Coating resistant to high temperature, high humidity and oxygen corrosion and preparation method thereof

A technology for corrosion coating and high temperature resistance, applied in the field of pyrochlore structure rare earth zirconium/hafnate coating and its preparation, can solve the problem of not being suitable for large-sized and complex-structured workpieces, affecting material reliability and protection performance, and thermal expansion High thermal and chemical stability, uniform and controllable coating thickness, and high catalytic activity can be achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

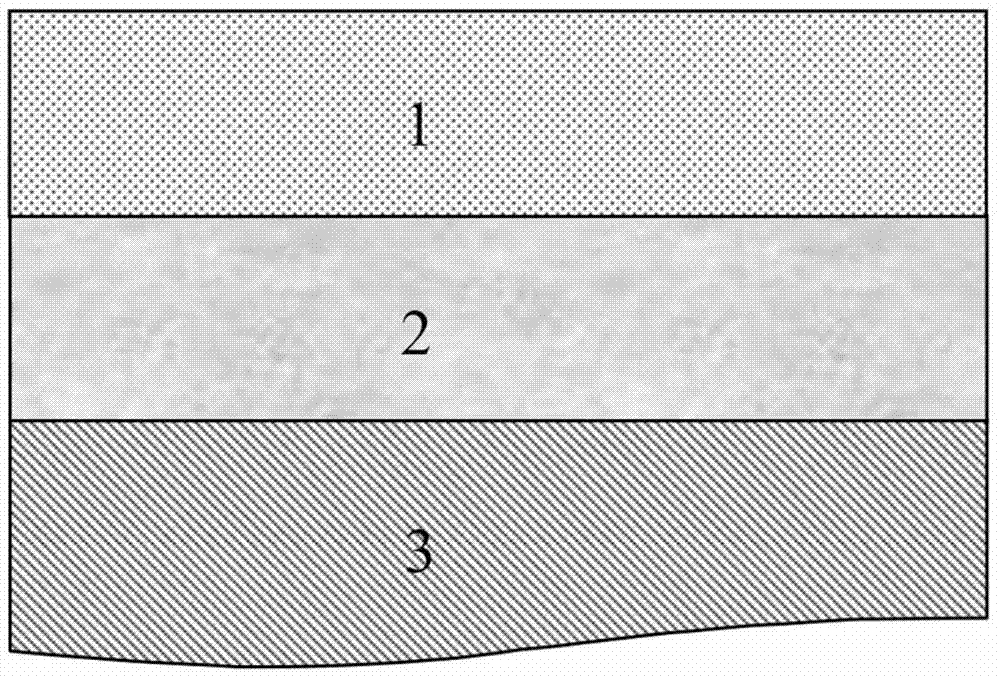

[0037] A kind of anti-high temperature wet oxygen corrosion coating of the present invention, such as figure 1 As shown, the coating is provided on the surface of the ceramic matrix composite material substrate 3, and the coating includes a bonding layer 2 and RE arranged sequentially from bottom to top. 2 x 2 o 7 Surface 1.

[0038] In this embodiment, the ceramic matrix composite material substrate 3 is a C / SiC composite material substrate, and the bonding layer 2 is SiO 2 Adhesive layer with a thickness of 10 μm. RE 2 x 2 o 7 Surface layer 1 is La 2 Zr 2 o 7 Surface layer with a thickness of 20 μm.

[0039] A preparation method of the above-mentioned high temperature, humidity and oxygen corrosion resistant coating of the present embodiment, comprising the following steps:

[0040] (1) Pretreatment of ceramic matrix composite substrate 3: Polish the surface of the C / SiC composite substrate, then perform ultrasonic cleaning, and then dry at 60°C (60-80°C can be im...

Embodiment 2

[0048] A kind of anti-high temperature wet oxygen corrosion coating of the present invention, such as figure 1 As shown, the coating is provided on the surface of the ceramic matrix composite material substrate 3, and the coating includes a bonding layer 2 and RE arranged sequentially from bottom to top. 2 x 2 o 7 Surface 1.

[0049]In this embodiment, the ceramic matrix composite material substrate 3 is a SiC / SiC composite material substrate, and the bonding layer 2 is a Si bonding layer with a thickness of 50 μm. RE 2 x 2 o 7 Surface layer 1 is Sm 2 Zr 2 o 7 coating with a thickness of 100 μm.

[0050] A preparation method of the above-mentioned high temperature, humidity and oxygen corrosion resistant coating of the present embodiment, comprising the following steps:

[0051] (1) Pretreatment of ceramic matrix composite substrate 3: Polish the surface of the SiC / SiC composite substrate, then perform ultrasonic cleaning, and then dry at 70°C (60-80°C can be impleme...

Embodiment 3

[0058] A kind of anti-high temperature wet oxygen corrosion coating of the present invention, such as figure 1 As shown, the coating is provided on the surface of the ceramic matrix composite material substrate 3, and the coating includes a bonding layer 2 and RE arranged sequentially from bottom to top. 2 x 2 o 7 Surface 1.

[0059] In this embodiment, the ceramic matrix composite material substrate 3 is a C / SiC composite material substrate, and the bonding layer 2 is a SiC bonding layer with a thickness of 100 μm. RE 2 x 2 o 7 Surface layer 1 is La 2 f 2 o 7 Surface layer with a thickness of 200 μm.

[0060] A preparation method of the above-mentioned high temperature, humidity and oxygen corrosion resistant coating of the present embodiment, comprising the following steps:

[0061] (1) Pretreatment of ceramic matrix composite substrate 3: Polish the surface of the C / SiC composite substrate, then perform ultrasonic cleaning, and then dry at 80°C (60-80°C can be imp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com