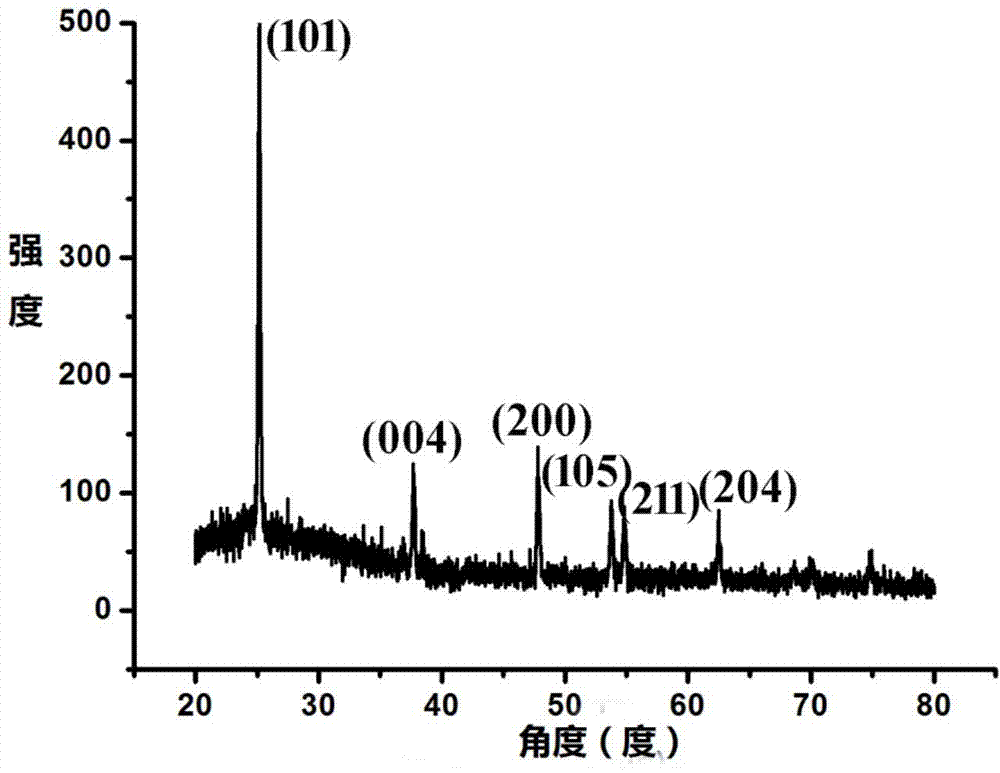

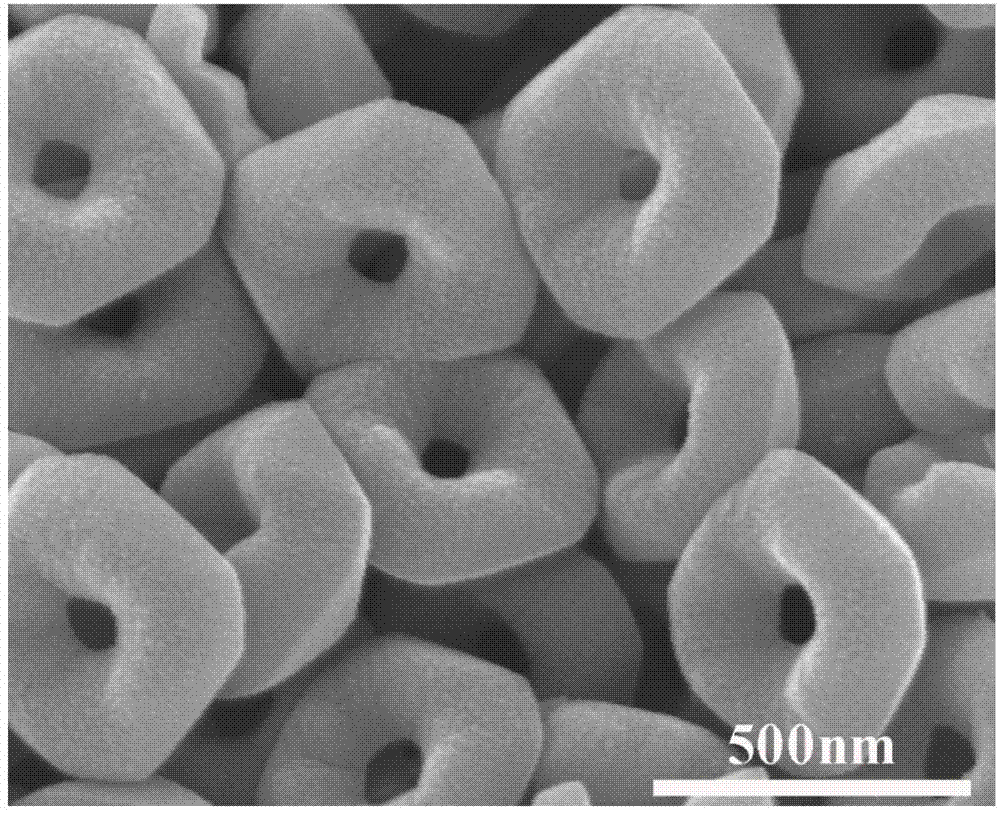

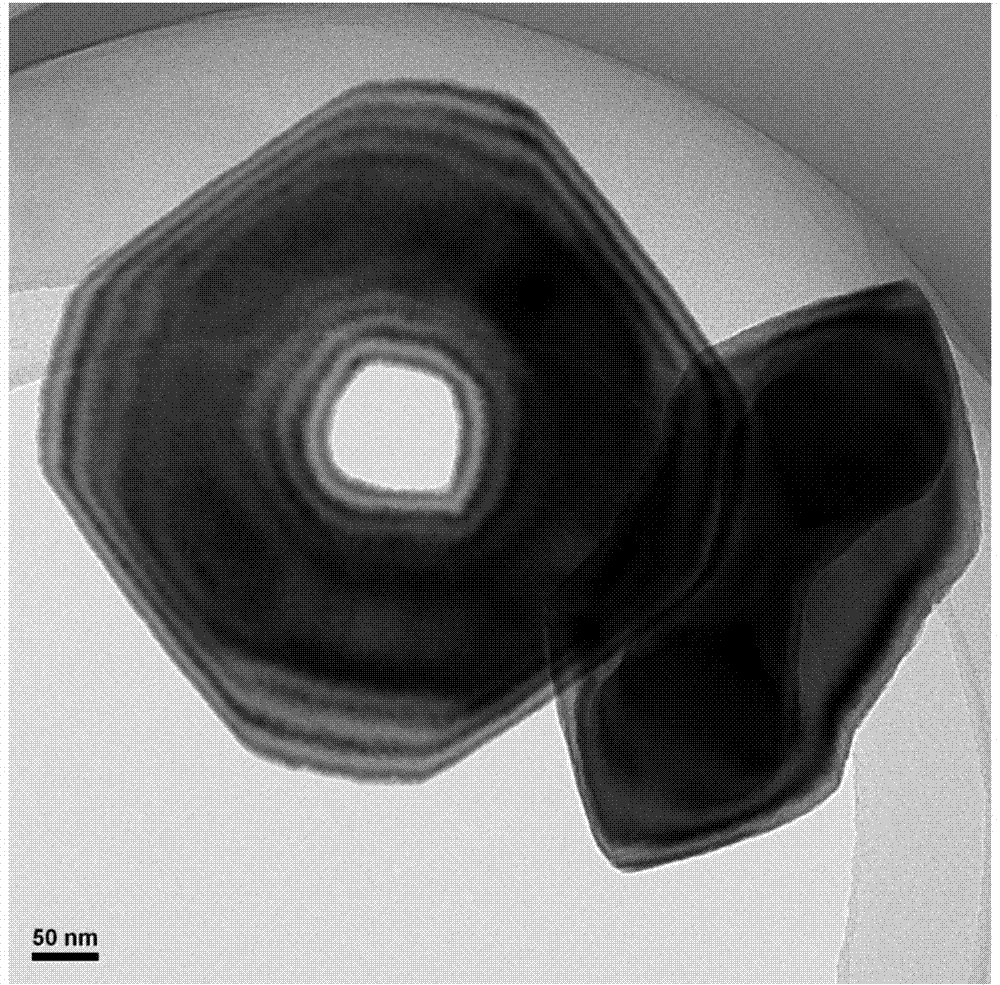

Method for preparing ultrafine powder in nano titanium dioxide structure

A nanostructure, titanium dioxide technology, applied in the direction of chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of long time period, high cost, poor uniformity, etc., achieve short time, low cost, Good uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Take a certain amount of ultrapure water at normal temperature and pressure and add it to a polytetrafluoroethylene liner with a total volume of 52ml, then add a certain amount of titanium powder, hydrogen peroxide and hydrofluoric acid respectively to obtain a hydrothermally synthesized mixture. Material, the molar ratio of the batching consumption of titanium powder and ultrapure water is 1:7500, the molar concentration of hydrogen peroxide is 1.53mol / L, and the molar ratio of hydrofluoric acid and hydrogen peroxide is 1:14.36;

