Preparation method of leather meal cement foaming agent

A technology of cement foaming agent and leather scraps, which is applied in the field of preparation of protein-based cement foaming agent, can solve the problems of high production cost of surfactants, cure the symptoms but not the root cause, and achieve the advantages of low price, lower production cost and control cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

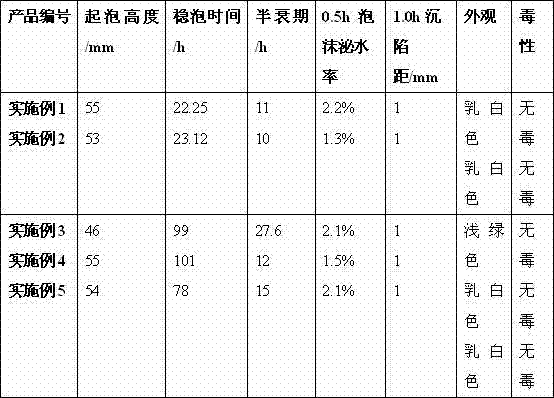

Examples

Embodiment 1

[0023] (1) Add the following raw materials in a 250ml three-necked bottle: 40g water, 4g leather shavings (dry weight), 0.3g sodium hydroxide and 0.3g madecassoside, and react under stirring at 80°C 7h, suction filtration under reduced pressure, and centrifugation to obtain the stock solution of the hydrolyzate;

[0024] (2) Adjust the pH of the above-mentioned hydrolyzate stock solution to 6.5, then add 35g of water, and mix evenly to obtain the animal protein cement foaming agent base solution;

[0025] (3), add 0.5g of gum arabic powder, 0.3g of sodium lauryl sulfate, 0.3g of sodium lauryl alcohol ether sulfate and 1 to the animal protein cement foaming agent base liquid obtained in step (2), 0.6 g of 8-dihydroxy-3-carboxyanthraquinone was uniformly mixed at room temperature for 60 minutes to obtain a foaming agent for leather shavings cement.

Embodiment 2

[0027] (1) Add the following raw materials in a 250ml three-necked bottle: 50g water, 6g leather shavings (dry weight), 1g calcium hydroxide and 4.1g madecassoside, react at 100°C for 9h , suction filtration under reduced pressure, and centrifugation to obtain a hydrolyzate stock solution;

[0028] (2) Adjust the pH of the stock solution of the hydrolyzate to 7.5, then add 50 g of sulfuric acid solution with a mass fraction of 40%, and mix evenly to obtain the animal protein cement foaming agent base liquid;

[0029] (3), add 2.0g of triethanolamine, 1.0g of sodium dodecylbenzenesulfonate, 1.0g of sodium dodecyl polyoxyethyl ether sulfate and 1 to the animal protein cement foaming agent base liquid obtained in step (2), 2.1 g of 8-dihydroxy-3-carboxyanthraquinone was mixed and stirred at room temperature for 60 minutes to obtain a foaming agent for leather shavings cement.

Embodiment 3

[0031] (1) Add the following raw materials in a 250ml three-necked bottle: 45g of water, 5g of leather shavings (dry weight), 0.65g of potassium hydroxide and 2.2g of madecassoside, and react under stirring at 90°C 8h, suction filtration under reduced pressure, and centrifugation to obtain the stock solution of the hydrolyzate;

[0032] (2) Adjust the pH of the stock solution of the hydrolyzate to 7, then add 42.5 g of sodium hydroxide with a concentration of 30%, and mix evenly to obtain the base liquid of animal protein cement foaming agent;

[0033] (3) Add 1.25 g of gelatin, 0.65 g of sodium lauryl sulfate, 0.65 g of sodium lauryl polyoxyethylene ether sulfate and 1,8- 1.4 g of dihydroxy-3-carboxyanthraquinone was mixed and stirred at room temperature for 60 minutes to obtain a foaming agent for leather shavings cement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com