Enhancer for touch screen edge enhancing process

A strengthening agent and touch screen technology, which is applied in the field of strengthening agent of touch screen edge strengthening process, can solve the problems of easy cracking, poor mass production, insufficient strength, etc., and achieve the effect of improving solubility, eliminating micro cracks and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] In the mixing tank, add 16Kg of pure water and 32Kg of sulfuric acid with a concentration of 70% successively, and stir under air pressure for 180s to make the two liquids mix evenly; Mix the three liquids evenly; then add 3.2Kg of 49% hydrofluoric acid into the mixing tank, and stir for 180s under air pressure to make the four liquids mix evenly; then add 636g of 99% acetic acid into the mixing tank, and stir under air pressure for 180s , make five kinds of liquids mix evenly; Add 31g37% concentration hydrochloric acid in the mixing tank at last, air pressure stirs 2H, promptly make a kind of for touch screen edge strengthening process provided by the present invention after making six kinds of liquids fully mix uniformly enhancer.

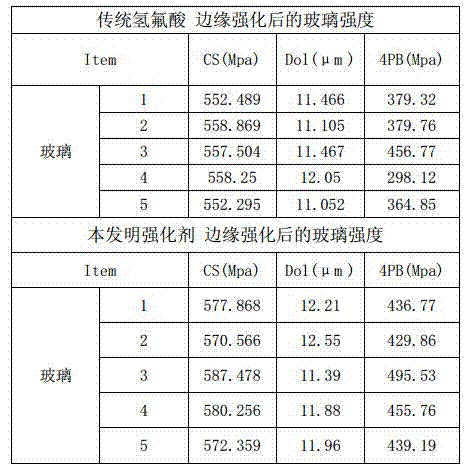

[0009] Take 5 pieces of Asahi Glass with a thickness of 0.55mm and immerse them in the prepared strengthening agent for edge strengthening, and another 5 pieces of Asahi Glass with a thickness of 0.55mm are immersed in traditional single h...

Embodiment 2

[0012] Add 18.3Kg of pure water and 32Kg of sulfuric acid with a concentration of 70% in sequence in the mixing tank, and stir under air pressure for 180s to make the two liquids mix evenly; Mix the three liquids evenly; then add 4.89Kg of 49% hydrofluoric acid into the mixing tank, and stir for 180s under air pressure to mix the four liquids evenly; then add 858g of 99% acetic acid into the mixing tank, and stir under air pressure 180s, the five kinds of liquids were mixed evenly; finally, 46g of hydrochloric acid with a concentration of 37% was added to the mixing tank, and the air pressure was stirred for 2H, and after the six kinds of liquids were fully mixed evenly, a kind of edge strengthening process for touch screen provided by the present invention was obtained. enhancer.

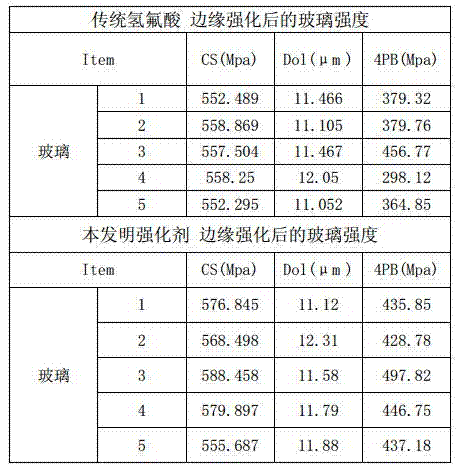

[0013] Take 5 pieces of Asahi Glass with a thickness of 0.55mm and immerse them in the prepared strengthening agent for edge strengthening, and another 5 pieces of Asahi Glass with a thickness of 0...

Embodiment 3

[0016] Add 19.2Kg of pure water and 35Kg of sulfuric acid with a concentration of 70% in sequence in the mixing tank, and stir under air pressure for 180s to make the two liquids mix evenly; Mix the three liquids evenly; then add 6.39Kg of 49% hydrofluoric acid into the mixing tank, and stir for 180s under air pressure to mix the four liquids evenly; then add 953g of 99% acetic acid into the mixing tank, and stir under air pressure 180s, the five kinds of liquids were mixed evenly; finally, 61g of hydrochloric acid with a concentration of 37% was added to the mixing tank, and the air pressure was stirred for 2H, and after the six kinds of liquids were fully mixed evenly, a kind of edge strengthening process for touch screen provided by the present invention was obtained. enhancer.

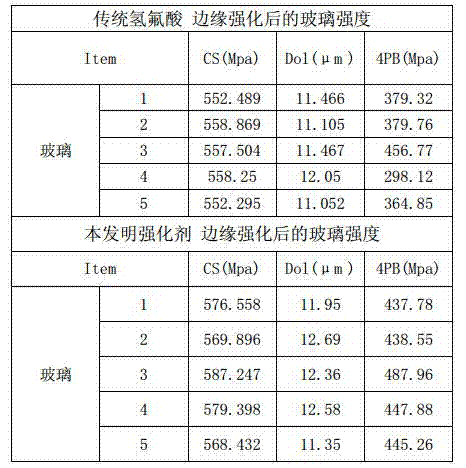

[0017] Take 5 pieces of Asahi Glass with a thickness of 0.55mm and immerse them in the prepared strengthening agent for edge strengthening, and another 5 pieces of Asahi Glass with a thickness of 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com