PMX‑53 gelatin composite particles and preparation method thereof

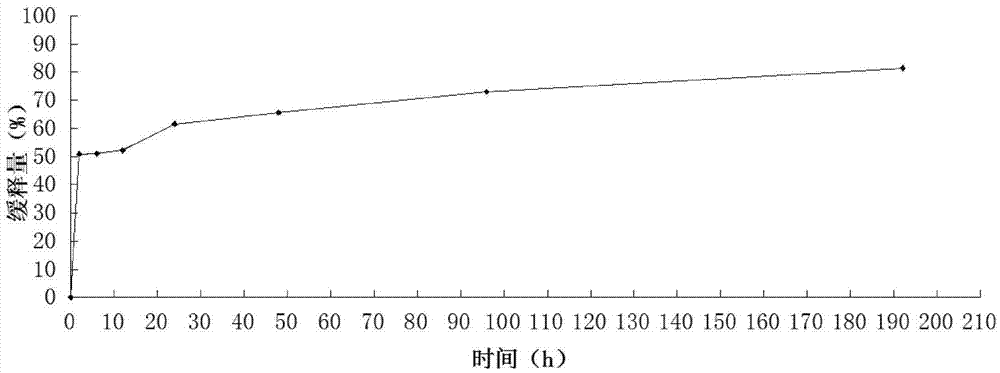

A technology of PMX-53 and composite particles, which is applied in the direction of drug combinations, pharmaceutical formulas, and non-effective ingredients of polymer compounds, can solve the problems of large dosage, difficulty in maintaining drug concentration, and low bioavailability, so as to reduce drug administration The effect of increasing the number of times, improving bioavailability, and maintaining drug concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

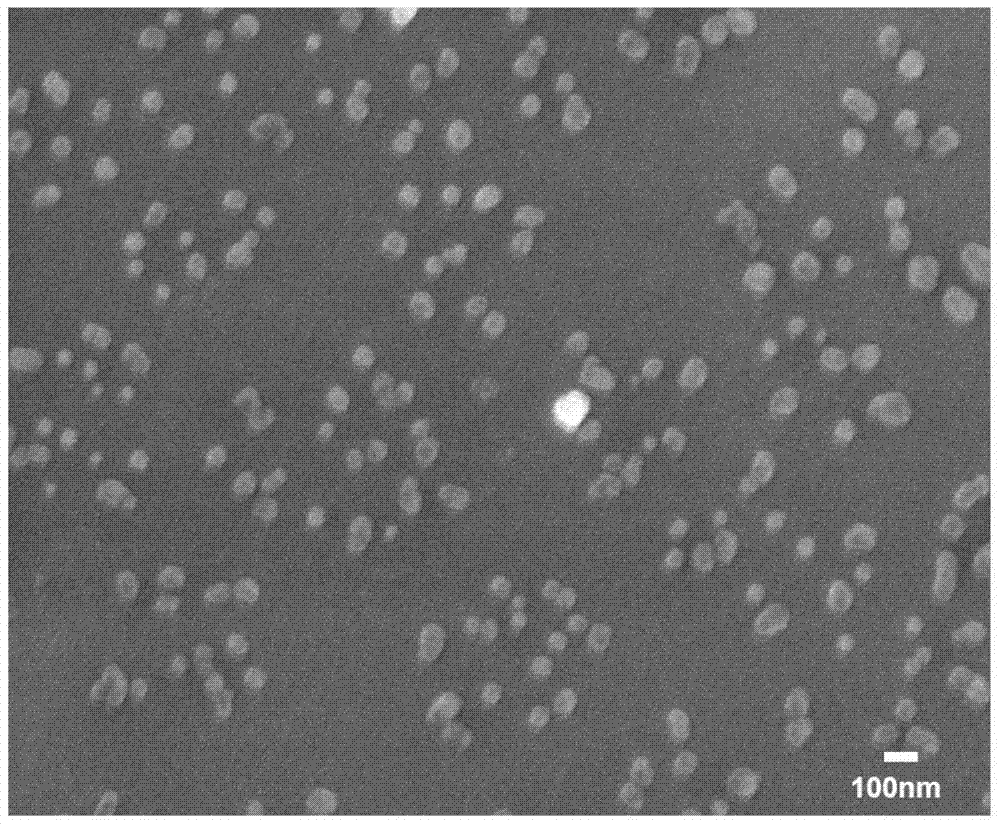

[0026] Take 500mg of type A gelatin (with an isoelectric point of 7-9) and add it to 10mL of deionized water, heat-dissolve at 60°C to form an aqueous gelatin solution, add 10mL of acetone to the aqueous gelatin solution, remove the upper suspension, and obtain 200mg of precipitated gelatin. Dissolve the precipitated gelatin again in 10 mL of deionized water, adjust the pH value of the reaction system to 7.0 with aqueous hydrochloric acid and sodium hydroxide solution, add 2 mg of PMX-53 to the aqueous gelatin solution, and stir magnetically at 800rmp / min for 3min; under magnetic stirring at 1500rmp / min Add 40 mL of acetone to the above system to emulsify the system to form gelatin particles, add 200 μL of 50% glutaraldehyde aqueous solution, and stir in an ice bath for 6 hours to solidify the gelatin particles; centrifuge at 15000 rpm, remove the supernatant, and use acetone under ultrasonic The precipitate was washed 4 times, and vacuum-dried to obtain PMX-53-loaded gelatin c...

Embodiment 2

[0028] Take 1000mg type A gelatin (isoelectric point is 7~9) and add it into 10mL deionized water, heat-dissolve at 60°C to form a gelatin aqueous solution, add 10mL acetone to the gelatin aqueous solution, remove the upper suspension, take 800mg of precipitated gelatin, and use Dissolve the precipitated gelatin again with 10 mL of deionized water, adjust the pH value of the reaction system to 8.0 with hydrochloric acid and sodium hydroxide aqueous solution, add 1 mg of PMX-53 to the gelatin aqueous solution, and stir magnetically at 800rmp for 3min; Emulsify the system into the above system to form gelatin particles, add 500 μL of glutaraldehyde aqueous solution with a mass fraction of 50%, and stir in an ice bath for 6 hours to solidify the gelatin particles; centrifuge at 15,000 rpm, remove the supernatant, and wash the precipitate with acetone under ultrasound for 4 times , vacuum-dried to obtain PMX-53-loaded gelatin composite microparticles, detected by a scanning electro...

Embodiment 3

[0030] Take 800mg of type A gelatin (with an isoelectric point of 7-9) and add it to 10mL of deionized water, heat-dissolve it at 60°C to form an aqueous gelatin solution, add 10mL of acetone to the aqueous gelatin solution, remove the upper suspension, and obtain 400mg of precipitated gelatin. Dissolve the precipitated gelatin again in 10mL of deionized water, adjust the pH value of the reaction system to 7.5 with hydrochloric acid and sodium hydroxide aqueous solution, add 1mg of PMX-53 to the gelatin aqueous solution, stir magnetically at 800rmp / min for 3min, and magnetically stir at 1500rmp / min Add 40mL of acetone to the above system to emulsify the system to form gelatin particles under certain conditions, add 400 μL of 50% glutaraldehyde aqueous solution, and stir in an ice bath for 12 hours to solidify the gelatin particles; centrifuge at 15000rmp, remove the supernatant, and use acetone The precipitate was cleaned 4 times under ultrasound, and vacuum-dried to obtain com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com