Propylene resin composition for retort pouch-packaging film

A technology of propylene resin and composition, applied in the production of adhesives and bulk chemicals, etc., can solve the problems of poor dispersion of rubber components, narrow molecular weight distribution, and no mention of it

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

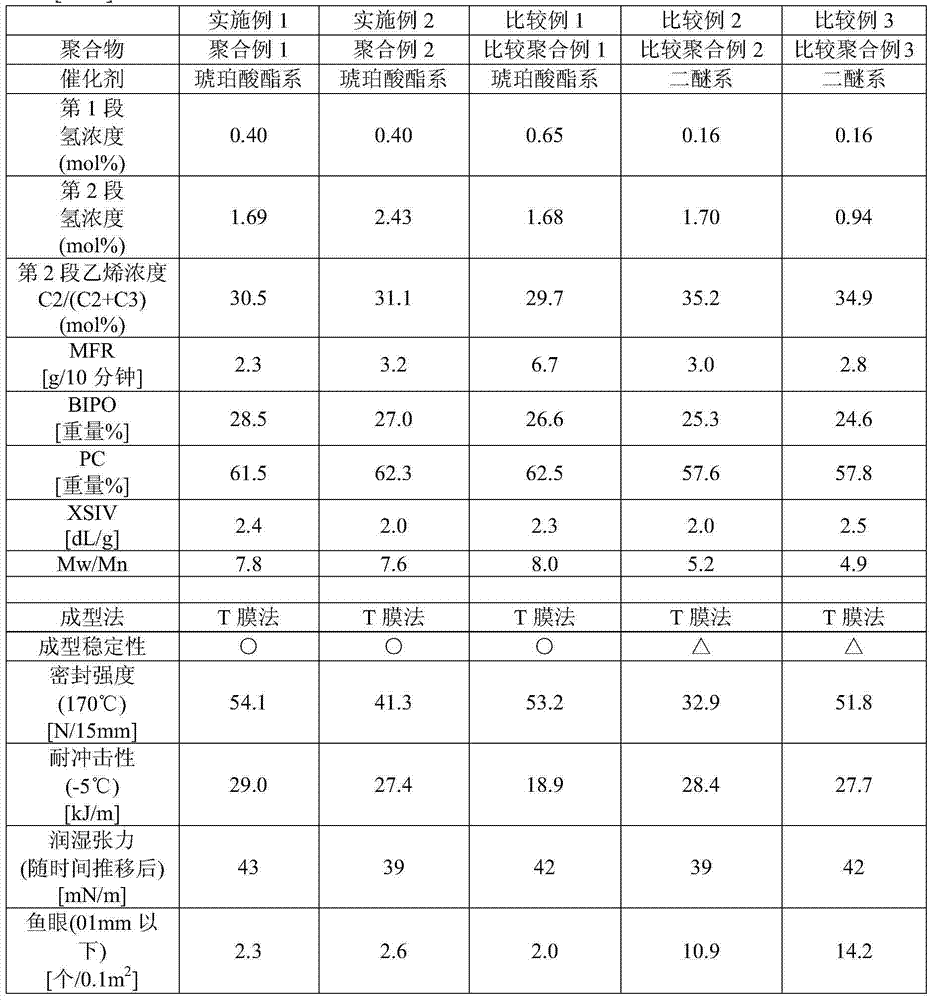

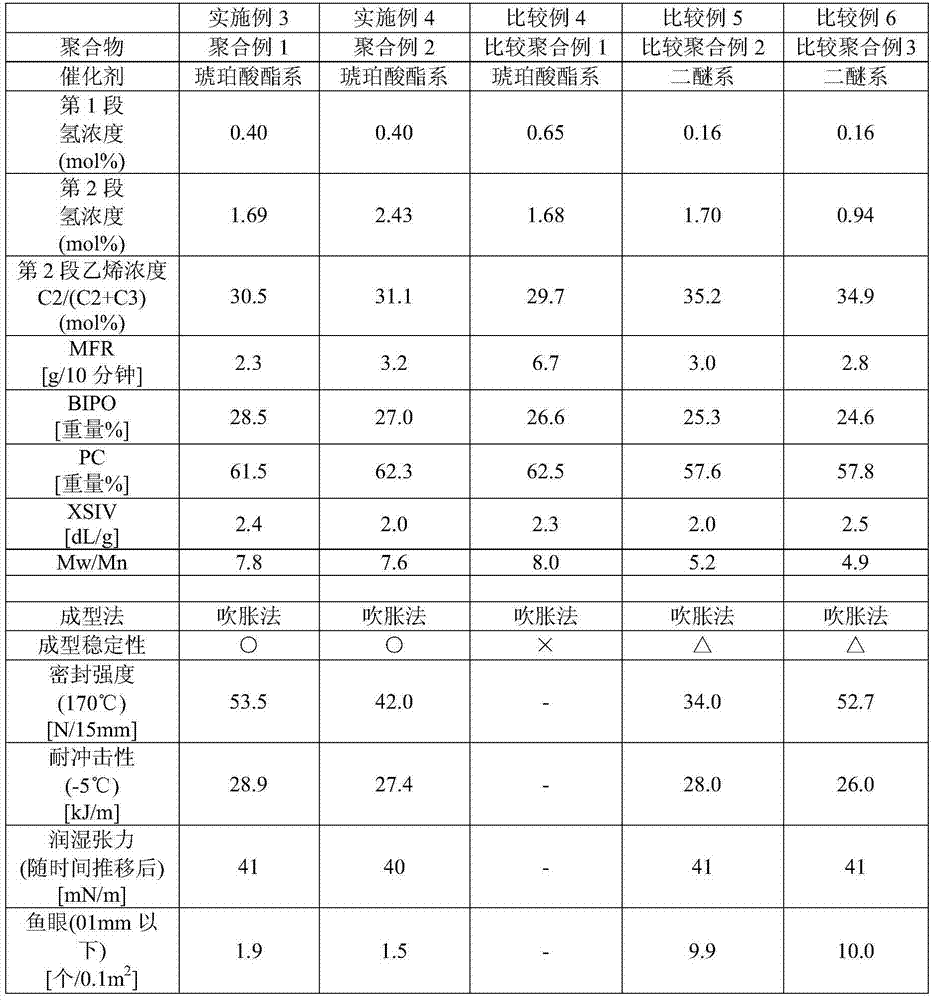

[0087] The following examples are given to further illustrate the present invention. In addition, each analysis in an Example was performed by the following method.

[0088] [MFR]

[0089] According to JIS K 7210, it measured on the conditions of temperature 230 degreeC, and load 21.18N.

[0090] [Propylene Concentration in Copolymer]

[0091] For the sample dissolved in a mixed solvent of 1,2,4-trichlorobenzene / deuterated benzene, JNM LA-400 ( 13 C resonant frequency is 100MHz), through 13 C-NMR method for determination.

[0092] [Xylene insoluble components]

[0093] Add 2.5 g of the propylene resin composition to a flask with 250 mL of o-xylene (solvent), and use a heating plate and a reflux device to perform nitrogen purge at 135° C. while stirring for 30 minutes to completely dissolve the resin composition. , cooled at 25°C for 1 hour. The obtained solution was filtered using filter paper. Acetone was added to the residue remaining on the filter paper at this time...

Embodiment 3 and 4 and comparative example 4~6

[0141] The propylene resin compositions obtained in Polymerization Examples 1 and 2 and Comparative Polymerization Examples 1 to 3 were molded by an inflation method to produce a sealing film with a thickness of 60 μm.

[0142] The properties of the propylene resin compositions obtained in the respective polymerization examples and comparative polymerization examples and the properties of the obtained films are summarized in Table 2 below as Examples 3 and 4 and Comparative Examples 4 to 6.

[0143] [Table 2]

[0144]

[0145] Compared with the propylene resin composition of Comparative Example, the propylene resin composition of the present invention has high molding stability. When the propylene resin compositions of Comparative Polymerization Examples 2 and 3 were molded, some sloshing of bubbles was observed. In addition, when the propylene resin composition of Comparative Polymerization Example 1 was molded, the bubble sloshing was large, and a film sample could not b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com