A transistor based on an enhanced gate structure and its preparation method

A gate structure, enhanced technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of insufficient stability of components, complex manufacturing process, high process requirements, etc., to reduce spontaneous thermal effects, Simple process and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

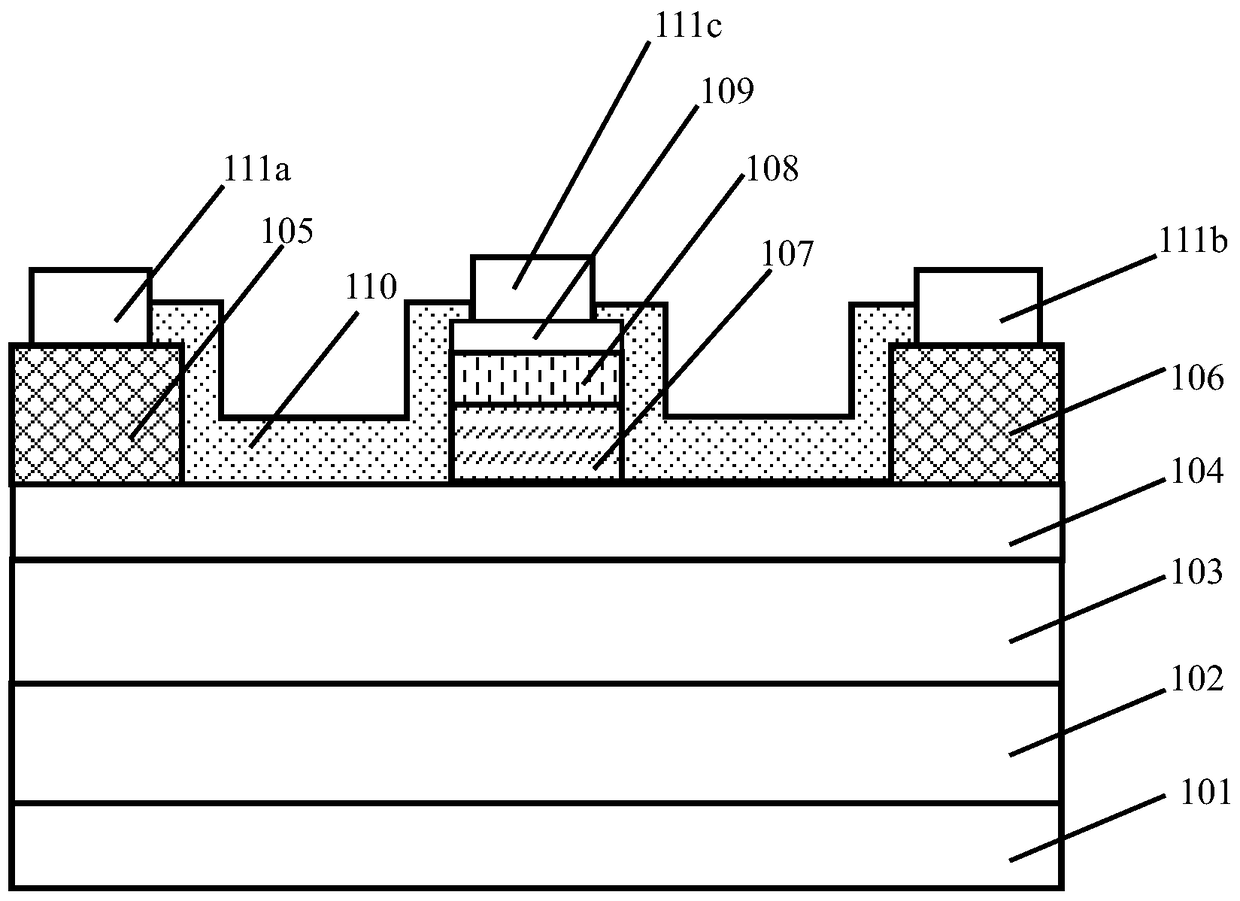

[0037] refer to figure 1 , the transistor 100 of this embodiment has a substrate 101, a buffer layer 102, a gallium nitride layer 103, and a barrier layer 104 stacked sequentially from bottom to top, and the upper surface of the barrier layer 104 is provided with a source 105, a drain 106, and The gate 107 located between the two has a DLC layer 108 and a metal electrode layer 109 stacked on top of the gate 107 in sequence. A passivation layer 110 is covered on the above structure, and the passivation layer 110 is respectively provided with openings above the source electrode 105, the drain electrode 106 and the metal electrode layer 109, and thickened electrodes 111a, 111b and 111c are respectively provided in the openings .

[0038] The barrier layer 104 is AlGaN; the gate 107 is p-type Al 1-x Ga x N, where 0≤x≤1. AlGaN and Al 1-x Ga x The p-n contact surface is formed between N, and its potential barrier is higher than that caused by ordinary Schottky contact (metal g...

