Lithium ion-type supercapacitor ternary composite negative electrode material and preparation method thereof

A technology for supercapacitors and negative electrode materials, which is used in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, and can solve the problems of low conductivity of lithium titanate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

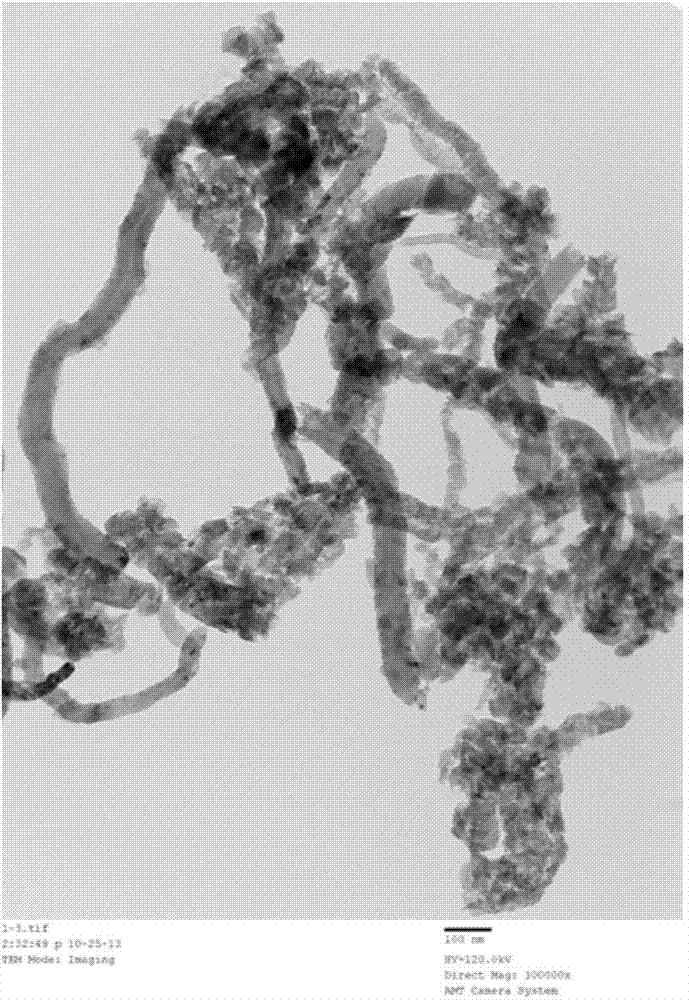

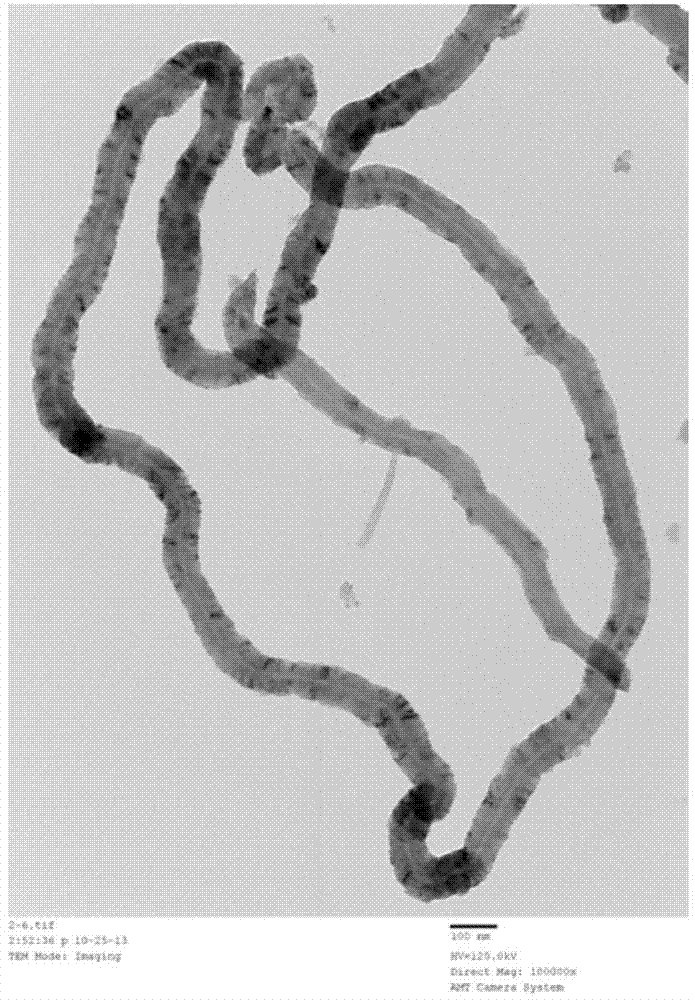

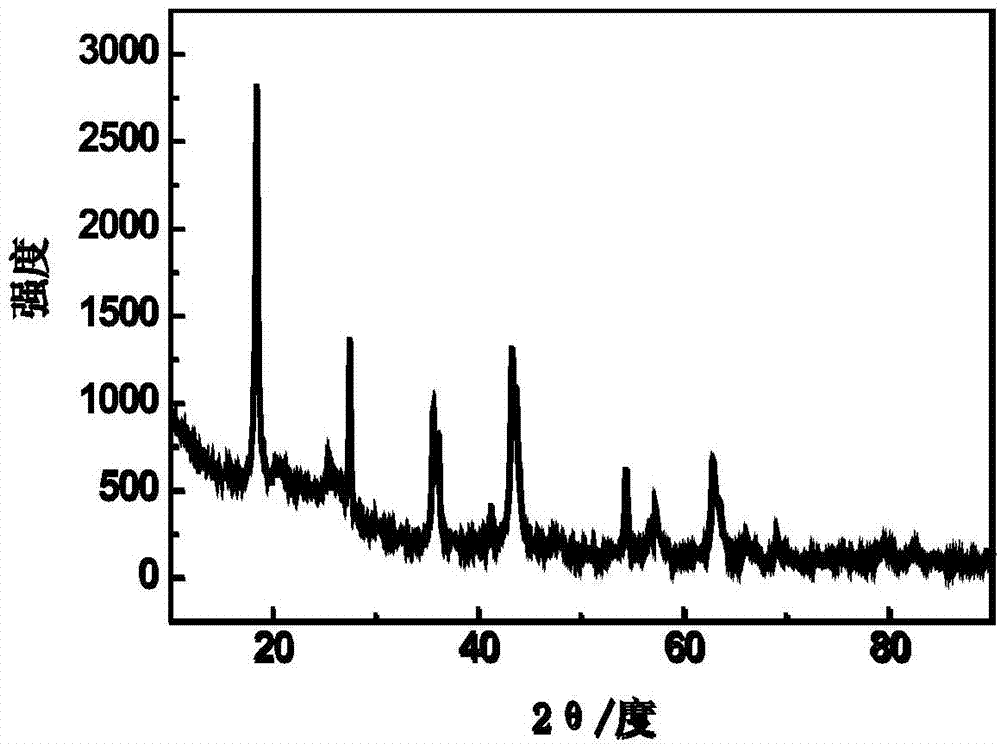

[0036] Sinter 0.4g of carbon nanotubes at 500°C for 30min, then disperse in a mixed solution of 30ml of concentrated nitric acid and 10ml of concentrated sulfuric acid, heat to 70°C, ultrasonicate for 3h, then wash with distilled water and centrifuge 5 times until neutral, then filter with suction . The morphology of carbon nanotubes before and after purification is as follows: figure 1 and figure 2shown. The purified carbon nanotubes were mixed with 20 ml of 5% sodium dodecylbenzenesulfonate and sonicated for 4 h, and ethanol was added and stirred for 30 min. Dissolve 7.4074g of tetrabutyl titanate in a mixed solution of 15ml of ethanol and 2ml of glacial acetic acid, stir for 30min, then add the tetrabutyl titanate solution dropwise to the carbon nanotube suspension, stir for 2h, add dropwise 35 % ammonia water, adjust pH=9, react for 1h, and generate a sol. The product was centrifuged three times with ethanol, washed with distilled water and centrifuged five times, and...

Embodiment 2

[0038] 0.4g of carbon nanotubes were sintered at 500°C for 30min, then dispersed in a mixed solution of 30ml of concentrated nitric acid and 10ml of concentrated sulfuric acid, heated to 70°C, sonicated for 3h, then washed with distilled water and centrifuged for 5 times