Device and method for preparing long-periodic fiber bragg grating by femtosecond laser Talbot effect

A technology of femtosecond laser and fiber grating, which is applied in the direction of cladding optical fiber, optical waveguide, light guide, etc., can solve the problem of low utilization efficiency of femtosecond laser, achieve the effect of reducing production cost, reducing processing time and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

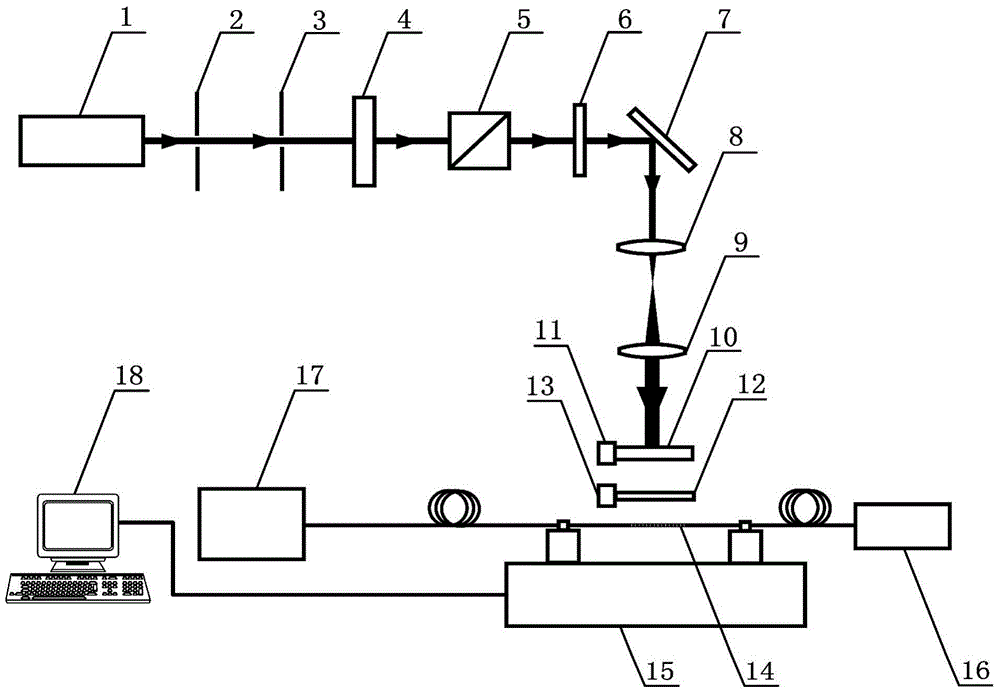

[0037] Embodiment 1 of the present invention such as figure 1 As shown, a device for fabricating long-period fiber gratings using the femtosecond laser Taber effect, the device includes a femtosecond laser light source 1, a first collimating diaphragm 2, a second collimating diaphragm 3, and an achromatic 1 / 2 A wave plate 4, a polarizing beamsplitter prism 5, a shutter 6, a mirror 7, a first convex lens 8, a second convex lens 9, a cylindrical lens 10, a first precision moving platform 11, a phase grating 12, a second precision moving platform 13, Optical fiber 14 to be processed, electronically controlled three-dimensional precision mobile platform 15, broadband light source 16, spectrometer 17, computer 18; it is characterized in that the femtosecond laser light source 1 is located before the first collimation diaphragm 2, and the sequence after the first collimation diaphragm 2 Place the second collimating diaphragm 3, the achromatic half-wave plate 4, the polarizing beam s...

Embodiment 2

[0047] A method for preparing a long-period fiber grating by using the above-mentioned device, the steps are as follows:

[0048] (1) each optical device in the above-mentioned device is built up the optical path according to the optical path sequence;

[0049] (2) Turn on the femtosecond laser source, adjust the pump light power of the femtosecond laser source amplification stage and the fast axis orientation of the achromatic half-wave plate, measure the femtosecond laser power with an optical power meter, and make the output from the polarization beam splitter prism The femtosecond laser power is 1.0 mW;

[0050] (3) Open the shutter, use the first collimation diaphragm and the second collimation diaphragm to adjust the position of each optical device in the optical path, so that the femtosecond laser passes through the achromatic 1 / 2 wave plate, polarization beam splitter prism, shutter, mirror , the first convex lens, the second convex lens, the cylindrical lens and the ...

Embodiment 3

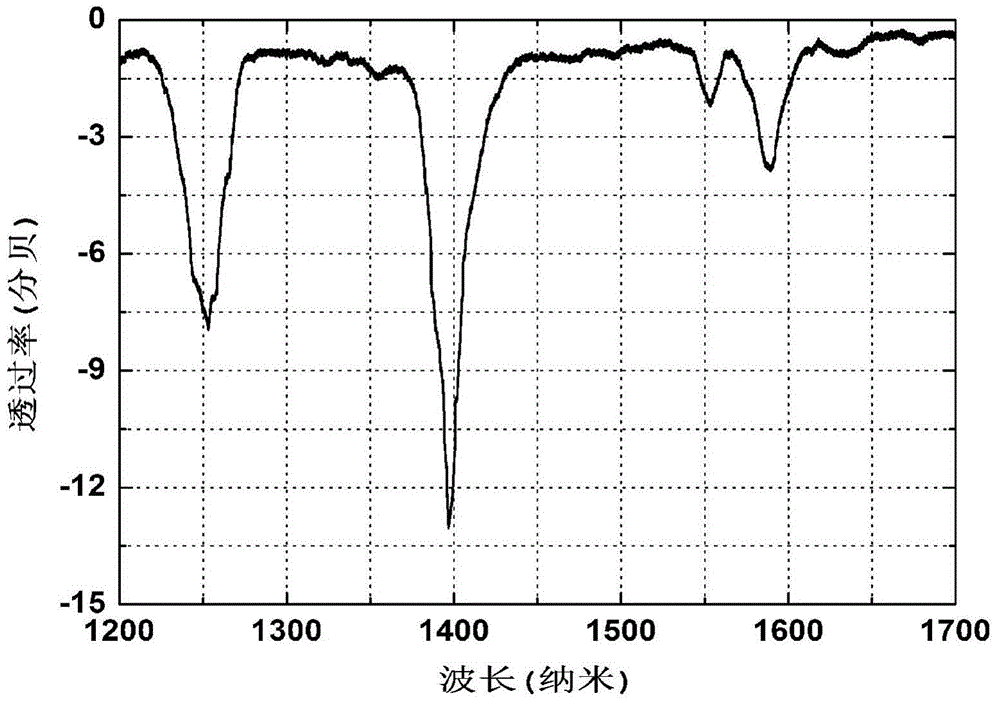

[0058] Identical with embodiment 2 steps, just use cycle is 200 μ m in step (4), aperture ratio is 1 / 3, the one-dimensional pure phase grating that phase modulation is 2π / 3; The femtosecond laser power emitted by the polarization beam splitter prism is 1.4 watts; after the shutter is opened in step (8), the irradiation time of the femtosecond laser grating to be processed is 25 seconds to obtain a long-period fiber grating, image 3 The prepared long-period fiber grating transmission spectrum distribution curve, the highest resonance peak peak depth is -13.9dB.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com