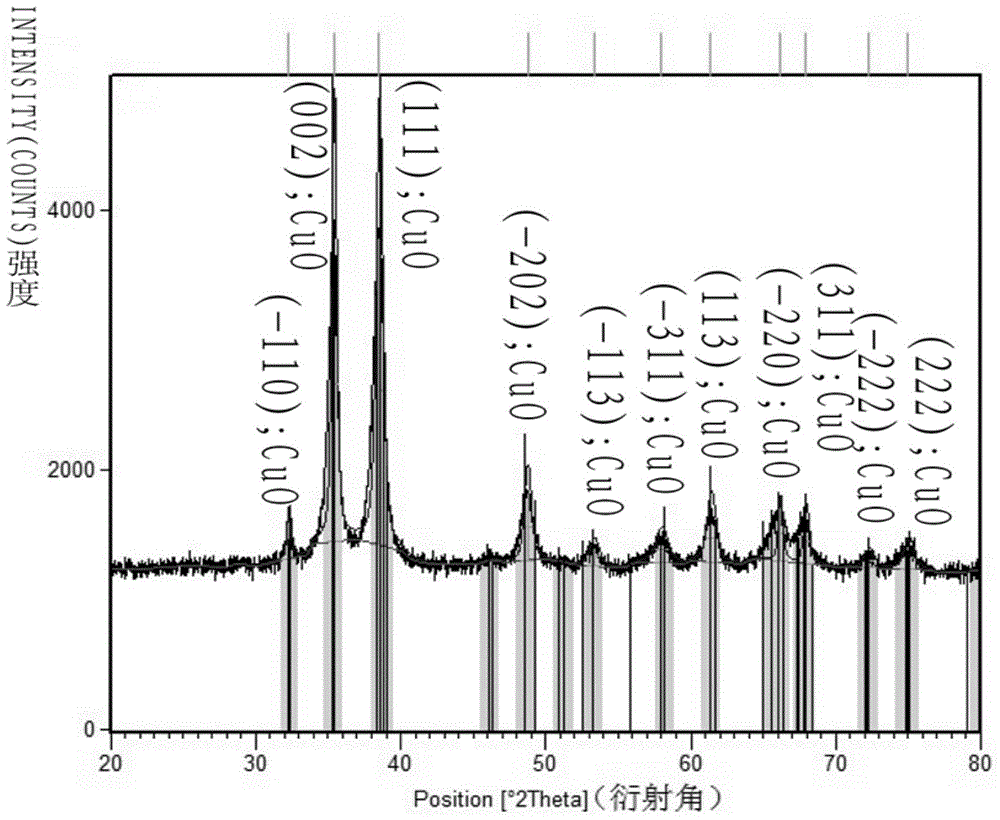

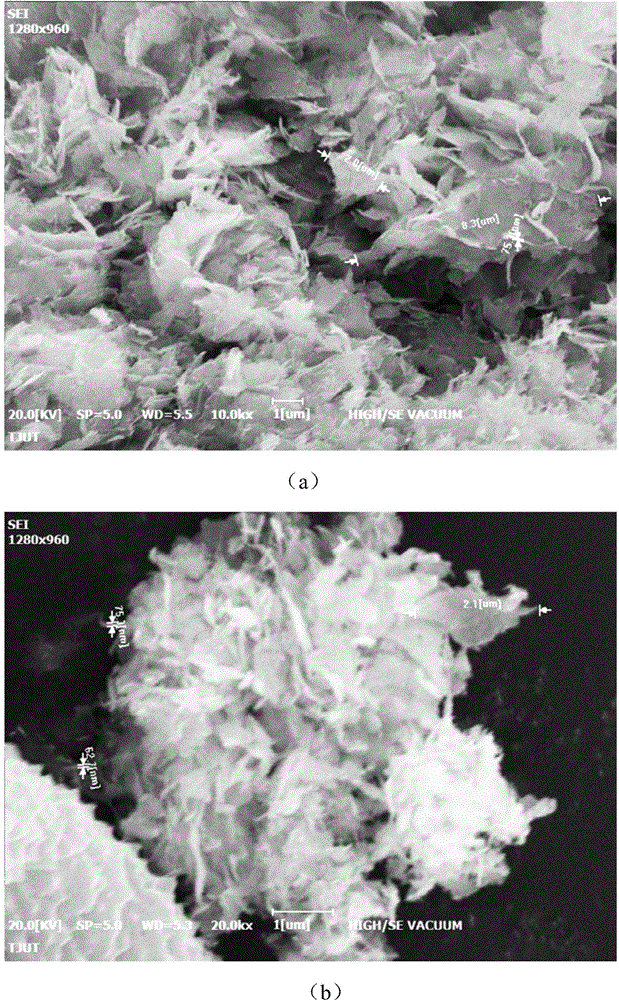

[0037] figure 1 It is the X-ray powder diffraction pattern of the prepared copper oxide product, which shows that the main component of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com