until neutral, suction filtered . The morphology of carbon nanotubes before and after purification is as follows figure 1 and figure 2 shown. The purified carbon nanotubes were mixed with 20 ml of 5% sodium dodecylbenzenesulfonate and sonicated for 4 h, and ethanol was added and stirred for 30 min. Dissolve 7.4074g of tetrabutyl titanate in a mixed solution of 15ml of ethanol and 2ml of glacial acetic acid, stir for 30min, then add the tetrabutyl titanate solution dropwise to the carbon nanotube suspension, stir for 2h, add dropwise 35 % ammonia water, adjust pH=9, react for 1h, and generate a sol. The product was centrifuged three times with ethanol, washed with distilled water and centrifuged five times...

Embodiment 3

[0040] 0.4g of carbon nanotubes were sintered at 500°C for 30min, then dispersed in a mixed solution of 30ml of concentrated nitric acid and 10ml of concentrated sulfuric acid, heated to 70°C, sonicated for 3h, then washed with distilled water and centrifuged for 5 times until neutral, suction filtered . The morphology of carbon nanotubes before and after purification is as follows figure 1 and figure 2 shown. The purified carbon nanotubes were mixed with 20 ml of 5% sodium dodecylbenzenesulfonate and sonicated for 4 h, and ethanol was added and stirred for 30 min. Dissolve 7.4074g of tetrabutyl titanate in a mixed solution of 15ml of ethanol and 2ml of glacial acetic acid, stir for 30min, then add the tetrabutyl titanate solution dropwise to the carbon nanotube suspension, stir for 2h, add dropwise 35 % ammonia water, adjust pH=9, react for 1h, and generate a sol. The product was centrifuged three times with ethanol, washed with distilled water and centrifuged five times...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com