Preparation method of S-2-(4-methoxyphenoxy) sodium propionate

A technology of methoxyphenoxy and p-methoxyphenol, which is applied in the field of preparation of sweetness inhibitors, can solve problems such as food sweetness, and achieve the effects of eliminating potential hazards, good sweetness suppression effect, and reducing metabolic burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

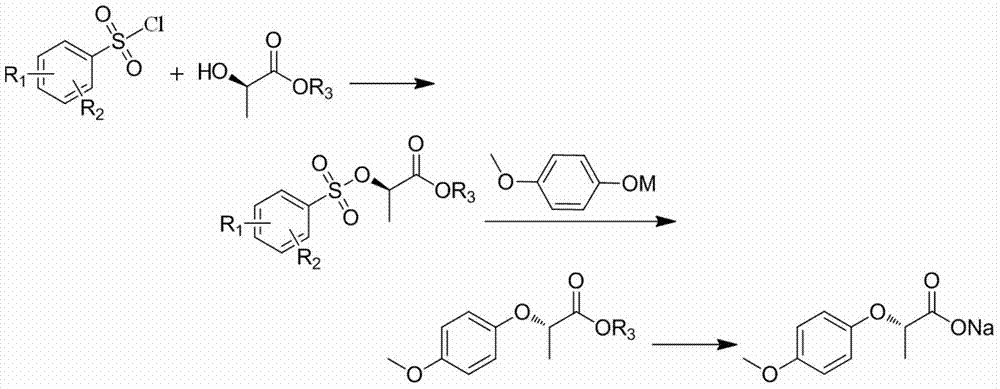

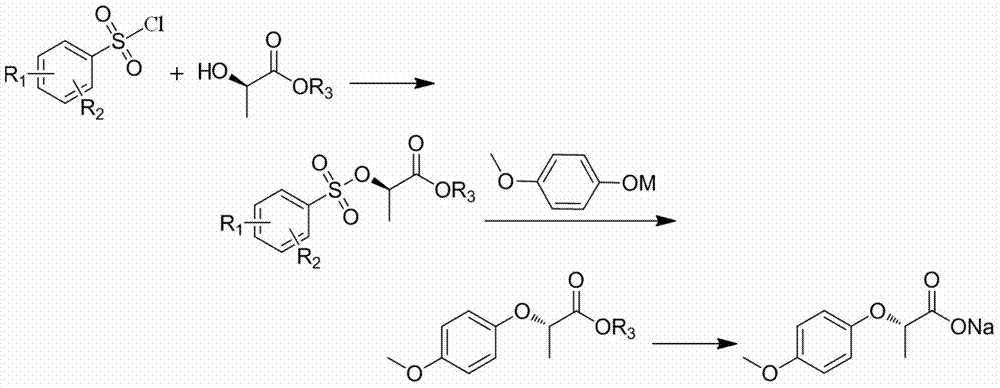

Method used

Image

Examples

Embodiment 1

[0027] 1) Add 13.70 g (0.072 mol) of p-toluenesulfonyl chloride, 7.80 g (0.075 mol) of methyl D-lactate, and 30 mL of toluene into a 150 mL two-necked flask, add 11.4 g of triethylamine dropwise, and react for 12 hours to complete the reaction. Filter, wash with water (30mL×2), dry the organic phase with anhydrous sodium sulfate, evaporate the solvent to obtain methyl R-2-(4-methylbenzenesulfonate)propionate.

[0028] 2) Add 30g of dichloromethane, 4.380g (0.03mol) of sodium p-methoxyphenate, 0.32g (0.001mol) of tetra-n-butylammonium bromide into a 250mL two-necked flask, and then dropwise add the resulting R- 7.74 g (0.03 mol) of methyl 2-(4-methylbenzenesulfonate) propionate and 20 g of dichloromethane mixed solution were heated and refluxed for 20 hours.