Embodiment 2

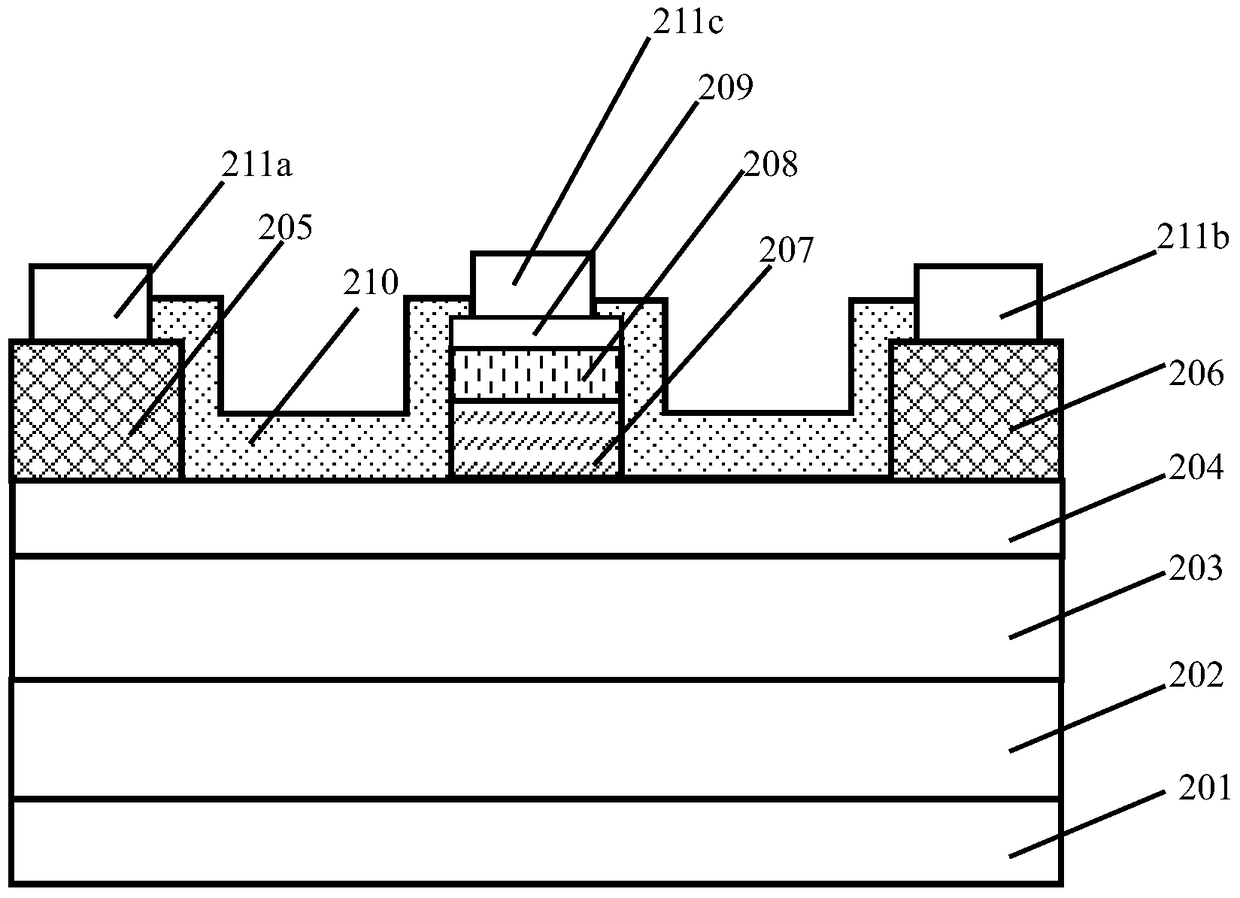

[0051] refer to figure 2 , the transistor 200 of this embodiment has a substrate 201, a buffer layer 202, a gallium nitride layer 203, and a barrier layer 204 stacked sequentially from bottom to top, and the upper surface of the barrier layer 204 is provided with a source 205, a drain 206, and The gate 207 located between the two has a DLC layer 208 and a metal electrode layer 209 stacked on top of the gate 207 in sequence. The passivation layer 210 is covered on the above structure, and the passivation layer 210 is respectively provided with openings above the source electrode 205, the drain electrode 206 and the metal electrode layer 209, and thickened electrodes 211a, 211b and 211c are respectively provided in the openings. .

[0052] The barrier layer 204 is InAlGaN; the gate 207 is p-type In 1-y-z Ga y Al z N, where 0≤y≤1; 0≤z≤1. InAlGaN and In 1-y-z Ga y Al z The p-n contact surface is formed between N, and its potential barrier is higher than that caused by ord...

