Refining process of crude selenium

A crude selenium and process technology, applied in the direction of elemental selenium/tellurium, etc., can solve the problems of complex crude selenium refining process, a large amount of toxic and harmful gases, and many chemical reagents, so as to reduce production costs, consume less raw materials, and facilitate operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

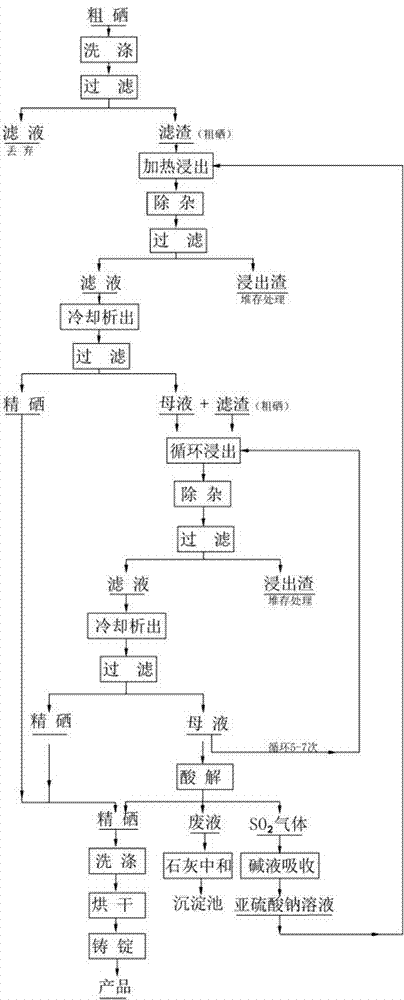

[0035] see figure 1 , the crude selenium raw material in the present embodiment is that the crude selenium content of selenium produced in the copper anode sludge sulfation roasting process is 50%, and the technique of the present invention comprises the following steps:

[0036] (1) Crude selenium washing: After washing the crude selenium raw material and water in a weight ratio of 1:1, add water for 2-3 times, filter and store the filter residue for later use;

[0037] (2) Crude selenium leaching: add 3m 3 Sodium sulfite solution with a concentration of 150g / l, heated to 95-100°C and reacted for 2-3 hours, replenished water appropriately, then added ammonium sulfide until no precipitation occurred in the solution, filtered the solution after standing for 2 hours, and the filtrate was to be treated; the filter residue was washed with water to pH After =7.0-7.5, the eluate is used as the reaction replenishment water in step (2);

[0038] (3) Precipitation of refined selenium...

Embodiment 2

[0043] see figure 1 , the crude selenium raw material in the present embodiment is that the crude selenium selenium content that produces in the copper anode slime sulfation roasting process is 62%, and technique of the present invention comprises the following steps:

[0044] (1) Crude selenium washing: After washing the crude selenium raw material and water in a weight ratio of 1:1, add water for 2-3 times, filter and store the filter residue for later use;

[0045] (2) Crude selenium leaching: add 4m per ton of filter residue in step (1) 3 For sodium sulfite solution with a concentration of 180g / l, heat it to 95-100°C for 2-3 hours, then add water appropriately, then add ammonium sulfide until no precipitation occurs in the solution, filter the solution after standing for 2 hours, and the filtrate is to be treated; the filter residue is washed with water to pH After =7.0-7.5, the eluate is used as the reaction replenishment water in step (2);

[0046] (3) Precipitation of...

Embodiment 3

[0051] see figure 1 , the crude selenium raw material in the present embodiment is the crude selenium produced in the anode slime oxidation roasting process, and the selenium content is 91%, and the technique of the present invention comprises the following steps:

[0052] (1) Crude selenium washing: After washing the crude selenium raw material and water in a weight ratio of 1:1, add water for 2-3 times, filter and store the filter residue for later use;

[0053] (2) Crude selenium leaching: add 8m 3 Sodium sulfite solution with a concentration of 250g / l, heated to 95-100°C and reacted for 2-3 hours, replenished water appropriately, then added ammonium sulfide until no precipitation occurred in the solution, filtered the solution after standing for 2 hours, and the filtrate was to be treated; the filter residue was washed with water to pH After =7.0-7.5, the eluate is used as the reaction replenishment water in step (2);

[0054] (3) Precipitation of refined selenium: After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com