Artificial microalgae strain breeding method

A technology for microalgae algae and algae strains is applied in the field of artificial breeding of microalgae algae strains, which can solve the problems of long time and achieve the effects of short processing time, avoiding toxicity or strong cell damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

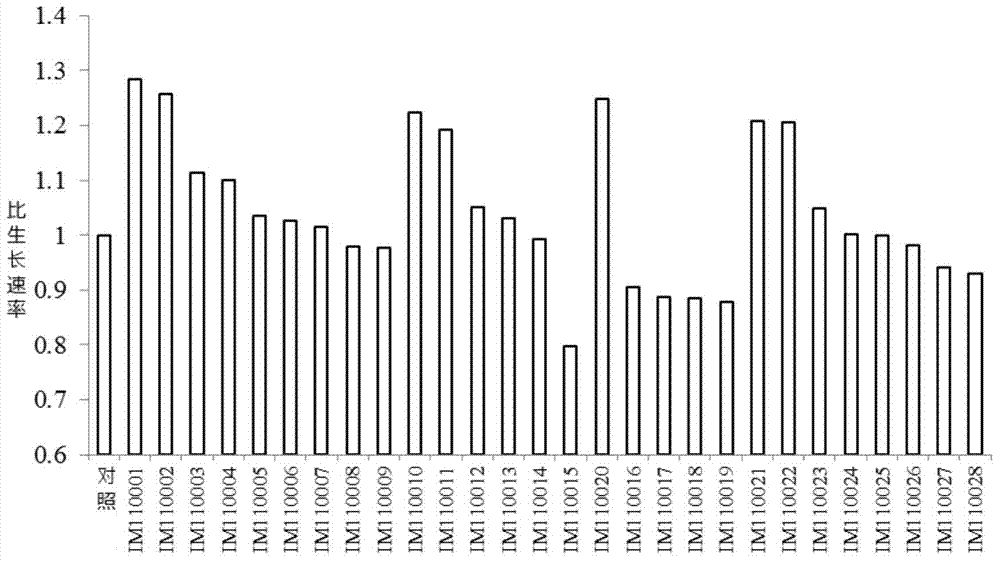

[0021] Taking Isochrysis zhangjiangensis FACHB-1750, preserved in the Algal Species Preservation Center of Wuhan Institute of Hydrobiology, Chinese Academy of Sciences as the object, the Atmospheric Room Temperature Plasma Breeding Machine (ARTP) jointly developed by the Department of Chemical Engineering and Engineering Physics of Tsinghua University was used. ) for mutagenesis of golden algae.

[0022] 1. Adjust the concentration of the Zhanjiang Isoflagellate culture solution to 1-10 million cells / ml, and take 10-200 microliters of the algae solution and put it on the slide.

[0023] 2. Place the slide on the stage, and adjust the distance between the jet outlet and the slide to be less than or equal to 10mm.

