A kind of manufacturing method of positive electrode of lithium-sulfur battery

A manufacturing method and lithium-sulfur battery technology, applied in battery electrodes, positive electrodes, active material electrodes, etc., can solve the problems of poor electrical conductivity of elemental sulfur, achieve a large reactive surface, improve electrochemical performance, reduce impedance and polarity degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

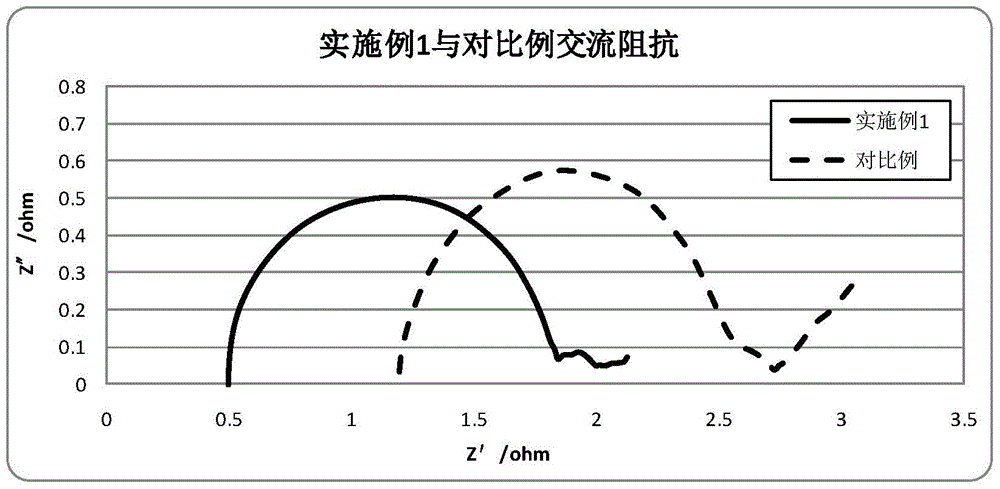

Embodiment 1

[0045] 1) Collector treatment

[0046] Put the aluminum foil (20μm) used as the positive electrode collector of the lithium-sulfur battery into 5% oxalic acid solution, corrode for 1min, take it out and immerse it in deionized water, ultrasonic for 10s, and air dry for later use;

[0047] Mix water and ethanol at a volume ratio of 1:9 to prepare a mixed solution, mix superP and AB at a mass ratio of 1:1 and dissolve in the mixed solution of water and ethanol, with a mass fraction of 0.5%, ultrasonication for 20 minutes; select PTFE with a solid content of 60% Emulsion, according to the mass ratio of carbon material: PTFE (solid) 80%: 20%, add PTFE emulsion, mix thoroughly, ultrasonic 30min, wait until the mixture is uniform, and set aside;

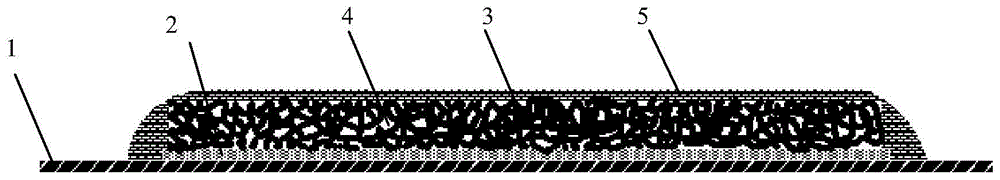

[0048] Spread the treated aluminum foil on an 80°C heating plate, and spray the ultrasonically uniform mixture onto one or both sides of the aluminum foil, with the carbon material loading controlled at 0.2mg / cm 2 , dried, and rolled by a...

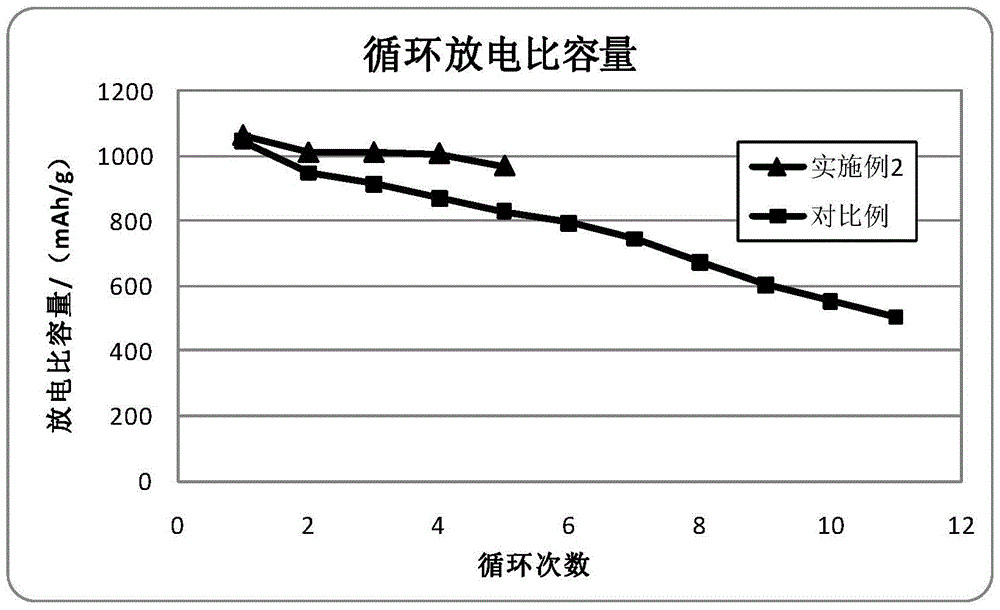

Embodiment 2

[0057] 1) Collector treatment

[0058] Put the aluminum foil (20μm) used as the positive electrode collector of the lithium-sulfur battery into a 5% oxalic acid solution, corrode for 1min, take it out, immerse it in deionized water, ultrasonicate for 10s, and air-dry it for later use;

[0059] Mix water and ethanol at a volume ratio of 1:9 to prepare a mixed solution, mix superP and AB at a mass ratio of 1:1 and dissolve in the mixed solution of water and ethanol, with a mass fraction of 0.5%, ultrasonication for 20 minutes; select PTFE with a solid content of 60% Emulsion, according to the mass ratio of carbon material: PTFE (solid) 80%: 20%, add PTFE emulsion, mix thoroughly, ultrasonic 30min, wait until the mixture is uniform, and set aside;

[0060] Spread the treated aluminum foil on an 80°C heating plate, and spray the ultrasonically uniform mixture onto one or both sides of the aluminum foil, with the carbon material loading controlled at 0.2mg / cm 2 , dried, and rolled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com