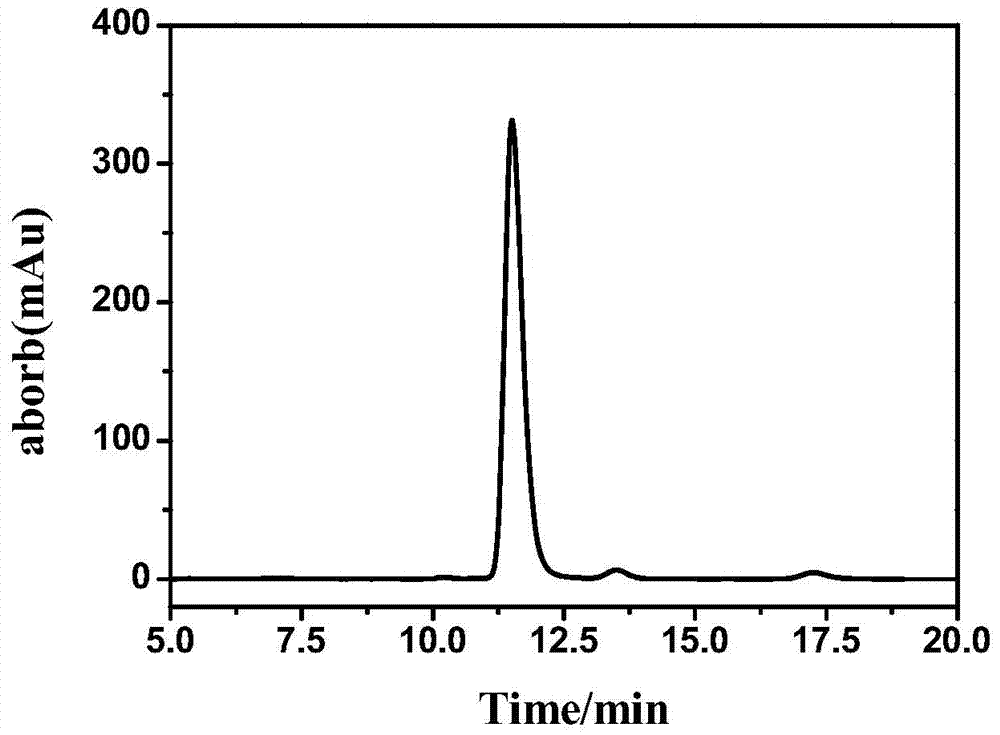

[0029] 3) Then add 1.5g of sodium hydroxide and 15mL of water to the solution, reflux for hydrolysis, point the plate to follow the reaction, after the hydrolysis is complete, separate the liquid to collect the water phas...

Embodiment 2

[0031] 1) Add 12.72 g (0.072 mol) of benzenesulfonyl chloride, 8.85 g (0.075 mol) of D-ethyl lactate, and 30 mL of toluene into a 150 mL two-necked flask, add 11.4 g of triethylamine dropwise, and react for 12 hours to complete the reaction. Filter, wash with water (30mL×2), dry the organic phase with anhydrous sodium sulfate, evaporate the solvent to obtain R-2-ethyl benzenesulfonate propionate.

[0032] 2) Add 30g of ether, 4.38g (0.03mol) of sodium p-methoxyphenate, 0.32g (0.001mol) of tetra-n-butylammonium bromide into a 250mL two-necked flask, and then add R-2-benzenesulfonate dropwise into the flask A mixture of 7.74 g (0.03 mol) of ethyl propionate and 20 g of diethyl ether was refluxed for 20 hours.

[0033] 3) Then add 1.5g of sodium hydroxide and 15mL of water to the solution, reflux for hydrolysis, spot the plate to track the reaction, after the hydrolysis is complete, distill off ether at 30°C, collect the water phase and adjust the pH of the water phase to about 2...

Embodiment 3

[0035] 1) Add 14.69g (0.072mol) of p-ethylbenzenesulfonyl chloride, 9.90g (0.075mol) of D-n-propyl lactate, and 30mL of toluene into a 150mL two-necked flask, add 11.4g of triethylamine dropwise, and react for 12 hours to complete the reaction . Filter, wash with water (30mL×2), dry the organic phase with anhydrous sodium sulfate, and distill off the solvent to obtain R-2-(4-ethylbenzenesulfonate)propyl propionate.

[0036] 2) Add 30g of dichloromethane, 4.38g (0.03mol) of sodium p-methoxyphenate, 0.32g (0.001mol) of tetra-n-butylammonium bromide into a 250mL two-necked flask, and then add R-2- 9.00 g (0.03 mol) of (4-ethylbenzenesulfonate) propyl propionate, and 20 g of dichloromethane. Heated and refluxed for 20 hours.

[0037]3) Then add 1.5g sodium hydroxide to the solution, reflux for hydrolysis, spot the plate to track the reaction, after the hydrolysis is complete, adjust the pH of the solution to about 2 with dilute hydrochloric acid solution, separate the liquids, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com