[0028] 2) Seal the mixture obtained in step 1) in a stainless steel reaction kettle, then place the sealed stainless steel reaction kettle in a digital blast oven, react at 180°C for 6.5h, and then naturally cool to room temperature to obtain a milky white product The suspension was collected, and dried in a drying oven at 80°C for 1 hour to obtain a titanium dioxide polyhedral active precursor;

[0029] 3) Add a certain amount of ultrapur...

Embodiment 2

[0038] 1) Take a certain amount of ultrapure water at normal temperature and pressure and add it to a polytetrafluoroethylene liner with a total volume of 52ml, then add a certain amount of titanium powder, hydrogen peroxide and hydrofluoric acid respectively to obtain a hydrothermally synthesized mixture. Material, the molar ratio of the batching consumption of titanium powder and ultrapure water is 1:7500, the molar concentration of hydrogen peroxide is 1.55mol / L, and the molar ratio of hydrofluoric acid and hydrogen peroxide is 1:14.36;

[0039] 2) Seal the mixture obtained in step 1) in a stainless steel reaction kettle, then place the sealed stainless steel reaction kettle in a digital blast oven, react at 180°C for 6.5h, and then naturally cool to room temperature to obtain a milky white product The suspension was collected, and dried in a 60°C drying oven for 1 hour to obtain a titanium dioxide polyhedral active precursor;

[0040] 3) Add a certain amount of ultrapure w...

Embodiment 3

[0043] 1) Take a certain amount of ultrapure water at normal temperature and pressure and add it to a polytetrafluoroethylene liner with a total volume of 52ml, then add a certain amount of titanium powder, hydrogen peroxide and hydrofluoric acid respectively to obtain a hydrothermally synthesized mixture. Material, the molar ratio of the batching consumption of titanium powder and ultrapure water is 1:7500, the molar concentration of hydrogen peroxide is 1.53mol / L, and the molar ratio of hydrofluoric acid and hydrogen peroxide is 1:14.36;

[0044] 2) Seal the mixture obtained in step 1) in a stainless steel reaction kettle, then place the sealed stainless steel reaction kettle in a digital blast oven, react at 170° C. for 7 hours, and then naturally cool to room temperature to obtain a milky white product. Suspension, collect the product, and dry in an 80°C drying oven for 1 hour to obtain a titanium dioxide polyhedral active precursor;

[0045] 3) Add a certain amount of ult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com