Embodiment 3

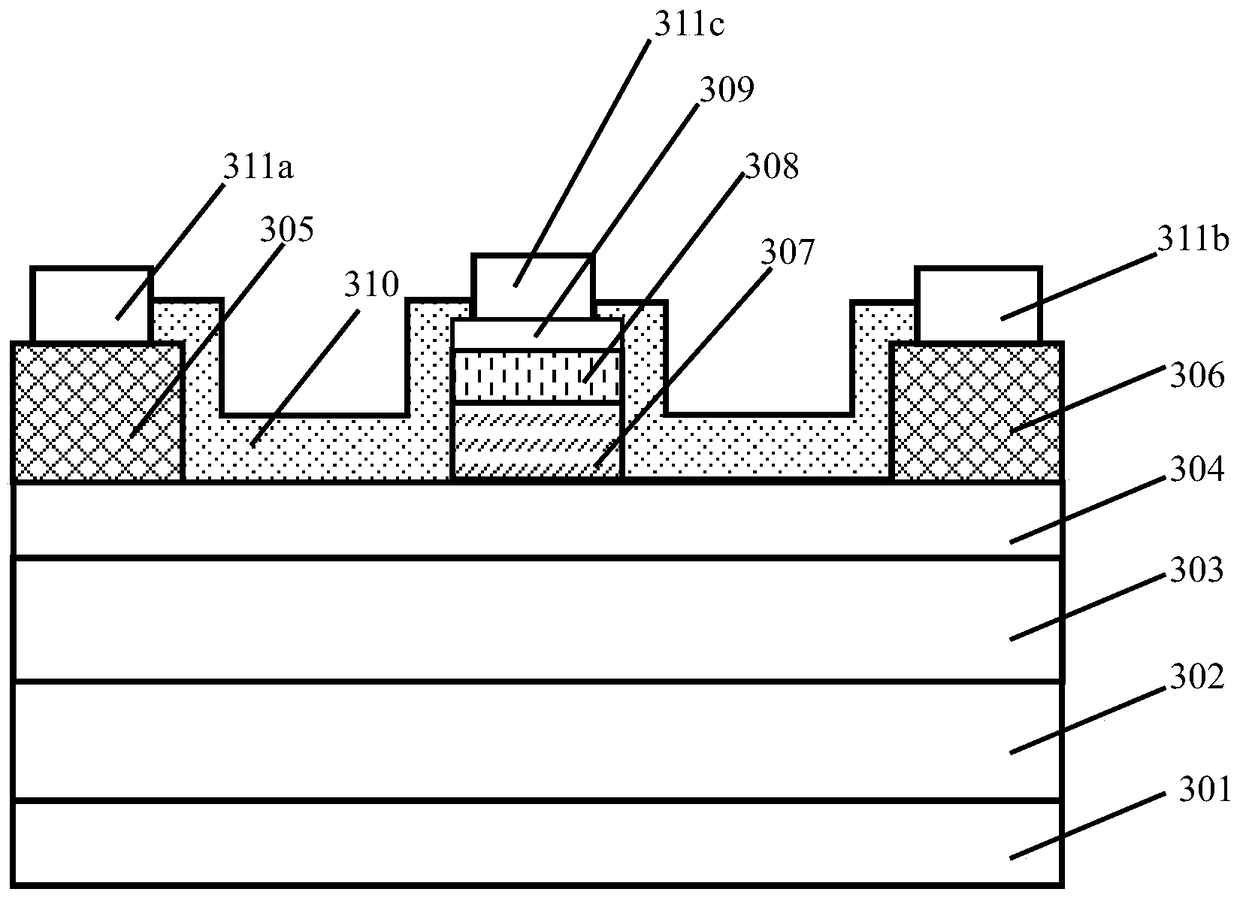

[0055] refer to image 3 , the transistor 300 of this embodiment has a substrate 301, a buffer layer 302, a gallium nitride layer 303 and a barrier layer 304 stacked in sequence from bottom to top, and a source 305, a drain 306 and a source 305 are arranged on the upper surface of the barrier layer 304. The gate 307 located between the two has a DLC layer 308 and a metal electrode layer 309 stacked on top of the gate 307 in sequence. A passivation layer 310 is covered on the above structure, and the passivation layer 310 is respectively provided with openings above the source electrode 305, the drain electrode 306 and the metal electrode layer 309, and thickened electrodes 311a, 311b and 311c are respectively provided in the openings. .

[0056] In this embodiment, the DLC layer 308 is p-type doped DLC, the content of sp2 bonds is greater than 50%, and doped with less than 5wt% of boron (B), aluminum (Al), indium (In) or a combination thereof. The materials of other compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com