High temperature oxidation and heat resistant copper-nickel-based alloy

A high-temperature oxidation-resistant, nickel-based alloy technology, applied in the field of high-temperature oxidation-resistant copper-nickel-based alloys, can solve the problems of thermal conductivity, casting and hot forming process performance, poor machinability, and easy oxidation, etc., to achieve excellent high temperature resistance Oxidation properties, the effect of overcoming poor thermal conductivity, and good high-temperature thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

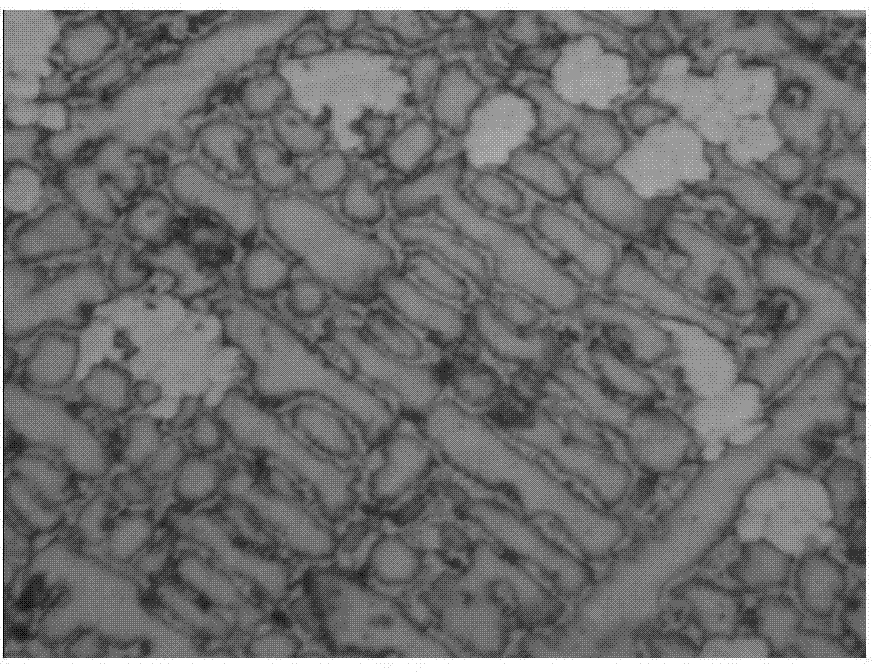

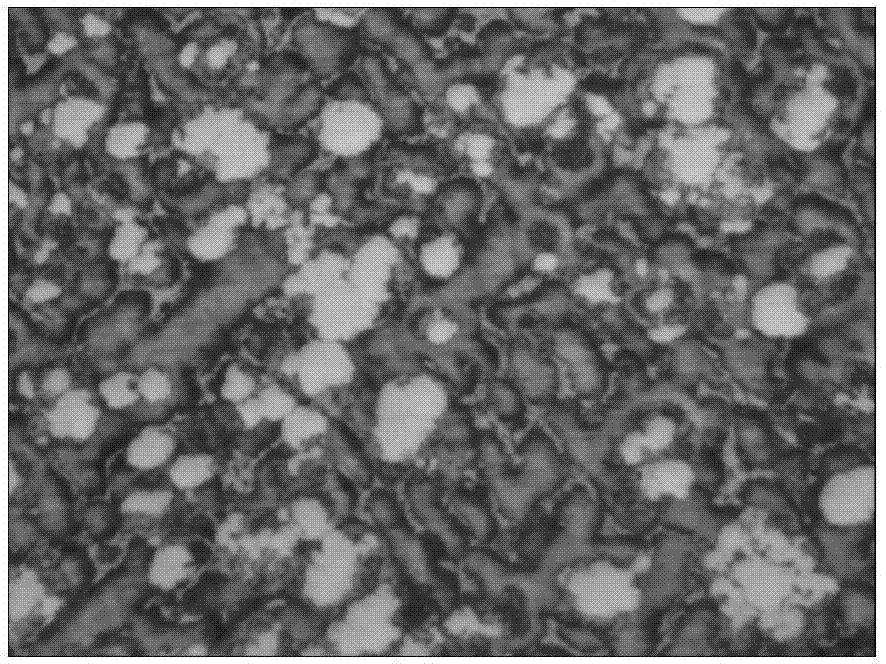

[0047] The raw materials are mixed according to mass percentage: Ni 28%, Al 8%, Cr 3%, Zr 2%, Si 1%, Ce 0.4%, and the balance is Cu, and are melted in a vacuum induction furnace. The melting temperature is 1320° C., and the temperature is kept for 10 minutes. Then, the alloy liquid with a pouring temperature of 1250° C. was poured into a steel mold with a diameter of 30 mm, and cooled naturally to obtain a circular ingot with a diameter of 30 mm. The microstructure of the alloy casting is composed of a large amount of α-Cu solid solution phase, a certain amount of β-Cr-rich phase and NiAl phase. The size is relatively large. The microhardness, tensile strength and elongation values are shown in Table 2. The high temperature oxidation gain is shown in Table 3.

Embodiment 2

