Preparation method for NiCoP nano material

A technology of nanomaterials and distilled water, which is applied in the field of preparation of NiCoP nanomaterials, can solve the problems of difficult synthesis of bimetallic phosphides, high reaction temperature, and unsafety, and achieve good adsorption and removal performance, low reaction temperature, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of NiCoP nanomaterials, comprising the following steps:

[0025] 1) Weigh 5.8160g NiCl 2 ·6H 2 O and 5.8210 g CoCl 2 ·6H 2 O was dissolved in a beaker filled with 40mL distilled water, stirred and dissolved to form a uniform and transparent purple-red solution;

[0026] 2) Heat the above solution on a stirrer at a constant temperature of 60°C and stir rapidly until the water is completely removed, stop heating, use residual heat to completely dry the reactant, and grind the obtained product to 200-300 mesh powder for later use;

[0027] 3) transfer the ground powder obtained in step 2) to a porcelain boat, and calcinate in a muffle furnace at 500° C. for 1.5 h to obtain a black powder;

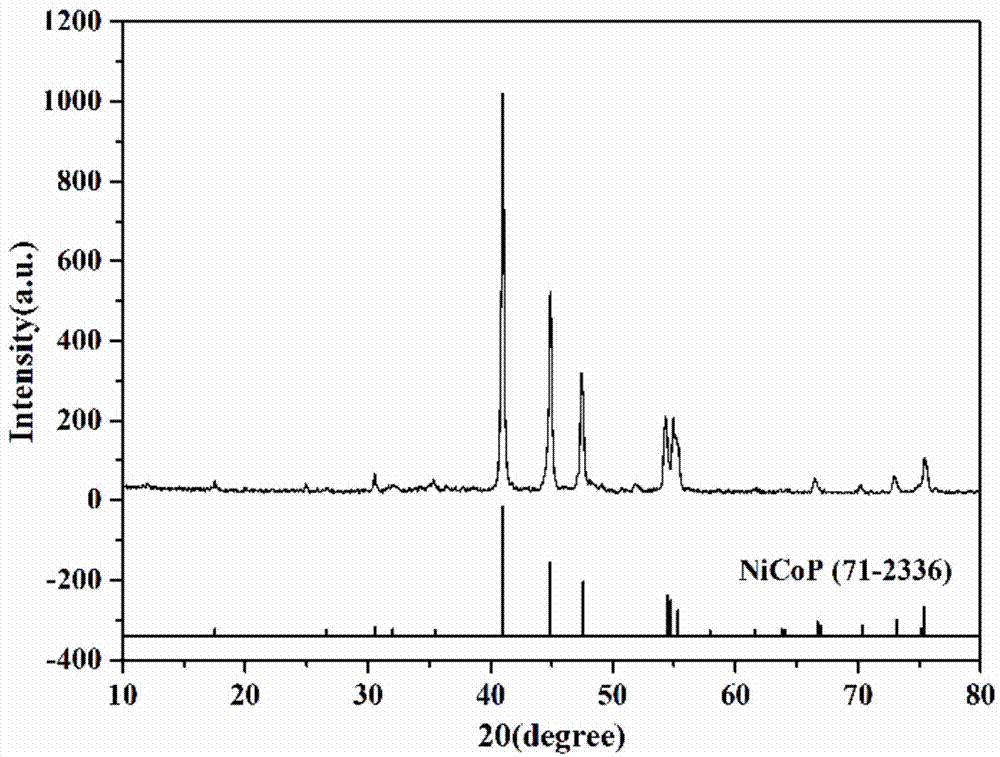

[0028] 4) the black powder that step 3) obtains and 6.3594g NH 4 h 2 PO 2 ·H 2 O mixed well, and in a high temperature tube furnace, under N 2 Heating at 250°C for 1 h under atmosphere to obtain the crude NiCoP product;

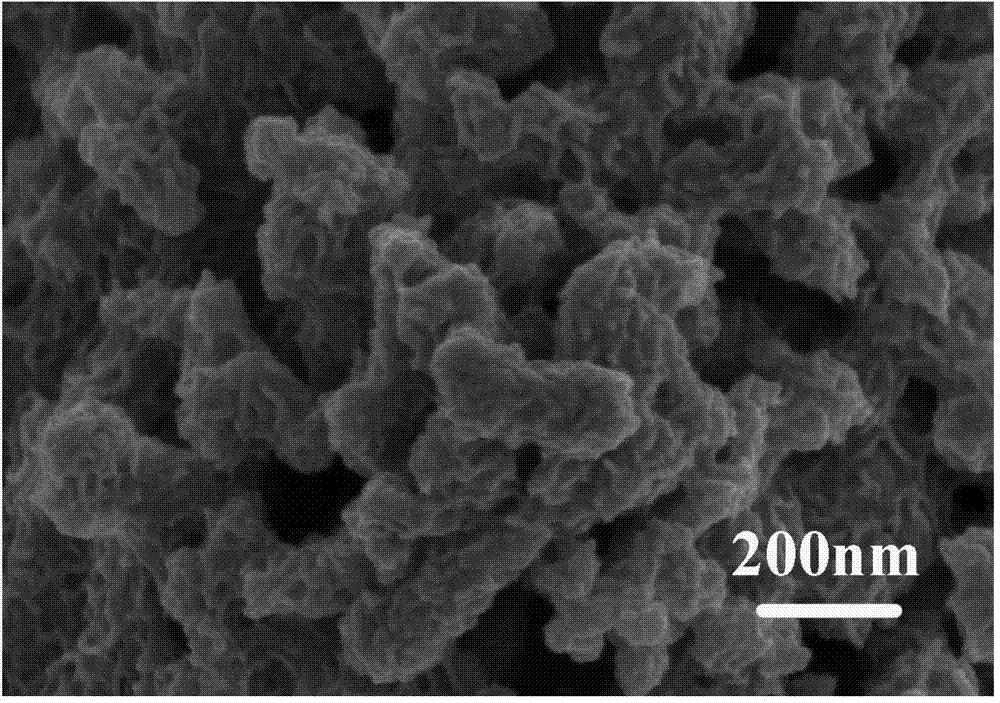

[0029] 5) Wash the crude NiCoP nan...

Embodiment 2

[0032] With the 5.8210g CoCl in the step 1) among the embodiment 1 2 ·6H 2 O changed to 4.8540g CoSO 4 ·7H 2 O, other conditions remain unchanged, sulfide impurities appear in the obtained NiCoP nanomaterials.

Embodiment 3

[0034] With the 5.8160g NiCl in the step 1) among the embodiment 1 2 ·6H 2 O and 5.8210 g CoCl 2 ·6H 2 O was changed to 5.2620g Ni(NO 3 ) 2 ·6H 2 O and 6.4780g Co(NO 3 ) 2 ·6H 2 O Other conditions remain unchanged, the obtained NiCoP nanomaterials are mainly NiCoP nanomaterials, but a small amount of cobalt phosphide impurities appear in the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com