Hypoallergenic milk protein powder and preparation method thereof

A milk protein powder, hypoallergenic technology, applied in protein food processing, animal protein processing, protein food ingredients, etc., can solve problems such as patents or literature reports on the method for reducing casein allergy, and achieve good flavor , improve the degree of reduction, improve the effect of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

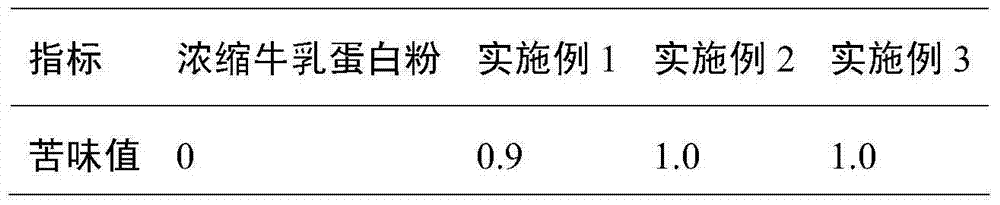

Embodiment 1

[0047] Example 1 Preparation method of hypoallergenic milk protein powder (1)

[0048] (1) Take 10 grams of concentrated milk protein powder (protein 67.2%, lactose 17.8%, fat 1.6%, moisture 4.8%), add 115 grams of water, so that the milk protein powder accounts for 8% of the mass percentage of the mixture. Hydrate for 120 min at 40°C, stir and dissolve it thoroughly to obtain a milk protein solution. Put the milk protein solution in an ultrasonic generator and treat it with ultrasonic (frequency 25kH) for 30 minutes;

[0049] (2) Add 0.1 g of compound protease (flavor protease: alkaline protease: neutral protease) to the milk protein solution after ultrasonic treatment in step (1) according to the weight percentage of 1% of the weight of the protein powder in the milk protein solution. The mass ratio is 3:2:1). Enzymatic hydrolysis is carried out at 50°C and pH 7.5 for 120 minutes; then it is kept at 95°C for 3 minutes and cooled to room temperature to obtain the lactolysis solut...

Embodiment 2

[0052] Example 2 Preparation method of hypoallergenic milk protein powder (2)

[0053] (1) Take 50 grams of concentrated milk protein powder (protein 67.2%, lactose 17.8%, fat 1.6%, moisture 4.8%), add 450 grams of water, so that the milk protein powder accounts for 10% of the mass percentage of the mixture. Hydrate for 120 min at 40°C, stir and dissolve it thoroughly to obtain a milk protein solution. Put the milk protein solution in an ultrasonic generator and treat it with ultrasonic (frequency 20kH) for 20 minutes;

[0054] (2) Add 0.6 grams of compound protease (flavor protease: alkaline protease: neutral protease) to the milk protein solution after ultrasonic treatment in step (1) at a weight percentage of 1.2% of the weight of the protein powder in the milk protein solution The mass ratio is 3:2:1), enzymatic hydrolysis is carried out at 45°C and pH 7.5 for 80 minutes; then it is kept at 95°C for 3 minutes and cooled to room temperature to obtain the lactolysis solution;

[...

Embodiment 3

[0057] Example 3 Preparation method of hypoallergenic milk protein powder (3)

[0058] (1) Take 100 grams of concentrated milk protein powder (protein 67.2%, lactose 17.8%, fat 1.6%, moisture 4.8%), add 900 grams of water, so that the milk protein powder accounts for 10% of the mass percentage of the mixture. Hydrate for 90 min at 35°C, stir and dissolve it thoroughly to obtain a milk protein solution. Put the milk protein solution in an ultrasonic generator and treat it with ultrasonic (frequency 25kH) for 30 minutes;

[0059] (2) Add 1.0 g of composite protease (flavor protease: alkaline protease: neutral protease) to the milk protein solution after ultrasonic treatment in step (1) according to the weight percentage of 1% of the weight of the protein powder in the milk protein solution. The mass ratio is 3:2:1). Enzymatic hydrolysis is carried out at 55°C and pH 7.0 for 100 minutes; then it is kept at 95°C for 3 minutes and cooled to room temperature to obtain the lactoprotein h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com