[0049] The raw materials are mixed according to mass percentage: Ni 29%, Al 8.5%, Cr 3.5%, Zr 2%, Si 1%, Ce 0.5%, and the balance is Cu, and are melted in a vacuum induction furnace. The melting temperature is 1325° C., and the temperature is kept for 10 minutes. Then, the alloy liquid with a pouring temperature of 1255° C. was poured into a steel mold with a diameter of 30 mm, and cooled naturally to obtain a circular ingot with a diameter of 30 mm. The microstructure of the alloy casting is composed of a large amount of α-Cu solid solution phase, a certain amount of β-Cr-rich phase and NiAl phase. The size is relatively large. See Table 2 for its microhardness, tensile strength and elongation; see Table 3 for its high-temperature oxidation gain.

Embodiment 3

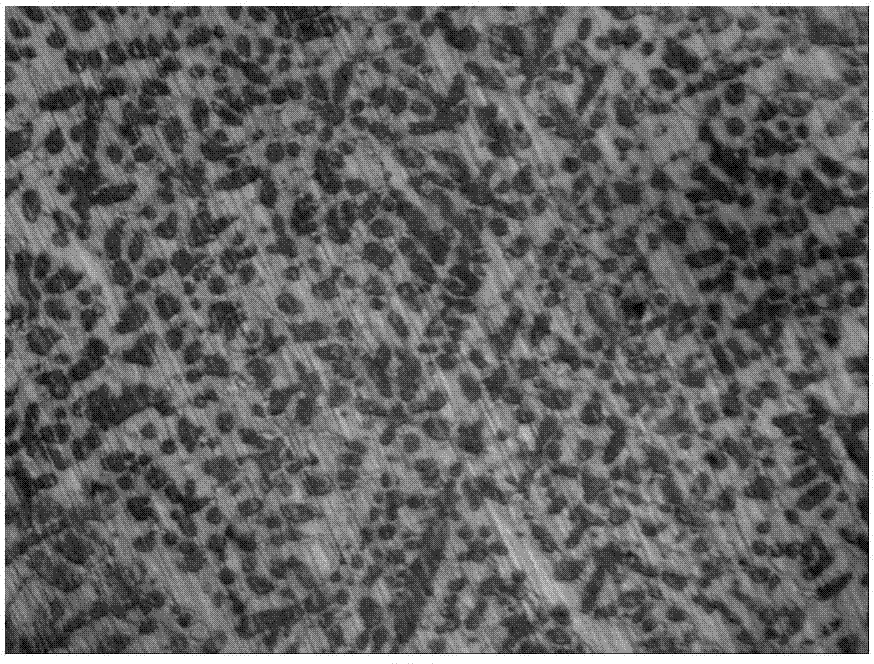

[0051] The raw materials are mixed according to mass percentage: Ni 30%, Al 9%, Cr 4%, Zr 2.5%, Si 1.5%, Ce 0.6%, and the balance is Cu, and are melted in a vacuum induction furnace. The melting temperature is 1325°C and the temperature is kept for 12 minutes. Then, the alloy liquid with a pouring temperature of 1260° C. was poured into a steel mold with a diameter of 30 mm, and cooled naturally to obtain a circular ingot with a diameter of 30 mm. The microstructure of the alloy casting is composed of fine α-Cu solid solution phase, a small amount of β-Cr-rich phase and NiAl phase. See Table 2 for its microhardness, tensile strength and elongation; see Table 3 for its high-temperature oxidation gain.

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com