Preparation method for microbial lipid-based polyhydric alcohol

A technology of microbial oils and polyalcohols, which is applied in the preparation of organic compounds, carboxylate salts, carboxylate esters, etc., can solve the problem of low epoxy value of epoxidized products, achieve low production costs, and overcome production cycles Long-term, good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Preparation of a microbial oil-based polyol product, take 10g epoxy microbial oil (epoxy value 3.0); methanol 1g; catalyst concentrated sulfuric acid 0.01g; add in the reactor, heat in a water bath, heat up to 40°C, and react for 1 hour The reaction is terminated with sodium carbonate solution, and the obtained crude product is washed with hot water to make the solution neutral; the washed product is distilled and dehydrated under reduced pressure to obtain microbial oil-based polyols.

Embodiment 2

[0026] Referring to Example 1, the differences are: methanol 6g, catalyst fluoroboric acid 0.04g; reaction temperature 60°C; reaction time 2 hours.

Embodiment 3

[0028] Referring to Example 1, the differences are: 12 g of ethanol, 0.05 g of concentrated nitric acid as a catalyst; a reaction temperature of 65° C.; and a reaction time of 4 hours.

PUM

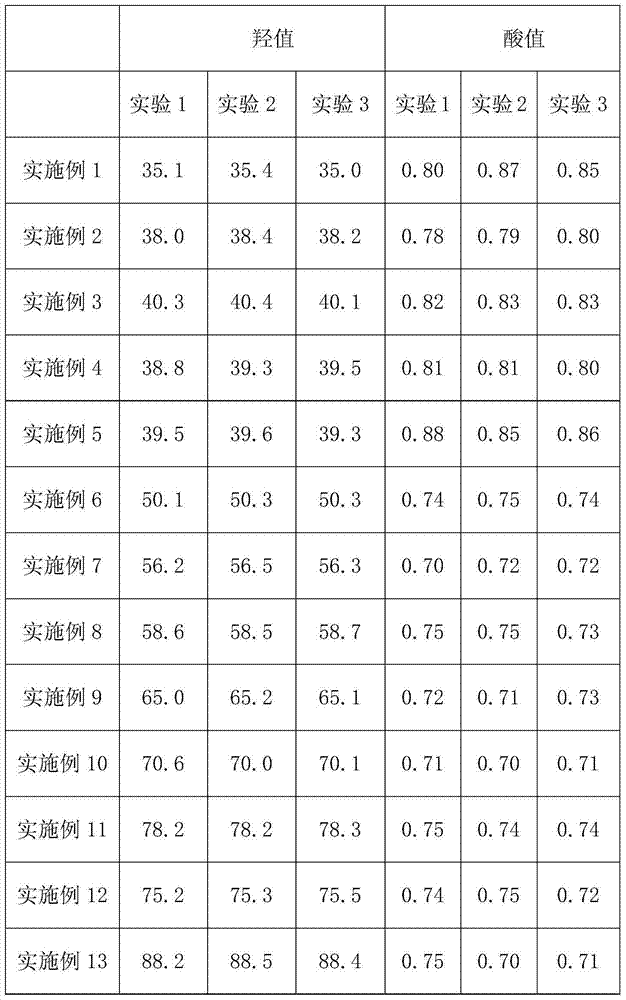

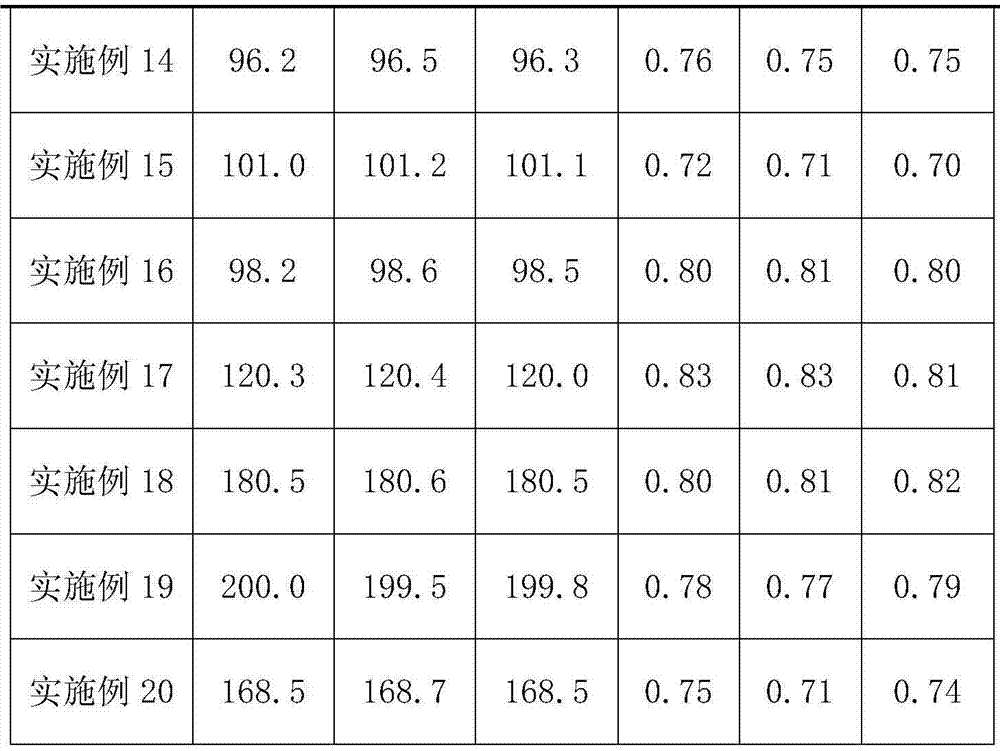

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com