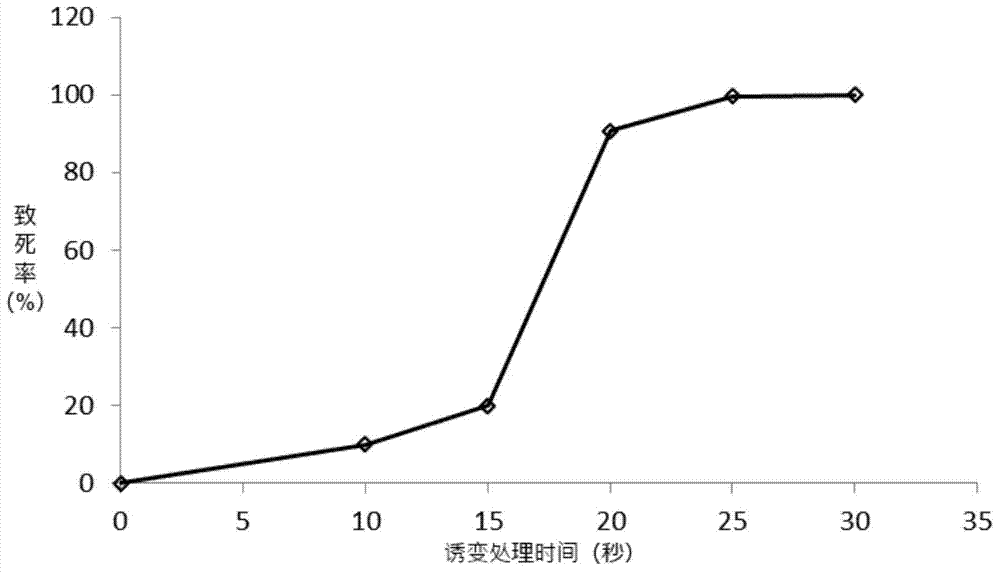

[0024] 3. The output power of the power supply is 50-200W, the working air flow is 1-20SLM, and the discharge time is 5 seconds to 2 minutes.

[0025] 4. Rinse the slide with 800 microliters of golden algae culture solution (natural seawater + F / 2 medium), and recov...

Embodiment 2

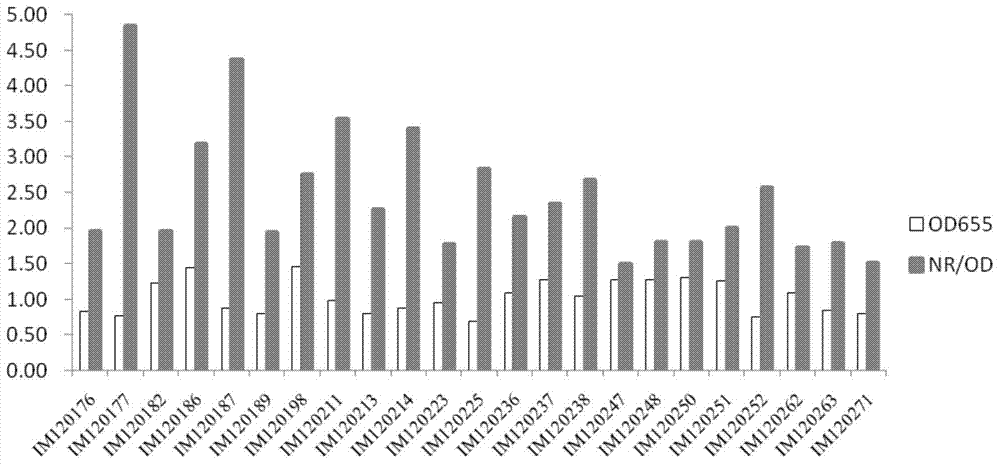

[0032] The mutagenesis and other operations are the same as in Example 1, and the screening is carried out with the goal of high temperature resistance, and the coated plates after the mutagenesis are placed at 36°C for cultivation; the light intensity is 30-50 μmol·m -2 ·s -1 , the light-to-dark ratio is 14:10.

[0033] Finally, 9 algae strains with high temperature resistance and high oil content were obtained, and the control was the wild strain under normal culture conditions.

Embodiment 3

[0035] High-yield starch-yielding marine green alga Tetraselmis subcordiformis FACHB-1751, preserved in the Algae Collection Center of Wuhan Institute of Hydrobiology, Chinese Academy of Sciences) strain selection. The mutagenesis was carried out with 1.5 million cells / ml of Tetraspermum algae, the distance between the plasma emission source and the sample was 2mm, the culture medium was natural seawater + Conway nutrient salt, and the mutagenesis time was 30s. After the mutagenesis, dilute the algae solution of Tetragalus 10,000 times, and apply it to the solid plate of Kangweifang. Other operations are the same as in Example 1.

[0036] After mutagenesis, the lethal rate was 99.6%. The starch content of the mutagenized algae strains was investigated by the color value of iodine staining.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com