Passenger car floor of sandwich structure

A passenger car floor and sandwich structure technology, which is applied in the field of automobile interior decoration and composite materials, can solve the problems that the passenger car floor cannot fully meet the use requirements, the performance of PVC material is reduced, and it is easy to break, so as to achieve excellent installation reliability and convenient installation. Installation and maintenance, to solve the effect of short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

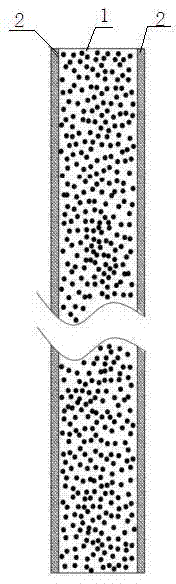

[0015] Such as figure 1 As shown, a passenger car floor with a sandwich structure, the passenger car floor has a surface layer 2, a core material 1 and a surface layer 2 arranged from top to bottom; the surface layer 2 is a glass fiber fabric reinforced resin-based composite Material layer; the glass fiber fabric reinforced resin-based composite material layer is prepared with glass fiber grid cloth as a reinforcement, and resin is used as a matrix by pultrusion or molding, and the glass fiber fabric reinforced resin-based composite material layer is 2 has a thickness of 0.5mm and a density of 1900kg / m 3 ; The mass fraction of glass fiber grid cloth in the glass fiber fabric reinforced resin matrix composite material layer is 58%; The described core material 1 uses glass fiber direct yarn as reinforcement, and the rigid polyurethane formed by foaming polyurethane resin Foam plastic is prepared by molding or rolling die or pultrusion as the matrix; the thickness of the core ma...

Embodiment 2

[0019] A passenger car floor with a sandwich structure, the passenger car floor has a surface layer 2, a core material 1 and a surface layer 2 arranged from top to bottom; the surface layer 2 is a glass fiber fabric reinforced resin-based composite material layer; The glass fiber fabric-reinforced resin-based composite material layer uses glass fiber grid cloth as a reinforcement, and the resin is used as a matrix to prepare and form it by pultrusion or molding. The thickness of the glass fiber fabric-reinforced resin-based composite material layer 2 is 0.5mm, density 1920kg / m 3 ; The mass fraction of glass fiber grid cloth in the glass fiber fabric reinforced resin matrix composite material layer is 52%; The described core material 1 uses glass fiber direct yarn as a reinforcement, and the rigid polyurethane formed by polyurethane resin foaming Foam plastic is prepared by molding or rolling die or pultrusion as the matrix; the thickness of the core material is 9mm, and the de...

Embodiment 3

[0023] A passenger car floor with a sandwich structure, the passenger car floor has a surface layer 2, a core material 1 and a surface layer 2 arranged from top to bottom; the surface layer 2 is a glass fiber fabric reinforced resin-based composite material layer; The glass fiber fabric-reinforced resin-based composite material layer uses glass fiber grid cloth as a reinforcement, and the resin is used as a matrix to prepare and form it by pultrusion or molding. The thickness of the glass fiber fabric-reinforced resin-based composite material layer 2 is 0.5mm, density 2016kg / m 3 ; The mass fraction of glass fiber grid cloth in the glass fiber fabric reinforced resin matrix composite material layer is 66%; The described core material 1 uses glass fiber direct yarn as a reinforcement, and the rigid polyurethane formed by foaming polyurethane resin Foam plastic is prepared by molding or rolling die or pultrusion as the matrix; the thickness of the core material is 9mm, and the de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com